The Compliance-by-Design Playbook: Your Strategy to Stop Fires Before They Start

THIS BLOG WAS WRITTEN BY THE COMPLIANCE & RISKS MARKETING TEAM TO INFORM AND ENGAGE. HOWEVER, COMPLEX REGULATORY QUESTIONS REQUIRE SPECIALIST KNOWLEDGE. TO GET ACCURATE, EXPERT ANSWERS, PLEASE CLICK “ASK AN EXPERT.”

Let’s be honest. There’s that moment every product leader dreads. The product launch is weeks away, the culmination of thousands of engineering hours and millions in investment. Then, the email lands. The compliance audit found a gap. A requirement from an obscure sub-clause of a new regulation wasn’t documented in the design verification stage.

Suddenly, everything grinds to a halt. Teams scramble, pulling engineers off the next project to dig through old files, trying to reverse-engineer proof of compliance. The launch date is in jeopardy. And for what? A missing document.

If this sounds familiar, you’re not alone. The reality is, for most companies, documentation is an afterthought – a painful, retrospective exercise done under duress. But what if it wasn’t? What if your documentation wasn’t just a record of what you did, but an active guide that ensures you build a compliant product from the very first sketch? That’s the core promise of a Compliance-by-Design (CbD) documentation strategy. This isn’t about creating more paperwork; it’s about creating a smarter, more resilient product development lifecycle.

This playbook will walk you through the strategic and tactical shifts required to embed compliance documentation into the DNA of your design process. We’ll move from theory to action, covering everything from PLM integration to advanced evidence modeling with digital twins.

Table of Contents

- The Real Cost of “We’ll Document it Later”

- What is Compliance-by-Design Documentation, Really?

- Systemic Integration: Your PLM as the First Line of Defense

- The Unsung Hero: A Playbook for Your Requirements Traceability Matrix (RTM)

- Future-Proofing Your Compliance: Advanced Evidence Modeling

- From Process to Culture: Securing Executive Buy-In

- Key Takeaways: Your CbD Documentation Cheat Sheet

- Frequently Asked Questions

The Real Cost of “We’ll Document it Later”

The “document it later” approach isn’t just inefficient; it’s a massive, unquantified business risk. It transforms compliance from a predictable process into a high-stakes gamble. And the house usually wins.

Think about it this way: the traditional model treats compliance documentation as a final exam you cram for. The CbD model, on the other hand, treats it like open-book homework you do a little bit of every day. Which approach do you think leads to better results?

The data is pretty clear on this.

- A staggering 60% of compliance failures are directly caused by poor or inadequate documentation. It’s not that the product was non-compliant; it’s that the company couldn’t prove it was compliant.

- This isn’t just an internal problem. Regulators are laser-focused on it. In 2022, over 60% of FDA warning letters cited documentation inadequacies as a key finding.

- The financial fallout is severe. One pharmaceutical company was hit with a $5 million fine specifically for documentation lapses. This doesn’t even account for the cost of remediation, lost sales from delayed launches, and damage to brand reputation.

But the cost isn’t just in fines. It’s in the operational drag. The frantic, last-minute scramble for documentation consumes immense resources. Manual compliance processes can devour up to 30% of a marketing or operational budget due to the labor-intensive nature of chasing down information and resolving bottlenecks.

This is the hidden tax of reactive compliance. Compliance-by-Design isn’t an added cost; it’s the elimination of this tax.

What is Compliance-by-Design Documentation, Really?

CbD documentation is a fundamental mindset shift. It reframes documentation from a static record created at the end of a process to a dynamic, integral part of the process. It’s not about the final PDF; it’s about the documented, auditable trail of decisions made along the way.

To make this tangible, we can break it down into four core pillars.

Pillar 1: Early Integration

This means compliance requirements are treated just like any other functional requirement from day one. They are identified, logged, and assigned ownership right alongside specifications for performance, materials, and usability. The documentation process begins when the first design input is defined, not when the first prototype is built.

