Global EPR Regulations by Product Category: Your Complete 2025 Compliance Guide

THIS BLOG WAS WRITTEN BY THE COMPLIANCE & RISKS MARKETING TEAM TO INFORM AND ENGAGE. HOWEVER, COMPLEX REGULATORY QUESTIONS REQUIRE SPECIALIST KNOWLEDGE. TO GET ACCURATE, EXPERT ANSWERS, PLEASE CLICK “ASK AN EXPERT.”

Extended Producer Responsibility (EPR) regulations are reshaping how businesses approach product lifecycle management across the globe. From packaging materials to electronics, batteries, textiles, and furniture, manufacturers and retailers must now navigate an increasingly complex web of compliance requirements that vary dramatically by region and product category.

This comprehensive guide cuts through the complexity by comparing EPR frameworks across all major product categories and jurisdictions. Whether you’re evaluating compliance obligations in the U.S., navigating the EU’s evolving packaging regulations, or preparing for emerging textile and furniture requirements, this resource provides the structured comparison framework you need to make informed compliance decisions.

You’ll discover actionable compliance pathways, understand critical deadlines and fee structures, and gain insights into emerging trends that will shape EPR requirements through 2030. This analysis draws from official regulatory sources, industry data, and expert insights to deliver the comprehensive perspective that fragmented government websites and single-jurisdiction resources simply cannot provide.

Table of Contents

- Understanding EPR: The Executive Overview

- The Global EPR Landscape: Current Status

- Packaging EPR: The Regulatory Leader

- Electronics EPR: Navigating WEEE Complexity

- Battery EPR: Power Source Responsibility

- Textiles and Furniture: The Next Frontier

- Producer Responsibility Organizations: Your Compliance Partners

- Fee Structures and Financial Planning

- Emerging Trends and Future Outlook

- Building Your Compliance Strategy

- Frequently Asked Questions

Understanding EPR: The Executive Overview

Extended Producer Responsibility represents a fundamental shift from traditional waste management approaches. Under EPR frameworks, producers become financially and operationally responsible for the entire lifecycle of their products, particularly the end-of-life management phase.

The OECD defines EPR as “an environmental policy approach in which a producer’s responsibility for a product is extended to the post-consumer stage of a product’s life cycle.” This responsibility manifests through several mechanisms: direct take-back programs, financial contributions to collective systems, modulated fees, reuse or recovery and recycling, or deposit-refund schemes.

For global businesses, EPR creates both challenges and opportunities. The challenge lies in navigating diverse regulatory frameworks across multiple jurisdictions, each with unique definitions of “producer,” varying fee structures, and different compliance deadlines. The opportunity emerges from EPR’s potential to drive innovation in sustainable product design and create competitive advantages for early adopters.

Why EPR Matters Now

Three converging factors make EPR compliance critical for modern businesses. First, regulatory expansion continues at an unprecedented pace—eight U.S. states now have packaging EPR laws, compared to zero just five years ago. Second, non-compliance penalties are substantial; California’s SB 54 includes fines of up to $50,000 per day for violations. Third, EPR requirements increasingly influence product design decisions, creating strategic implications beyond mere compliance.

The complexity multiplies for companies operating across borders. A single product might face different EPR obligations in California, France, and Ontario, each requiring separate compliance strategies, reporting systems, and financial contributions. This fragmentation has created a critical need for integrated compliance approaches that address multiple jurisdictions simultaneously.

The Global EPR Landscape: Current Status

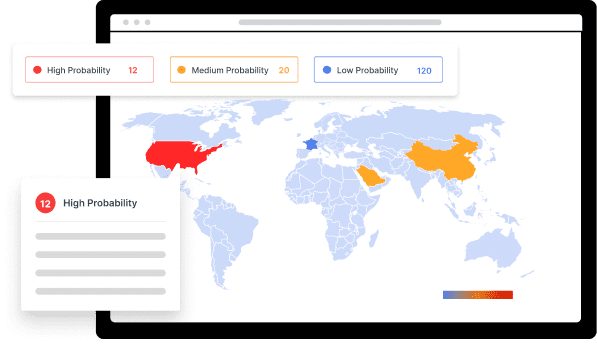

EPR implementation varies significantly across regions, reflecting different policy priorities, administrative capabilities, local infrastructure and economic structures. Understanding these regional approaches provides essential context for developing effective global compliance strategies.

