2026 OECD Forum: Key Takeaways on Due Diligence in the Garment and Footwear Supply Chains

This blog was originally posted on 16th February, 2026. Further regulatory developments may have occurred after publication. To keep up-to-date with the latest compliance news, sign up to our newsletter.

AUTHORED BY EMILIA ASSENZA, SENIOR REGULATORY COMPLIANCE SPECIALIST AND TEAM LEADER, COMPLIANCE & RISKS

The OECD Forum on Due Diligence in the Garment and Footwear Sector, held on 11 and 12 February, was once again a premier gathering where the most pressing challenges within the garment and footwear supply chains have been discussed among government officials, industry executives, and labor representatives.

One of the primary objectives of the forum is to analyze current and emerging labour, human rights and environmental risks facing the sector, and outline effective mitigation approaches, by discussing strategies to align international standards with local realities. Some core themes emerged across the two-day sessions, which can be summarized as follows:

- Agility vs. Due Diligence: Navigating sudden supply chain shocks while maintaining rigorous human rights and safety standards

- Energy Transition: Balancing the urgent need for renewable energy adoption with the practical challenges of “certification fatigue” and the high costs of new technologies

- Supply Chain 4.0: Analyzing how e-commerce and AI-driven models are reshaping production speeds and the resulting impact on labor rights

- Worker Vulnerability: Increasing the visibility and legal protection of “hidden” workers, including waste pickers and home-based laborers who often operate outside formal regulatory frameworks

For a deep dive into Supply Chain Due Diligence in Europe, download our whitepaper for key trends in 2025 and areas to watch in 2026.

Due Diligence in Informal Settings

The second session of day 1 highlighted the urgent need to embed informal workers into responsible business practices. The Chairman of the Kenya National Waste Pickers Welfare Association spoke powerfully about the risks of waste pickers in Kenya, particularly in light of the upcoming Extended Producer Responsibility (EPR) schemes. He warned that profit-driven models often fail to integrate waste pickers, despite their critical role in recycling value chains. Waste pickers face daily exposure to hazardous plastics, chemicals, landfill fumes, and significant health risks – without insurance or social protection. However, through collective organizing, they are building a stronger voice to engage with institutions and prepare for emerging regulations. EPR frameworks could empower waste pickers if designed inclusively, calling for policymakers and industry leaders to bring them to the table and ensure their realities are reflected in policy design.

From a supply chain perspective, brands in the panel shared their journey in developing home-based workers policies, extending protections to previously hidden informal workers, particularly in remote communities. Historically excluded and classified as high-risk in assessments, home-based workers are now gaining more visibility. Policies should not prohibit home-based work, but regulate it under legal frameworks aligned with health and safety standards and the company’s code of conduct, supported by responsible purchasing practices.

A key takeaway from the session was that due diligence must take place where the work actually happens, requiring risk-based approaches adapted to local contexts, engagement beyond the manufacturing stage – including recycling – and continuous, shared responsibility.

Supply Chains 4.0: Due Diligence Implications

The forum also looked toward the future, specifically how Supply Chain 4.0 and e-commerce are reshaping the industry.

The first session of Day 2, “Supply Chains 4.0: Due Diligence Implications of E-Commerce-Driven Business Models,” examined how ultra-fast, demand-driven models are reshaping global supply chains and challenging traditional responsible business conduct tools.

Anithra Varia from the Business & Human Rights Resource Centre shared findings from a 2024 benchmark of 65 garment brands, which revealed an average score of just 25 out of 100 on labour rights disclosure. Particularly striking was that purchasing practices scored zero across the sample, highlighting systemic pressures created by speed and fragmentation. These pressures often cascade down the supply chain, leading to subcontracting in less visible tiers where risks -including unsafe working conditions and forced labour – intensify. Traditional audit-based monitoring is not working anymore. Due diligence must therefore evolve beyond mapping and disclosure to meaningfully integrate purchasing practices, worker voice, and trade union engagement. Credibility of due diligence must be maintained in fast moving supply chains.

From an industry and policy perspective, speakers emphasized the need for both adaptation and regulation. Digitalization enables continuous monitoring of labour hours and environmental indicators, embedding due diligence into daily operations rather than limiting oversight to periodic audits. To tackle overproduction and textile waste, it is necessary to extend traceability beyond Tier 1 suppliers and strengthen forced labour safeguards.

AI will further accelerate product development, potentially widening the gap between technological speed and workers’ capacity. The overarching takeaway was clear: fast fashion and e-commerce-driven models are here to stay, but due diligence frameworks, regulatory approaches, and collaborative efforts must adapt to manage their evolving risk profile.

Due Diligence to Respond to Climate-Related Impacts on Workers

Another point of discussion of day 2 was the impact of climate change on workers. The session underscored how extreme heat, flooding, and water scarcity are present realities disrupting the garment and footwear production.

Panelists highlighted how adaptation measures are most effective when responsibility is shared across the value chain, rather than placed solely on workers or individual suppliers. Pilots introducing financial safety nets before climate shocks demonstrated that better working conditions – particularly in response to heat stress – can also improve productivity.

