The Product Compliance Automation Blueprint: Evidence Collection Across Design, Production, and Supply Chain

THIS BLOG WAS WRITTEN BY THE COMPLIANCE & RISKS MARKETING TEAM TO INFORM AND ENGAGE. HOWEVER, COMPLEX REGULATORY QUESTIONS REQUIRE SPECIALIST KNOWLEDGE. TO GET ACCURATE, EXPERT ANSWERS, PLEASE CLICK “ASK AN EXPERT.”

Approaching audits triggers intensive evidence retrieval efforts. Teams search shared drives for historical supplier RoHS declarations. Engineers attempt to identify which project management tickets correspond to design changes addressing specific safety standards. Quality teams scan extensive batch records seeking required signatures and approvals.

This represents controlled chaos with substantial costs.

The average cost of non-compliance reaches $9.4 million annually. In contrast, maintaining compliance costs approximately $3.5 million. This nearly $6 million gap represents the price of inefficiency, risk, and manual, resource-intensive processes.

Organizations seeking automation face a critical distinction most platforms overlook: automating IT security compliance for frameworks like SOC 2 differs fundamentally from automating product compliance.

Product compliance operates in the physical world of design laboratories, factory floors, and global supply chains. Evidence is not always structured log files – it includes material certificates in PDF format, quality inspection photographs, or handwritten maintenance records.

This blueprint guides selection of appropriate automation built for entire product lifecycle complexities.

Table of Contents

- Decoding the Product Lifecycle: Where Compliance Evidence Actually Lives

- The Technical Leap: Why Your Old Automation Fails

- A Practical Framework for Choosing Your Automation Platform

- The Future is Here: AI-Assisted Compliance and Human Expertise

- Key Takeaways: Automated Product Compliance Essentials

- Frequently Asked Questions

- Transform Evidence Collection into Strategic Advantage

Decoding the Product Lifecycle: Where Compliance Evidence Actually Lives

Most GRC platforms originate from IT-centric perspectives. They excel at extracting data from AWS, Okta, and GitHub. However, product compliance narratives begin before initial code development and extend far beyond cloud infrastructure. Effective product compliance automation platforms must operate within actual work environments.

Design & Engineering

Compliance originates here. Every material choice, component selection, and design specification represents a compliance decision. Evidence generation occurs constantly, often embedded within engineering tools.

Evidence includes Failure Mode and Effects Analyses, design schematics, Bills of Materials, risk assessments, and software version histories from project management systems. The automation challenge involves automatically tagging these documents and linking them to specific clauses in standards such as IEC 60601 for medical devices. The objective is creating live, traceable links between design choices and the requirements they satisfy.

Production & Quality

Once products reach factory floors, evidence trails expand significantly. This is where physical products take shape, and every step requires documentation proving adherence to specifications, safety protocols, and consistency standards.

Evidence includes batch records, Certificates of Analysis for raw materials, quality inspection reports with images, equipment calibration logs, and employee training records. The automation challenge involves ingesting and classifying these varied formats. Systems must extract pass/fail results from PDF quality reports and read lot numbers from scanned Certificates of Analysis. This extends far beyond typical IT compliance tool capabilities.

Supply Chain & Sourcing

This is where most compliance programs encounter the greatest challenges. Supply chains represent global, multi-tiered networks of partners, each maintaining distinct documentation systems. Obtaining evidence from suppliers constitutes full-time work.

Evidence includes supplier declarations of conformity, material safety data sheets, conflict minerals reports, and social audit results. These often arrive as low-quality scans, emails, or password-protected portal downloads. The automation challenge involves creating frictionless supplier evidence submission mechanisms and implementing systems capable of automatic validation. Systems must verify that declarations correspond to correct part numbers, check expiration status, and confirm coverage of specific regulations such as REACH or Prop 65.

The Technical Leap: Why Your Old Automation Fails

Product compliance evidence differs fundamentally from IT compliance data. Many automation platforms struggle with it due to the underlying technology employed. They apply legacy tools to contemporary problems.

The Fragile World of Rule-Based Automation

Most automation is simply rule-based. Think of mail-sorting systems: “If the document title contains ‘RoHS,’ place it in the ‘RoHS’ folder.” This functions perfectly until suppliers send files named “EU_Material_Spec_2024.pdf” containing RoHS data on page three.

The rule fails. Evidence is missed. Audits fail.

Rule-based systems are fast but extremely brittle. They lack contextual understanding and require constant maintenance as regulations, suppliers, and document formats evolve. They cannot accommodate real-world variance.

The Unstructured Data Nightmare: OCR Isn’t the Answer

The next logical step involves Optical Character Recognition. Converting scanned documents to searchable text sounds effective in theory.

However, legacy OCR technology proves insufficient for compliance demands. It often fails catastrophically on the most critical documents. Complex layouts cannot be interpreted correctly in dense Certificate of Analysis tables. Poor quality scans garble text from faxed supplier declarations. Handwritten notes including technician signatures and dates on calibration logs are completely missed.