Pillar 2: Traceability by Default

Every single regulatory requirement is linked directly to a design input, which is then linked to a design output, which is finally linked to a verification and validation (V&V) test case. This creates an unbroken “golden thread” that an auditor can follow from the regulation itself all the way to the test report that proves you met it.

Pillar 3: Living Risk Assessments

Instead of a one-and-done FMEA (Failure Mode and Effects Analysis) or risk assessment that gets filed away, the risk document is a living artifact. It’s tied directly to design components within your PLM system. When a design choice is made, its impact on the risk profile is documented in real-time.

Pillar 4: Automated Evidence Generation

The goal is to move away from manually assembling a design history file or technical file. A mature CbD system automatically collates evidence as it’s created. A passed test, a signed-off design review, a validated material spec – each of these events generates an auditable piece of evidence that is automatically linked to the relevant requirements.

Systemic Integration: Your PLM as the First Line of Defense

Your Product Lifecycle Management (PLM) or Quality Management System (QMS) is the natural home for a CbD documentation strategy. It’s the single source of truth for your product data, so it should also be the single source of truth for your compliance data.

But this requires more than just storing documents in a new folder. It means actively configuring your PLM to enforce compliance. Here’s how:

- Mandatory Compliance Checkpoints at Design Gates: Configure your stage-gate process so that a design cannot advance from one stage (e.g., Concept to Design) to the next without the required compliance documentation being completed and approved. For example, a design can’t be released to prototyping until the initial risk assessment is attached to the CAD model and the regulatory requirements have been mapped.

- Link Requirements to Components: Use your PLM’s capabilities to link specific regulatory requirements directly to the parts or sub-assemblies they affect. A RoHS requirement, for example, should be linked to every electronic component, bill of materials (BOM), and supplier declaration. This makes impact analysis for regulatory changes almost instantaneous.

- Automated Change Control Workflows: When a design changes, the documentation must change with it. A robust CbD process uses automated workflows. If an engineer changes a material specification, the system should automatically flag the change and trigger a review to ensure compliance documentation (like a new supplier declaration) is updated. This prevents the dreaded disconnect where the product on the factory floor no longer matches its documentation.

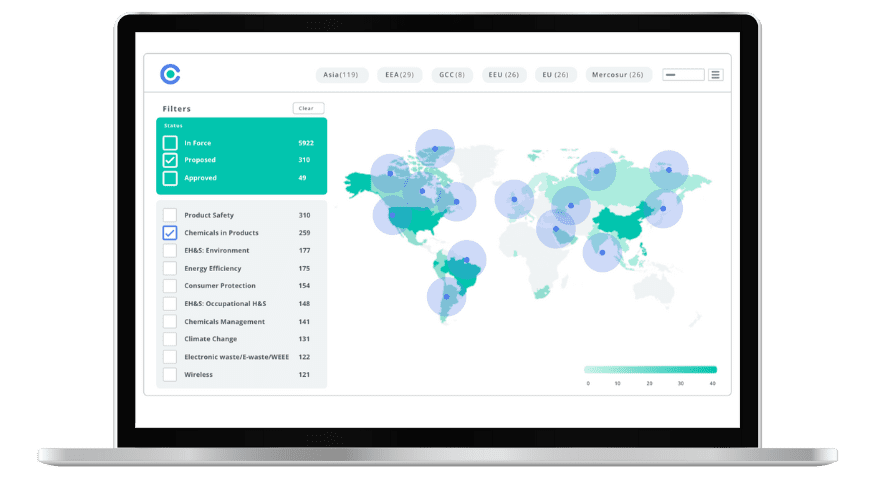

Effective integration turns your PLM from a passive library into an active compliance engine. It’s no longer just about version control for CAD files; it’s about version control for your entire compliance posture, powered by a system for global regulatory tracking that keeps you ahead of changes.

The Unsung Hero: A Playbook for Your Requirements Traceability Matrix (RTM)

If the PLM is the engine, the Requirements Traceability Matrix (RTM) is the GPS. It is arguably the single most important document in a CbD framework. It’s the master key that connects the “what” (the regulations) to the “how” (your design and testing).

A weak RTM is a list. A strong RTM is a map.