European Union: The Mature Market

The EU leads globally in EPR implementation, with comprehensive frameworks covering packaging, electronics, batteries, and vehicles. The European approach emphasizes harmonization across member states while allowing flexibility in implementation details.

The EU’s Packaging and Packaging Waste Regulation (PPWR), which entered force on January 22, 2025, represents the most ambitious packaging EPR framework globally. The regulation mandates that all packaging must be recyclable and establishes specific recycling targets: 65% for all packaging waste by 2025, increasing to 70% by 2030.

European Electronics EPR, governed by the WEEE Directive, covers ten product categories and requires collection rates of at least 65% of electronics placed on the market over the previous three years. The directive’s scope includes everything from large household appliances to photovoltaic panels, creating comprehensive coverage across the electronics sector.

United States: Patchwork Evolution

The U.S. EPR landscape resembles a complex patchwork, with state-level initiatives driving policy development in the absence of federal frameworks. Seven states have enacted packaging EPR laws: Maine, Oregon, Colorado, California, New Jersey, Maryland, and Washington.

California’s landmark EPR law (SB 54) is back in motion after Governor Newsom restarted the rulemaking process in March 2025 to ensure the law’s environmental goals are met. The law establishes a $5 billion fund over the next 10 years for recycling infrastructure and mandates 65% recycling or composting rates for covered materials.

Oregon made headlines as the first U.S. state to activate its packaging EPR law under the Recycling Modernization Act (RMA). Over 1,700 producers submitted reports by the March 31, 2025 deadline, demonstrating the significant business impact of these new requirements.

Asia-Pacific: Emerging Leadership

Several Asia-Pacific countries are developing sophisticated EPR frameworks that may influence global standards. Japan’s EPR system, operational since 1998, demonstrates how EPR can function effectively in dense urban environments with limited space for waste management infrastructure.

South Korea’s comprehensive EPR system includes packaging, electronics, batteries, and tires. The Korean approach emphasizes ambitious recycling targets and substantial penalties for non-compliance, creating strong incentives for producer participation.

Packaging EPR: The Regulatory Leader

Packaging represents the most mature EPR category globally, with established programs operating across multiple jurisdictions. The rapid expansion of packaging EPR reflects growing concern about plastic waste and the recognition that traditional recycling approaches have proven insufficient.

U.S. State-by-State Analysis

Understanding the differences between state packaging EPR programs is crucial for developing effective compliance strategies. While all programs share common objectives, implementation details vary significantly.

California (SB 54):

- Coverage: Single-use packaging and food service ware

- Key Requirements: 25% reduction by 2032, 65% recycling rate

- Financial Mechanism: $5 billion infrastructure fund

- Implementation: Reporting deadline of November 15, 2025 for 2023 packaging and sales data remains unchanged

Oregon (SB 582):

- Coverage: Packaging materials and paper products

- Key Requirements: Minimum recycled content standards, design for recycling

- Financial Mechanism: Producer fees based on material type and recyclability

- Implementation: Fee payments due by July 1, 2025 or within 30 days since invoice issuance

Washington (SB 5284):

- Coverage: Packaging and paper products

- Key Requirements: Convenience standards, contamination reduction

- Financial Mechanism: Fee structure based on environmental impact

- Implementation: Passed in April 2025, with full implementation by 2030

The variation across states creates compliance challenges for national brands. A product distributed across all seven EPR states must meet different reporting requirements, pay fees to multiple systems, and comply with varying packaging design standards.

European Packaging EPR

The EU’s mature packaging EPR system provides insights into long-term program evolution. The PPWR builds upon decades of experience with packaging waste management, establishing ambitious targets that reflect technological and infrastructure improvements.

Key PPWR requirements include:

- Mandatory recycled content: 30% for plastic beverage bottles by 2030

- Reuse targets: 20% for beverage packaging by 2040

- Design restrictions: Limits on packaging-to-product ratios

- Extended scope: Coverage includes all packaging types, not just single-use

The regulation’s emphasis on packaging design requirements represents a significant evolution from traditional EPR approaches focused primarily on end-of-life management. Producers must now consider regulatory requirements during the design phase, creating opportunities for competitive advantage through sustainable packaging innovation.