OCR extracts characters from pages without extracting meaning. It cannot distinguish between dates in headers and expiration dates in document bodies. It does not recognize that “Lead (Pb): < 0.1%” represents the critical compliance evidence required.

The Real Solution: Intelligent Document Processing

Intelligent Document Processing represents the necessary technical advancement. Unlike OCR, IDP uses AI and machine learning models to understand documents as human experts would.

OCR sees jumbled letters and numbers. IDP understands that “This is a Certificate of Analysis for part number X, tested on date Y, and the test result for substance Z is ‘Pass’.”

IDP can be trained to locate and extract specific data points regardless of document location or format variations. It can normalize data, converting all dates to standard formats, and validate against requirements. This resolves unstructured data challenges and creates resilient, audit-ready compliance programs.

A Practical Framework for Choosing Your Automation Platform

When comparing solutions, flashy dashboards and extensive feature lists can distract from fundamental requirements. Organizations need to focus on what actually matters for product compliance. Use these three evaluation lenses for any potential platform.

Metric #1: True ROI Beyond Simple Time Savings

Automation saves time. Some reports show 70% reduction in manual documentation time and 85% faster audit preparation. This represents a valuable starting point.

However, the genuine ROI is risk reduction. Frame investments against that $9.4 million non-compliance cost. What is the cost of product recalls? Shipments stopped at borders? Loss of market access? The appropriate platform is not a cost center but insurance against catastrophic failure. Powerful ROI represents one of the most critical benefits of regulatory compliance management systems.

Metric #2: The Integration Audit

Every vendor presents slides with dozens of logos – AWS, Azure, Jira, Slack. These represent baseline expectations.

The critical question is whether they can integrate with systems running product lifecycles. Can they pull Bills of Materials and design specifications directly from Product Lifecycle Management systems like Siemens Teamcenter or PTC Windchill? Can they connect to Quality Management Systems to automatically gather CAPAs, non-conformance reports, and training records? Can they link compliance evidence to specific part numbers, suppliers, and purchase orders in Enterprise Resource Planning systems like SAP or Oracle?

Integration with PLM systems proves infinitely more valuable for product compliance than Slack integration. Organizations should demand depth where it matters rather than being impressed by quantity.

Metric #3: The Auditor Trust Factor

Ultimately, all evidence serves auditors – whether internal, customer, or regulatory. They require data trustworthiness. Platforms must be built on “Processing Integrity” principles.

This means every automatically collected piece of evidence must have non-modifiable, fully traceable audit trails. Where did it originate? When was it collected? Has it been altered?

Auditors need to see that evidence represents pristine, untouchable records. Systems allowing manual edits or maintaining unclear chains of custody will be rejected. The goal is presenting complete, defensible compliance narratives where data speaks for itself.

The Future is Here: AI-Assisted Compliance and Human Expertise

Evidence collection represents only the beginning. The next frontier uses AI not only to gather information but also to synthesize and generate complex documentation modern regulations require.

Beyond Collection: AI for Technical File Generation

Regulations like the EU AI Act and Medical Device Regulation require massive, constantly evolving technical files. These documents can span thousands of pages, linking requirements to design evidence, risk assessments, and post-market surveillance data.

Emerging AI is now being employed to automate these processes. By understanding relationships between regulations and collected evidence, AI can draft initial technical file sections, identify gaps where evidence is missing, and automatically update files when underlying evidence such as component specifications changes.

This moves beyond simple data collection into content synthesis, transforming compliance burdens into dynamic, manageable assets.

Keeping Humans in the Loop

This is not about replacing compliance professionals but empowering them. The most powerful model is “human-in-the-loop,” where AI handles heavy lifting of gathering, classifying, and even drafting, but human experts provide final validation and strategic oversight.

Automation handles 80% of tedious, repetitive work, freeing teams to focus on the 20% requiring critical thinking: interpreting ambiguous areas in new regulations, negotiating with suppliers on material changes, and making strategic decisions about risk. The goal is augmenting experts, not replacing them.

Key Takeaways: Automated Product Compliance Essentials

What is automated product compliance evidence collection? It is the process of using technology to automatically gather, classify, and link documentation from across the product lifecycle – including design, production, and the supply chain – to prove adherence to specific regulations and standards.

Why is OCR not enough for compliance documents? Standard OCR only converts images to text without understanding context. Intelligent Document Processing (IDP) is required to accurately extract specific data points from complex, unstructured documents like certificates of analysis, supplier declarations, and quality reports.

How does product compliance automation differ from IT GRC automation? Product compliance automation must integrate with PLM, QMS, and ERP systems and handle messy, unstructured evidence from the physical world. IT GRC automation focuses primarily on structured data from cloud infrastructure and software development tools.