From the supplier perspective, it was discussed how investments in low-emission machinery, solar energy, and certified green factories are necessary to improve air quality, thermal comfort, ventilation and water access. However, suppliers noted limited brand engagement on adaptation and stressed that not all factories have equal technical capacity, data, or financial resources to respond effectively. Adaptation must be embedded into brands’ due diligence systems, supported by incentives and genuine collaboration.

Speakers also addressed the question of accountability and cost-sharing. The central question is: who should pay for climate adaptation? Workers cannot bear the burden; therefore brands, suppliers, governments, and even consumers must all contribute.

Climate risks – particularly extreme heat – to be systematically integrated into due diligence processes, including unannounced inspections to capture real working conditions. A recurring theme was the need to listen directly to workers, whose requests are often basic yet critical: adequate ventilation, access to water, medical support, and fair purchasing practices that account for climate realities. The key takeaway was clear: climate change must become a core component of due diligence, supported by clear heat policies, temperature tracking, worker engagement, and shared responsibility across the supply chain.

Interested in Emerging Human Rights Due Diligence Regulations across the globe? Check out our guide!

Conclusion

The 2026 OECD Forum on Due Diligence in the Garment and Footwear Sector reaffirmed that due diligence is no longer a compliance exercise, but a strategic necessity to build resilient, transparent, and future-ready supply chains. Across discussions on supply chain shocks, informal work, digital transformation, and climate change, one central message emerged: responsible business conduct must evolve to reflect today’s structural realities.

Whether addressing the pressures of ultra-fast production, the invisibility of informal workers, or the growing impact of extreme heat, effective due diligence requires deeper collaboration, stronger worker voice, and shared accountability across brands, suppliers, governments, and consumers.

Looking ahead to 2026, the sector must move decisively from reactive risk management to proactive resilience-building, ensuring that human rights, environmental sustainability, and commercial agility are all taken into account.

Key Takeaways for 2026

- Shared responsibility is non-negotiable: Supply chain shocks, climate adaptation, and fair purchasing practices require collective solutions. Workers cannot bear the costs alone – brands, suppliers, governments, and consumers must share risks and responsibilities.

- Due diligence must evolve beyond audits: Traditional compliance tools are insufficient for fast-moving, fragmented, and informal supply chains. Embedding purchasing practices, worker voice, climate risks, and digital monitoring into core operations is essential to maintain credibility.

- Resilience depends on inclusion: From waste pickers to home-based workers and factory employees facing extreme heat, due diligence must reach where work actually happens. Greater visibility, legal recognition, and meaningful engagement with workers are key to building stronger and more sustainable supply chains.

Stay Ahead Of Regulatory Changes in Due Diligence in the Garment and Footwear Supply Chains

Want to stay ahead of regulatory developments in Due Diligence in the Garment and Footwear Supply Chains?

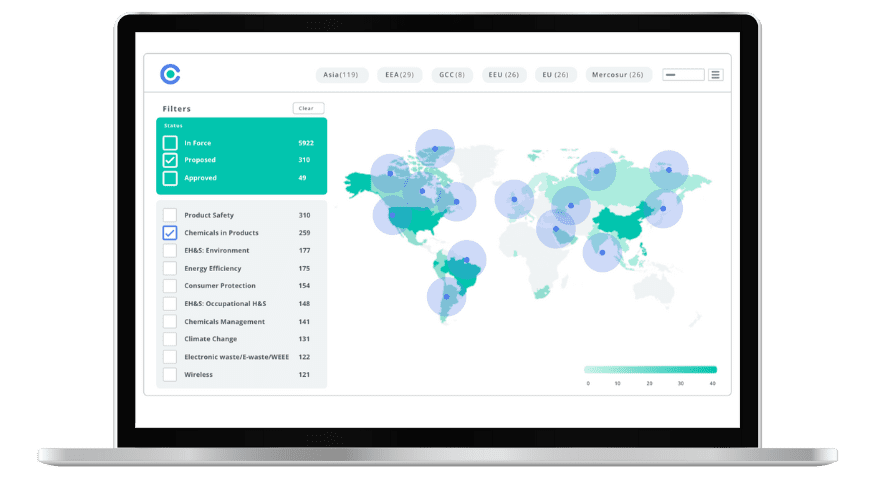

Accelerate your ability to achieve, maintain & expand market access for all products in global markets with C2P, your key to unlocking market access, trusted by more than 300 of the world’s leading brands. C2P is an enterprise SaaS platform providing everything you need in one place to achieve your business objectives by proving compliance in over 195 countries.

C2P is purpose-built to be tailored to your specific needs with comprehensive capabilities that enable enterprise-wide management of regulations, standards, requirements and evidence.

Add-on packages help accelerate market access through use-case-specific solutions, global regulatory content, a global team of subject matter experts and professional services.

- Accelerate time-to-market for products

- Reduce non-compliance risks that impact your ability to meet business goals and cause reputational damage

- Enable business continuity by digitizing your compliance process and building corporate memory

- Improve efficiency and enable your team to focus on business critical initiatives rather than manual tasks

- Save time with access to Compliance & Risks’ extensive Knowledge Partner network

Simplify Corporate Sustainability Compliance

Six months of research, done in 60 seconds. Cut through ESG chaos and act with clarity. Try C&R Sustainability Free.