Electronics EPR: Navigating WEEE Complexity

Electronics EPR has evolved from simple collection schemes to comprehensive frameworks addressing the full lifecycle of electronic products. The Waste Electrical and Electronic Equipment (WEEE) Directive in the EU and state-level programs across the U.S. create distinct compliance pathways that reflect different regulatory philosophies and infrastructure capabilities.

EU WEEE Directive: Comprehensive Coverage

The EU WEEE Directive covers ten categories of electrical and electronic equipment, from large household appliances to medical devices and monitoring instruments. The directive requires collection rates of at least 65% of the average weight of electrical and electronic equipment placed on the market in the three preceding years.

WEEE Categories and Requirements:

- Large household appliances: Refrigerators, washing machines, air conditioning units

- Small household appliances: Vacuum cleaners, irons, food processors

- IT and telecommunications equipment: Computers, printers, telephones

- Consumer equipment: Televisions, stereo equipment, video cameras

- Lighting equipment: Fluorescent lamps, LED products, discharge lamps

- Electrical and electronic tools: Drills, sewing machines, lawn mowers

- Toys and sports equipment: Electric trains, video game consoles

- Medical devices: Radiotherapy equipment, cardiology devices

- Monitoring and control instruments: Smoke detectors, thermostats

- Automatic dispensers: Hot drink machines, cold product dispensers

The directive places responsibility on producers to finance collection, treatment, and recovery operations. Producers must either establish individual take-back systems or join collective schemes operated by Producer Responsibility Organizations.

U.S. Electronics EPR Landscape

Over the past two decades, state lawmakers have demonstrated growing interest in extended producer responsibility, or EPR, enacting hundreds of laws across dozens of product categories. The early focus on products that were expensive to handle or hazardous like electronics has now extended to a broader set of waste.

Twenty-five U.S. states maintain electronics recycling programs, but approaches vary significantly. Some states operate manufacturer responsibility programs where individual producers manage their own collection and recycling. Others use collective systems similar to EU models.

State Program Models:

Manufacturer Responsibility States:

- California: Advance recycling fee collected at point of sale

- New York: Individual producer take-back requirements

- Texas: Manufacturer-specific collection and recycling obligations

Collective System States:

- Washington: Statewide program managed by industry organization

- Vermont: Producer responsibility organization coordinates activities

- Connecticut: Hybrid approach combining individual and collective elements

The fragmentation across states creates operational complexity for electronics manufacturers. A television sold nationwide must comply with different registration requirements, reporting formats, and fee structures in each EPR state.

Emerging Electronics Categories

The EU’s universal charger mandate, which took effect on 28 December 2024, requires USB-C as the standard charging port for a wide range of electronic devices, including mobile phones, tablets and cameras. This regulation aims to reduce electronic waste and improve consumer convenience.

EPR coverage continues expanding to include newer electronics categories. Solar panels, batteries from electric vehicles, and emerging technologies like smart home devices face increasing regulatory attention.

The EU recently expanded WEEE coverage to include photovoltaic panels, recognizing the growing volume of solar installations reaching end-of-life. This expansion demonstrates how EPR frameworks adapt to include emerging waste streams as they reach significant volumes.

Battery EPR: Power Source Responsibility

Battery EPR addresses one of the most hazardous waste streams in the modern economy. Batteries contain valuable materials like lithium, cobalt, and rare earth elements, making recovery economically attractive while preventing environmental contamination from improper disposal.

EU Battery Regulation: Setting Global Standards

The EU Battery Regulation, which entered force in August 2023, establishes the world’s most comprehensive battery EPR framework. Officially repealing the existing Battery Directive (2006/66/EC) as of 18 August 2025, the new regulation will establish one legal instrument with uniform application across all EU Member States.

Key Regulation Requirements:

- Collection targets: The collection rate for portable batteries must rise to 73% by 2030. For light vehicle batteries, targets are 51% by 2028 and 61% by 2031

- Recycling efficiency: specific targets for the recovery of cobalt, lead, lithium and nickel

- Material recovery: From 2030, batteries will need to contain a minimum recycled content of 12% for cobalt, 4% for lithium, 4% for nickel and 85% for lead

- Digital battery passport: Required for industrial (>2kWh), EV, and LMT batteries; must include carbon footprint, material origin, expected lifetime, and manufacturer details; accessible via QR code

- Due diligence: Originally scheduled for August 18, 2025, but postponed to August 18, 2027. Companies with a net turnover of less than EUR 150 million will be exempt

Critical 2025 Deadlines:

- Carbon Footprint Declaration: EV batteries must comply by 18 Feb 2025; rechargeable industrial batteries >2kWh by 18 Feb 2026

- August 18, 2025: Batteries must be labeled with the “separate collection” symbol

- Digital Battery Passport guidelines: The final operational guidelines for implementing the passport will be published by 18 August 2025

The regulation’s scope includes portable batteries, industrial batteries, automotive batteries, and electric vehicle batteries. Each category faces specific requirements tailored to typical use patterns and end-of-life management challenges.