What is the ROI of product compliance automation? Beyond time savings of 70% in manual documentation, the true ROI is risk reduction against the $9.4 million average annual cost of non-compliance, preventing product recalls, border shipment delays, and market access loss.

Frequently Asked Questions

- Q: How does an automated system keep up with constant global regulatory changes?

Leading platforms combine automation with human expertise. Global teams of subject matter experts analyze new and changing regulations, then translate them into machine-readable rules and data structures that power automation engines, ensuring evidence collection remains aligned with the latest requirements. - Q: Our evidence is stored in multiple legacy systems. How difficult is implementation?

Modern platforms are built for this reality. Implementation typically involves using combinations of pre-built connectors for common systems like PLM and ERP, APIs for custom integrations, and IDP technology to process documents from systems that cannot be directly connected, such as automated email inbox monitoring or shared drive extraction. - Q: How can we trust our sensitive product data is secure in a cloud-based platform?

Organizations should seek platforms with robust security credentials like ISO 27001 certification and SOC 2 Type II reports. Data should be encrypted both in transit and at rest, with granular user permissions ensuring employees and suppliers only access information relevant to their roles. - Q: What happens when a supplier submits an incomplete or incorrect document?

Smart systems should automatically flag issues. Platforms can be configured with validation rules such as “document must contain a valid part number” or “expiration date must be in the future.” They can then automatically notify suppliers of specific issues and request corrected documents, closing the loop without manual intervention.

Transform Evidence Collection into Strategic Advantage

The chaos of manual evidence collection is not merely an inconvenience but a significant business risk. However, adopting generic automation is not the solution. Organizations require platforms that understand product development language, comprehend factory floor complexity, and can navigate global supply chain intricacies.

By focusing on deep lifecycle integration, embracing AI-powered document processing, and demanding auditor-proof integrity, organizations can move beyond simply managing compliance to building genuine competitive advantages.

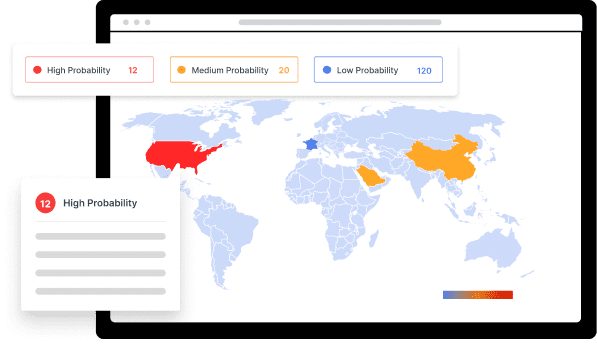

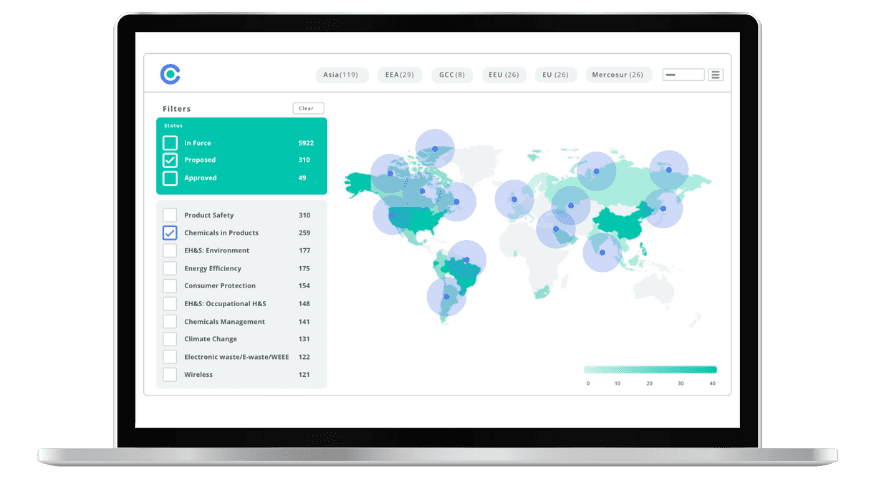

When organizations integrate regulations management, requirements management, and evidence management into centralized platforms tracking over 100,000 global regulations and standards across 195 countries, they establish more than operational efficiency. They create the foundation for transforming evidence collection from compliance burden into strategic capability that accelerates time-to-market, reduces operational disruption, and positions regulatory excellence as a differentiator in competitive markets.

Experience the Future of ESG Compliance

The Compliance & Risks Sustainability Platform is available now with a 30-day free trial. Experience firsthand how AI-driven, human-verified intelligence transforms regulatory complexity into strategic clarity.

👉 Start your free trial today and see how your team can lead the future of ESG compliance.

The future of compliance is predictive, verifiable, and strategic. The only question is: Will you be leading it, or catching up to it?

Simplify Corporate Sustainability Compliance

Six months of research, done in 60 seconds. Cut through ESG chaos and act with clarity. Try C&R Sustainability Free.