A Practical Guide to Environmental Requirements by Product Category

THIS BLOG WAS WRITTEN BY THE COMPLIANCE & RISKS MARKETING TEAM TO INFORM AND ENGAGE. HOWEVER, COMPLEX REGULATORY QUESTIONS REQUIRE SPECIALIST KNOWLEDGE. TO GET ACCURATE, EXPERT ANSWERS, PLEASE CLICK “ASK AN EXPERT.”

The overwhelm is real. Staring at a spreadsheet of product SKUs, mapping them against a dizzying acronym soup of global regulations – WEEE, RoHS, REACH, EPR, and now the looming ESPR. It feels less like compliance management and more like trying to solve a Rubik’s Cube in the dark. One wrong move in one market, and access is denied, fines are levied, and products are stuck in customs.

The core problem isn’t a lack of information. It’s the opposite. You’re drowning in it. Governmental sites are dense and fragmented. Consultant blogs are often too narrow. And nobody seems to connect the dots between a new directive out of Brussels and the very real operational changes you need to make in your supply chain today.

The landscape has fundamentally shifted. Compliance is no longer a reactive, check-the-box exercise. It’s a proactive, design-level mandate that impacts everything from material sourcing to data management. This guide is built to cut through the noise. It’s not another list of regulations. It’s a strategic briefing designed for people who have to actually get this done – connecting the what (the law), the how (the operation), and the why now (the financial risk).

Table of Contents

- The 2025 Compliance Mandate: Why Fragmentation is Your Biggest Risk

- Compliance Fundamentals by Core Product Category

- The Shift from Reporting to Redesign

- The Operational Burden of Proving Compliance

- The Supply Chain Data Challenge

- Your Compliance Partner Evaluation Checklist

- Frequently Asked Questions

The 2025 Compliance Mandate: Why Fragmentation is Your Biggest Risk

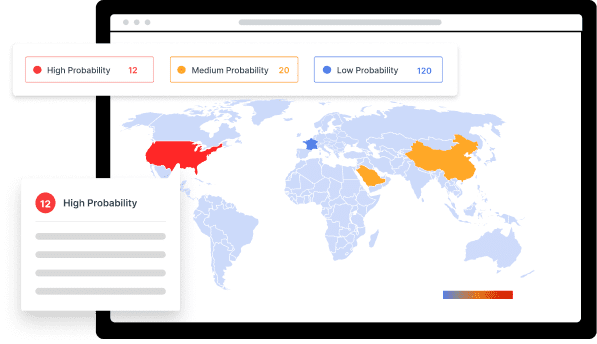

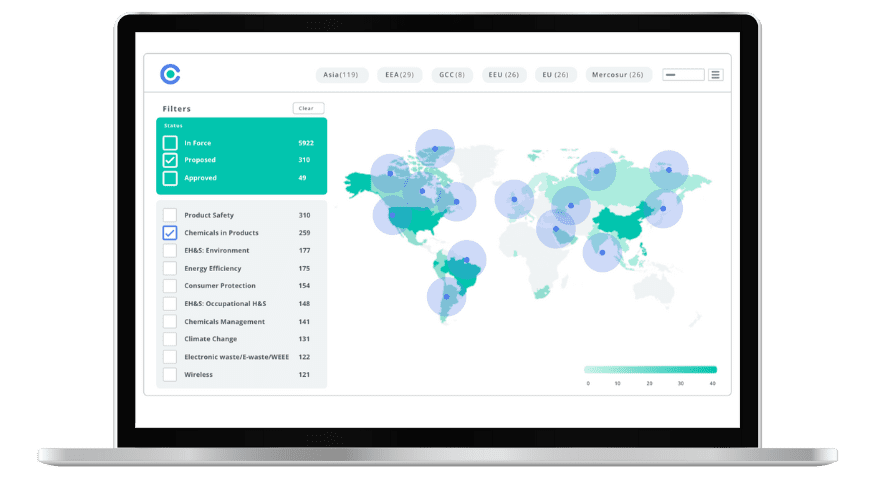

The single biggest threat to your market access isn’t a specific regulation; it’s the sheer, crushing weight of all of them at once. When manufacturers are surveyed, the same three challenges surface time and again: regulatory fragmentation, supply chain complexity, and the high cost of investment. They are all sides of the same problem. You can’t manage a complex global supply chain if you’re tracking fragmented regulations in a spreadsheet.

And the stakes are only getting higher. This isn’t just about buying a new tool. This figure represents a massive, industry-wide scramble to get a handle on risk. Investing in a streamlined compliance management system is no longer a competitive advantage; it’s becoming the minimum requirement for staying in the game.