U.S. Battery EPR Programs

The United States approaches battery EPR through a combination of federal universal waste regulations and state-specific programs. Connecticut and Nebraska enacted battery EPR laws in 2025.

Federal Framework: The Universal Waste Rule provides streamlined hazardous waste management requirements for batteries, but doesn’t establish EPR obligations. Producers voluntarily participate in collection programs operated by organizations like Call2Recycle.

State Programs:

- California: Battery recycling fee on rechargeable batteries

- New York: Producer take-back requirements for rechargeable batteries

- Vermont: Comprehensive battery stewardship program covering all battery types

- Connecticut: Passed HB 5019 An Act Establishing Producer Responsibility for Consumer Batteries in June 2025

- Nebraska: Enacted LB36 the Safe Battery Collection and Recycling Act in May 2025

The voluntary nature of most U.S. battery EPR creates market-driven solutions but may not achieve the collection rates seen in mandatory European programs.

Electric Vehicle Battery Challenges

Electric vehicle batteries present unique EPR challenges due to their size, value, and technological complexity. A typical EV battery pack weighs 500-1,000 pounds and contains materials worth thousands of dollars when properly recovered.

Battery passports will be key to enabling a second-hand market for batteries that are appropriate for reuse. Alongside the labeling of batteries, this may lead to improvements in Li-ion battery recycling by simplifying the separation process by sorting batteries by chemistry.

Textiles and Furniture: The Next Frontier

Textiles and furniture represent emerging EPR categories gaining regulatory attention across multiple jurisdictions. The European Union leads development in these areas, with other regions monitoring European approaches for potential adoption.

European Textile EPR Development

The WFD requires all EU Member States to establish separate textile waste collection systems by January 1, 2025, requiring municipalities to separate textiles from general waste. However, there is no exact deadline for implementing EPR systems, and it will depend on the final adoption date of the proposed amendment.

The EU generates 12.6 million tonnes of textile waste per year. Every year, clothing and footwear alone account for 12 kg of waste per person in the EU. The EU aims to increase the percentage of textile waste collected for re-use or recycling, which is currently only 22%.

Proposed Textile EPR Elements:

- Expansion of EPR to Textiles: Fashion brands must finance the collection, sorting, reuse, and recycling of post-consumer textiles, shoes, and household linen

- Mandatory separate collection of textile waste

- Targets for reuse and recycling of textile materials

- Design requirements promoting durability and recyclability

- Digital product passports for traceability

Current National Implementation:

France was the pioneer in implementing Extended Producer Responsibility (EPR) for textiles, introducing the regulation in 2008. By 2022, the target was to collect 50% of all textiles put on the market, with 95% of collected textiles being reused or recycled.

The Netherlands has been at the forefront of textile EPR implementation. Since July 2023, the Dutch EPR Decree has required producers to achieve a minimum of 50% recycling and 20% reuse of textiles by 2025, with targets increasing to 75% recycling and 25% reuse by 2030.

Spain is set to implement its textile EPR obligations in 2025. In anticipation, major retailers, including Inditex (Zara), H&M, Decathlon, Ikea, and Primark, launched a voluntary pilot scheme in April 2025 to collect discarded clothes.

Furniture EPR Pilot Programs

Furniture EPR remains in early development, with limited pilot programs providing implementation experience. The Netherlands operates a furniture EPR program focusing on office furniture, while several EU member states consider comprehensive furniture coverage.

Furniture EPR faces unique challenges due to product diversity, durability, and consumer behavior patterns. Unlike packaging or electronics, furniture products may remain in use for decades, creating complexities for producer responsibility tracking and fee collection.

Producer Responsibility Organizations: Your Compliance Partners

Producer Responsibility Organizations serve as the operational backbone of collective EPR systems. These organizations manage day-to-day compliance activities, allowing individual producers to meet regulatory obligations without developing independent infrastructure.