Here’s how to build a strong one:

The Flow: The RTM creates a bi-directional chain of evidence. An auditor should be able to pick any link in the chain and trace it forwards and backwards.

Regulatory Source -> User Need -> Design Input -> Design Output -> V&V Test Case -> Test Result

- Regulatory Source: The specific regulation, standard, and clause number. (e.g., IEC 60601-1, Clause 7.1.1)

- User Need: A plain-language interpretation of what the regulation means for the user. (e.g., “The device must be safe to touch during normal operation.”)

- Design Input: The specific engineering requirement that will satisfy the user need. (e.g., “The surface temperature of the enclosure shall not exceed 41°C.”)

- Design Output: The drawing, specification, or component that implements the design input. (e.g., Drawing #A-12345, Material Spec #MS-678)

- Verification/Validation (V&V) Test Case: The specific test protocol that will prove the design output meets the design input. (e.g., Test Protocol #TP-V-001: Surface Temperature Measurement)

- Test Result: The link to the signed test report showing the pass/fail status. (e.g., Report #TR-V-001, Status: Passed)

Building Your RTM:

A simple spreadsheet can work, but a database-driven approach within your PLM or a dedicated requirements management tool is far more powerful. Your RTM should be a living dashboard, not a static file.

| Req ID | Regulatory Source | Design Input | Design Output (Link) | V&V Protocol (Link) | V&V Status | Owner |

|---|---|---|---|---|---|---|

| ELEC-001 | IEC 60601-1, Cl. 8.1 | Device must have 2 forms of patient protection. | Schematic #S-54321 | Test Report #TR-E-005 | PASS | J. Smith |

| MECH-004 | ISO 10993-5 | Patient-contacting materials must be non-cytotoxic. | Material Spec #MS-987 | Biocompatibility Report #BR-012 | PASS | A. Lee |

This structure makes audits incredibly simple. An auditor asks, “How do you comply with IEC 60601-1, Clause 8.1?” You filter the RTM for that source and show them the entire evidence chain in seconds. This turns a stressful, multi-day audit into a confident, hour-long review and provides the foundation for clear compliance action plans.

Future-Proofing Your Compliance: Advanced Evidence Modeling

Once you have the fundamentals of PLM integration and a robust RTM in place, you can move to more advanced, proactive strategies that create a true competitive advantage. This is about moving from periodic evidence collection to continuous compliance assurance.

Leveraging Digital Twins for Continuous Compliance

A digital twin is a high-fidelity virtual model of a physical product. In the context of compliance, its power is revolutionary. Instead of relying solely on physical tests at the end of the design cycle, you can use a digital twin to model and simulate compliance scenarios continuously during development.

Think about it:

- EMC Compliance: Instead of waiting for expensive and time-consuming chamber testing, you can simulate electromagnetic interference based on the PCB layout and enclosure design in the digital twin. The simulation results become early-stage evidence of compliance consideration.

- Thermal Safety: For a medical device, you can simulate the heat generated by components under various usage conditions to ensure surface temperatures remain within the limits defined by IEC 60601. The simulation report is your documented proof.

- Structural Integrity: For industrial equipment, you can run virtual stress tests based on regulatory load requirements (e.g., ANSI standards), documenting that your design meets safety factors long before any metal is cut.

The digital twin doesn’t replace final validation testing, but it provides a rich, data-driven layer of evidence that demonstrates compliance was considered at every step. This alignment with regulatory expectations is a core tenet of modern solutions for compliance.

Integrating FMEA into the Design Loop

Too often, risk assessments like FMEA are done in a spreadsheet, separate from the actual design environment. A CbD approach integrates risk directly into the PLM.

When an engineer models a part in CAD, they can link it directly to the FMEA.

This creates a dynamic link between design and risk. If a critical component is modified, the system can automatically flag the associated risks for reassessment. This ensures your risk documentation is never out of sync with your product design, demonstrating a proactive, risk-based approach that regulators love to see.

From Process to Culture: Securing Executive Buy-In

A Compliance-by-Design strategy is not just an engineering initiative; it’s a cultural transformation. It requires buy-in from the top down, shifting the perception of compliance from a cost center to a strategic function that protects revenue and enhances brand value.