Compliance Fundamentals by Core Product Category

While every product is unique, regulations tend to cluster around specific categories. Understanding these clusters is the first step toward building a coherent strategy. Think of this as your master map, connecting product types to their primary compliance mandates.

Electronics: The Triple Threat of Chemicals, Waste, and Design

No category is more heavily regulated. If you make electronics, you’re juggling restrictions on hazardous substances, end-of-life responsibilities, and now, forward-looking design requirements.

- RoHS (Restriction of Hazardous Substances): The foundation. This EU directive restricts the use of specific hazardous materials (like lead, mercury, and cadmium) in electrical and electronic equipment. It’s the price of entry for the EU market, but similar regulations exist worldwide.

- WEEE (Waste Electrical and Electronic Equipment): The end-of-life mandate. WEEE makes producers financially responsible for the collection, recovery, and recycling of their products. This involves registering with producer responsibility organizations (PROs) and reporting on products placed on the market.

- ESPR (Ecodesign for Sustainable Products Regulation): The future. This is the big one. ESPR is expanding ecodesign principles beyond energy efficiency to include durability, repairability, and recyclability. It will also mandate a Digital Product Passport (DPP), requiring you to provide detailed sustainability data for each product. More on this later.

Textiles & Apparel: The EPR Revolution Takes Hold

The textile industry has long flown under the radar, but that’s changing fast. The focus is squarely on waste and producer responsibility.

- Extended Producer Responsibility (EPR): This is the dominant model. In the EU and a growing number of U.S. states (like California and New York), producers are being made responsible for the entire lifecycle of their products, especially post-consumer waste. This means funding and managing take-back and recycling programs.

- ESPR Applicability: Textiles are a priority category under the EU’s ESPR. This will bring sweeping changes, including potential bans on the destruction of unsold goods, mandatory recycled content, and DPP requirements.

Batteries: Powering Up for Full Lifecycle Responsibility

Given their chemical composition and critical role in the green transition, batteries face some of the most stringent lifecycle regulations.

- The EU Battery Regulation: This is a comprehensive, “closed-loop” mandate. It covers everything from sourcing raw materials and carbon footprint declarations to recycled content minimums, collection targets, and labeling requirements. It applies to all batteries – portable, industrial, and electric vehicle – and demands unprecedented supply chain transparency.

Packaging: Beyond Recycling to Reduction and Reuse

Packaging compliance has been around for decades, but the focus is sharpening from simple recycling to a more circular approach.

- EPR for Packaging: This is the global standard. Companies placing packaged goods on the market must pay fees to PROs to fund the collection and recycling of that packaging. Fee structures are increasingly complex, with “eco-modulation” offering lower fees for more sustainable packaging (e.g., easily recyclable, high recycled content).

- PPWR (Packaging and Packaging Waste Regulation): The EU’s upcoming PPWR will push further, setting mandatory reuse targets, restricting certain single-use formats, and requiring all packaging to be fully recyclable by 2030.

The Shift from Reporting to Redesign

For years, compliance was about reporting what was already done. You’d test for restricted substances, weigh your packaging, and file your reports. That era is over. The new wave of regulations, particularly in the EU, forces compliance into the earliest stages of product development.

The ESPR Game-Changer: Welcome to the Era of the Digital Product Passport

The Ecodesign for Sustainable Products Regulation (ESPR) is not just another regulation; it’s a fundamental rewiring of how products are made and sold in Europe. Its core principle is that sustainability must be built-in, not bolted on.

Think about what this means. You will be legally required to design products that are more durable, easier to repair, and simpler to recycle. And the mechanism for proving this is the Digital Product Passport (DPP). The DPP is a digital record that will trace a product’s journey from raw materials to recycling, providing consumers and regulators with transparent data on its environmental impact. To be ready for the DPP, you need granular data on your supply chain and bill of materials that most companies simply don’t have at their fingertips today.

The Chemical Crackdown: Navigating the End of ‘Forever Chemicals’

Alongside design mandates, a massive chemical reset is underway. Per- and polyfluoroalkyl substances (PFAS), often called “forever chemicals,” are facing sweeping restrictions. The EPA has recently announced its new PFAS Action Plan to combat contamination, and a broad EU restriction under REACH is on the horizon.

This isn’t just a reporting issue. It demands immediate product reformulation. The water-resistant coating on your jackets? The non-stick surface on your cookware? The stain-proofing on your furniture? All of these likely rely on chemicals that will soon be banned. Companies that aren’t actively engaged in green chemistry and re-engineering their products right now are facing a future where their flagship products could be illegal to sell.