PRO Functions and Services

PROs typically provide comprehensive compliance services including regulatory reporting, fee collection and distribution, compliance tracking, stakeholder engagement, and infrastructure development support.

Core PRO Services:

- Regulatory compliance management

- Collection and recycling infrastructure coordination

- Producer registration and reporting

- Fee calculation and collection

- Performance monitoring and reporting

- Technical assistance and guidance

The effectiveness of PRO operations significantly impacts overall program success. Well-managed PROs achieve higher collection rates, lower administrative costs, and greater producer satisfaction compared to fragmented individual compliance approaches.

Selecting the Right PRO

Producer selection of PROs involves evaluating operational capabilities, cost structures, service quality, and strategic alignment. Key evaluation criteria include coverage area, material expertise, fee transparency, performance track record, and service responsiveness.

PRO Evaluation Framework:

Responsive customer service and technical support

Geographic coverage matching distribution footprint

Experience with relevant product categories

Transparent fee structure and cost allocation

Strong collection and recycling partnerships

Robust data management and reporting capabilities

Fee Structures and Financial Planning

EPR fees vary significantly across programs, reflecting different cost recovery models, infrastructure requirements, and policy objectives. Understanding fee structures enables accurate compliance budgeting and strategic planning.

Fee Calculation Methodologies

Most EPR programs use weight-based fee structures, charging producers based on the quantity of material placed on the market. However, some programs incorporate additional factors like material type, recyclability, and environmental impact.

Common Fee Structure Models:

- Weight-based: Fees calculated per unit weight of material

- Unit-based: Fixed fees per product unit regardless of weight

- Value-based: Fees calculated as percentage of product value

- Modulated: Variable fees reflecting environmental impact

- Hybrid: Combination of multiple calculation methods

California’s packaging EPR program will implement modulated fees that reward producers for using more recyclable materials and penalize those using problematic materials. This approach creates financial incentives for sustainable design decisions.

Budget Planning Considerations

Effective EPR budget planning requires accurate forecasting of covered material volumes, fee rate projections, administrative costs, and potential penalty exposure. Companies should develop multi-year budget models that account for regulatory changes and program evolution.

Budget Planning Elements:

- Risk contingencies for regulatory changes

- Material volume forecasting by jurisdiction

- Fee rate escalation assumptions

- Administrative and compliance costs

- Technology and system development investments

Emerging Trends and Future Outlook

EPR continues evolving rapidly, with new product categories, geographic coverage, and regulatory approaches constantly developing. Understanding emerging trends enables proactive compliance planning and strategic positioning.

Digital Infrastructure Integration

Digital technologies increasingly support EPR implementation through product tracking, supply chain transparency, and automated reporting. The EU’s digital product passport requirements for batteries demonstrate how technology integration enhances program effectiveness.

Digital Trend Areas:

- Real-time compliance monitoring dashboards

- Blockchain-based traceability systems

- AI-powered waste sorting and identification

- Digital product passports and QR codes

- Automated data collection and reporting

Circular Economy Integration

EPR programs increasingly integrate with broader circular economy initiatives, emphasizing design for circularity, material recovery, and waste prevention. This evolution expands producer responsibilities beyond end-of-life management to include upstream design decisions.

Global Harmonization Efforts

International organizations work toward greater EPR program harmonization, potentially reducing compliance complexity for global businesses. The OECD and UN Environment Programme lead efforts to establish common principles and best practices.

Building Your Compliance Strategy

Successful EPR compliance requires systematic planning that integrates regulatory requirements with business operations. The most effective strategies anticipate regulatory evolution while building flexible systems that adapt to changing requirements.

Compliance Planning Framework

Step 1: Regulatory Mapping Identify all current and planned EPR requirements affecting your products and markets. This assessment should cover material types, producer definitions, compliance deadlines, and fee structures across all relevant jurisdictions.

Step 2: Gap Analysis Compare current capabilities against regulatory requirements to identify compliance gaps. Consider data collection systems, reporting processes, fee payment mechanisms, and organizational responsibilities.

Step 3: System Development Implement systems and processes that address identified gaps while building flexibility for future requirements. Focus on data management, supplier collaboration, and cross-functional coordination.