Here’s how you make the case:

- Speak in the Language of Risk: Frame the conversation around risk mitigation, not just compliance. Use the data: “A 60% failure rate due to documentation represents a significant risk to our launch timelines and revenue projections. A $5 million fine is a material event.”

- Focus on Speed-to-Market: CbD eliminates the last-minute compliance scrambles that delay product launches. By building the evidence as you go, you compress the final regulatory submission timeline, getting your product to market faster than competitors who are still chasing signatures.

- Highlight Executive Accountability: With regulations like the EU’s proposed Corporate Sustainability Due Diligence Directive (CSDDD) and frameworks like SEAR (Senior Executive Accountability Regime), executives are being held personally responsible for compliance failures. A CbD framework is a powerful tool for demonstrating due diligence and protecting leadership.

This isn’t about blaming individuals; it’s about building a system that makes doing the right thing the easiest thing to do. It fosters a culture where everyone, from the junior engineer to the CTO, understands their role in building a safe, effective, and compliant product.

Key Takeaways: Your CbD Documentation Cheat Sheet

What is Compliance-by-Design Documentation?

It’s a strategy that integrates documentation creation into the early stages of product design, treating compliance requirements as core functional specs. It focuses on creating a live, traceable evidence trail rather than a static file at the end.

Why is it important?

Because reactive documentation is a leading cause of compliance failure (60% of failures), regulatory penalties ($5M+ fines), and significant operational drag (up to 30% of budgets). CbD mitigates risk and accelerates speed-to-market.

How do you implement it?

- Integrate with your PLM/QMS: Use your system to enforce compliance checkpoints at design gates.

- Build a robust RTM: Create a bi-directional “golden thread” linking regulations to user needs, design inputs, design outputs, and V&V testing.

- Leverage Advanced Tools: Use digital twins for continuous simulation and integrate risk assessments (FMEA) directly into your design environment.

- Secure Buy-In: Frame the initiative around risk mitigation, speed-to-market, and executive accountability.

Frequently Asked Questions

- Q: This sounds expensive and time-consuming to set up. What’s the ROI?

The initial setup of workflows and templates is an investment, but it’s dwarfed by the cost of reactive compliance. The ROI comes from several areas: avoiding fines and penalties, eliminating the massive labor costs of last-minute documentation scrambles, reducing the risk of costly product recalls, and accelerating your time-to-market by days, weeks, or even months. The 30% operational budget consumed by manual compliance is the cost you’re already paying. CbD is the investment to eliminate that cost. - Q: Our engineering teams are already overloaded. How can we add this without slowing them down?

Initially, there can be a learning curve. However, a well-implemented CbD system actually removes work from engineers in the long run. Instead of being pulled into frantic documentation hunts before a launch, they document their decisions as they make them in the systems they already use. It shifts the effort from a massive, stressful peak at the end of the project to small, manageable increments throughout. The automation of evidence gathering means less administrative burden, freeing them up to focus on innovation. - Q: We work in multiple markets with constantly changing regulations. Can this system keep up?

Absolutely. In fact, a CbD system is the only way to effectively manage a complex and dynamic regulatory landscape. By linking requirements directly to design components in your RTM, you can perform impact analysis almost instantly. When a regulation changes, you can immediately see every product, component, and test case affected. This allows you to respond proactively and efficiently with a comprehensive compliance platform, which is impossible when your documentation is scattered across static files and spreadsheets.

Experience the Future of ESG Compliance

The Compliance & Risks Sustainability Platform is available now with a 30-day free trial. Experience firsthand how AI-driven, human-verified intelligence transforms regulatory complexity into strategic clarity.

👉 Start your free trial today and see how your team can lead the future of ESG compliance.

The future of compliance is predictive, verifiable, and strategic. The only question is: Will you be leading it, or catching up to it?

Simplify Corporate Sustainability Compliance

Six months of research, done in 60 seconds. Cut through ESG chaos and act with clarity. Try C&R Sustainability Free.