The Operational Burden of Proving Compliance

It’s one thing to know the rules. It’s another to prove you’re following them. This is where the operational rubber meets the regulatory road, and it’s often a painful, resource-intensive process.

Take the creation of an Environmental Product Declaration (EPD). An EPD is a standardized document that communicates the environmental impact of a product, and it’s increasingly required for green procurement and market access. But creating one is a major undertaking.

Here’s a simplified look at the workflow:

- Define Goal & Scope: What part of the product lifecycle will you analyze?

- Find the PCR: Locate the specific Product Category Rules that govern your product type.

- Collect Data: Gather exhaustive data from your entire supply chain – energy use, raw material inputs, transportation, waste output.

- Conduct a Life Cycle Assessment (LCA): Use specialized software to model the environmental impacts based on your data.

- Compile the EPD Report: Draft the report according to the PCR.

- Third-Party Verification: An independent expert must verify your LCA and EPD.

- Registration & Publication: Submit your verified EPD to a program operator.

Each step is complex, expensive, and requires deep expertise. Trying to manage this process manually across multiple product lines is a recipe for errors and delays. It highlights the critical need for a centralized platform to streamline compliance management and turn a burdensome process into a repeatable system.

The Supply Chain Data Challenge

Every new regulation, from EPR to ESPR, ultimately comes down to one thing: data. You cannot comply if you do not have accurate, auditable data from every corner of your supply chain.

Think about the requirements for a Digital Product Passport. You’ll need detailed information such as:

- The exact composition of your product.

- The source of your raw materials.

- The recycled content percentage.

- Information on repairability and spare parts.

Now, imagine trying to collect that information from a multi-tiered global supply chain using email and spreadsheets. It’s impossible. Your Tier 1 supplier might not have that data from their Tier 2 supplier. The data formats are inconsistent. There’s no single source of truth.

This is the hidden challenge that derails most compliance programs. Without a robust system for managing regulatory intelligence and supply chain data, you are constantly playing defense, reacting to data requests instead of having the information you need, when you need it.

Your Compliance Partner Evaluation Checklist

As you move from understanding the problem to solving it, choosing the right partner is critical. The market is growing, but not all solutions are created equal. Use this checklist to evaluate your options:

- Comprehensive Global Coverage: Does the solution cover all the regions where you operate and sell? Can it track regulations across 195 countries?

- Expert-Curated Intelligence: Is the information just scraped from websites, or is it analyzed and translated into actionable insights by a team of subject matter experts?

- Integrated Platform: Does it connect regulatory tracking with requirements management and evidence collection? Can you manage everything from a single source of truth, or is it just another silo?

- Proactive & Forward-Looking: Does the solution help you anticipate future regulations like ESPR and PFAS restrictions, or is it only focused on what’s law today?

- Scalability: Will the solution grow with you as you enter new markets and launch new products?

Frequently Asked Questions

- Q: What’s the biggest mistake companies make in product compliance?

The most common mistake is being reactive. They wait for a regulation to become law or for a customer to ask for compliance data before they act. By then, it’s too late. The new standard is proactive compliance – integrating regulatory intelligence into the product design and supply chain management process from day one. - Q: Can we manage global compliance with an in-house team and spreadsheets?

For a very small company with one product in one market, perhaps. But for any company operating at scale, it’s not feasible. The risk of human error is immense, it’s impossible to keep up with the pace of change, and you have no institutional memory when an employee leaves. The complexity of modern regulations necessitates a dedicated compliance management platform. - Q: What is the real cost of non-compliance?

It’s much more than just fines. The true cost includes lost sales from being locked out of a market, expensive product redesigns at the last minute, damage to your brand reputation, and the massive internal resource drain of scrambling to fix a problem that could have been prevented. In a world of green procurement, non-compliance can mean losing your biggest customers.

Ready to take control of your compliance complexity? Discover how C2P can help you navigate the evolving regulatory landscape and unlock global market access with confidence.

Experience the Future of ESG Compliance

The Compliance & Risks Sustainability Platform is available now with a 30-day free trial. Experience firsthand how AI-driven, human-verified intelligence transforms regulatory complexity into strategic clarity.

👉 Start your free trial today and see how your team can lead the future of ESG compliance.

The future of compliance is predictive, verifiable, and strategic. The only question is: Will you be leading it, or catching up to it?

Simplify Corporate Sustainability Compliance

Six months of research, done in 60 seconds. Cut through ESG chaos and act with clarity. Try C&R Sustainability Free.