Step 4: Implementation and Monitoring Execute compliance activities while continuously monitoring regulatory developments and program performance. Regular assessment ensures ongoing compliance and identifies optimization opportunities.

Success Metrics and KPIs

Effective EPR compliance programs establish clear metrics for measuring success and identifying improvement opportunities. Key performance indicators should address regulatory compliance, cost management, and strategic objectives.

Core Compliance Metrics:

- Regulatory compliance rate across all jurisdictions

- Fee payment accuracy and timeliness

- Reporting quality and completeness

- Audit performance and corrective action implementation

- Stakeholder satisfaction scores

The future of EPR promises continued expansion and evolution. Businesses that develop robust compliance capabilities while maintaining strategic flexibility will be best positioned to thrive in this changing regulatory landscape. Success requires viewing EPR not merely as a compliance obligation, but as an opportunity to drive innovation, reduce costs, and build competitive advantages through sustainable business practices.

Frequently Asked Questions

- What is Extended Producer Responsibility (EPR)? Extended Producer Responsibility is an environmental policy approach that makes producers responsible for the entire lifecycle of their products, particularly end-of-life management including collection, recycling, and proper disposal.

- Which products are covered by EPR regulations? EPR coverage varies by jurisdiction but commonly includes packaging, electronics, batteries, vehicles, and increasingly textiles and furniture. Each region may define covered products differently within these categories.

- Do I need to comply with EPR if I only sell online? Yes, EPR obligations typically apply regardless of sales channel. Online sellers are generally considered producers if they place covered products on the market in EPR jurisdictions, though specific definitions vary by program.

- How do I determine which EPR programs apply to my business? EPR obligations depend on where you place products on the market, not where your business is located. You must comply with EPR requirements in each jurisdiction where you sell covered products, whether directly or through distributors.

- What are the penalties for EPR non-compliance? Penalties vary significantly by jurisdiction and can include fines, product bans, and criminal liability. California’s packaging EPR includes fines up to $50,000 per day for violations, while EU programs may impose substantial financial penalties and market access restrictions.

- Can I join multiple Producer Responsibility Organizations? Yes, many producers work with different PROs in different jurisdictions or for different product categories. However, ensure you don’t double-pay for the same obligations and maintain clear records of your compliance activities across all programs.

- How do EPR fees compare to traditional waste management costs? EPR fees are typically lower than comprehensive waste management programs because they leverage economies of scale and focus on material recovery value. However, total compliance costs including administrative overhead may exceed simple disposal costs.

- When should I start preparing for upcoming EPR requirements? Begin EPR planning 18-24 months before program implementation. This timeline allows for system development, data collection processes, supplier collaboration, and staff training while avoiding rushed compliance efforts.

- What are the latest developments in EU textile EPR? A provisional agreement on the targeted revision of the Waste Framework Directive was reached in February 2025. Under this, harmonised rules on the EPR scheme for textile industries and fashion brands have been established, requiring them to pay a fee to help finance the collection and treatment of waste.

- How will the EU Battery Regulation’s due diligence requirements change? The original application date of 18 August 2025 is now postponed to 18 August 2027. Companies with a net turnover of less than EUR 150 million will be exempt from the battery due diligence obligations.

Stay Ahead Of Regulatory Changes in EPR Regulations

Want to stay ahead of regulatory developments in EPR Regulations?

Accelerate your ability to achieve, maintain & expand market access for all products in global markets with C2P – your key to unlocking market access, trusted by more than 300 of the world’s leading brands.

C2P is an enterprise SaaS platform providing everything you need in one place to achieve your business objectives by proving compliance in over 195 countries.

C2P is purpose-built to be tailored to your specific needs with comprehensive capabilities that enable enterprise-wide management of regulations, standards, requirements and evidence.

Add-on packages help accelerate market access through use-case-specific solutions, global regulatory content, a global team of subject matter experts and professional services.

- Accelerate time-to-market for products

- Reduce non-compliance risks that impact your ability to meet business goals and cause reputational damage

- Enable business continuity by digitizing your compliance process and building corporate memory

- Improve efficiency and enable your team to focus on business critical initiatives rather than manual tasks

- Save time with access to Compliance & Risks’ extensive Knowledge Partner network

Simplify Corporate Sustainability Compliance

Six months of research, done in 60 seconds. Cut through ESG chaos and act with clarity. Try C&R Sustainability Free.