Ask Our Experts: Our Most Popular Questions on Food Contact Materials

This blog was originally posted on 20th November, 2025. Further regulatory developments may have occurred after publication. To keep up-to-date with the latest compliance news, sign up to our newsletter.

Food contact materials (FCM) are either materials and articles intended to come into contact with food or reasonably expected to come into contact with food. These materials can transfer substances into food. As such, they must be manufactured to prevent unsafe levels of contamination and comply with regulations. The main concern is the potential migration of chemicals from the material into the food, which could affect its safety, smell and taste.

This Q&A tackles recent customer inquiries head-on, delving into the specifics on testing, certification, and labelling obligations across major jurisdictions. It summarises the mandatory Chinese GB standards that would apply to polypropylene (PP) and thermoplastic rubber (TPR) materials intended for food contact, clarifies the scope of EU food contact rules as they apply to product components, outlines labelling requirements in the EU, USA, China and Switzerland, and explains significant updates to the EU Plastics Regulation (EU) No 10/2011. It also addresses national obligations under Finland’s Food Act 297/2021, particularly regarding the use of designated laboratories for operator self-monitoring. Together, these provide a consolidated reference for companies manufacturing or selling FCM products in multiple markets.

Want to find out more about Food Contact Materials? Check out our blog Key Takeaways from the Food Contact Asia Conference 2025.

Testing and Certification of Polypropylene and Thermoplastic Rubber Materials in China

What mandatory Chinese tests/certifications apply to polypropylene and thermoplastic rubber materials intended for food contact?

Applicable GB Standards

For polypropylene and thermoplastic rubber food contact materials and products to be sold in China, there are some mandatory Chinese National Food Safety Standards known as GB Standards that must be complied with.

- China: General Safety Requirements for Food Contact Materials and Articles, Standard GB 4806.1-2016

This standard applies to all FCMs in China, and it sets the overarching safety principles and prescribes the requirements for proper product labelling. The standard also mandates a Declaration of Conformity (DoC). A draft revision to this 2016 standard is currently under development: China: General Safety Requirements for Food Contact Materials and Articles, Draft Standard GB 4806.1-20XX, April 2023 - China: National Food Safety Standard on Food Contact Plastic Materials and Articles, Standard GB 4806.7-2023

This is the material-specific standard which would be relevant for the polypropylene components in food contact materials. The standard provides the specific technical requirements for plastic materials, including a positive list of approved resins and additives. It also covers physical and chemical indicators, including migration limits. The standard also covers unvulcanised thermoplastic elastomer materials that come into contact with food. - China: National Food Safety Standard Rubber Materials and Products for Food Contact, Standard GB 4806.11-2023

This is the material-specific standard which would be relevant for the thermoplastic rubber components in food contact materials. The standard provides the specific technical requirements for rubber materials and products, including vulcanised thermoplastic elastomer and lists the permitted base materials for rubber materials and products used in food contact. - China: National Food Safety Standard for the Use of Additives in Food Contact Materials and Articles, Standard GB 9685-2016

This standard is core for regulating the use of additives and contains a “positive list” of approved additives for various materials, including plastics and rubber. This standard would ensure that any additives used in polypropylene and TPR materials are on the approved lists and comply with the specified usage scope, maximum limits and migration limits. Additionally, a draft revision to this standard is underway: China: National Food Safety Standard for the Use of Additives in Food Contact Materials and Articles, Draft Standard GB 9685-20XX, July 2025 - China: National Food Safety Standard General Rules for Migration Testing of Food Contact Materials and Articles, Standard GB 31604.1-2023

This standard establishes the general rules for conducting migration tests of substances from food contact materials into food. The migration testing is conducted to ensure that the material does not release harmful amounts of chemicals. - China: General Hygiene Principles for the Production of Food Contact Materials and Products, Standard GB 31603-2015

This standard specifies the hygiene controls and management requirements for the entire production process, from raw material procurement to final product packaging and storage. Adherence to this standard would demonstrate that the FCMs are manufactured under safe and hygienic conditions.

EU’s Food Contact Materials (FCM) Regulation (EC) No 1935/2004

Are scissor handles and knife handles considered food contact articles under this regulation?

Scope of Regulation

Under the EU’s Food Contact Materials (FCM) Regulation (EC) No 1935/2004, FCM applies to all materials and articles, which in their finished state: are intended to be brought into contact with food; or are already in contact with food; or can reasonably be expected to be brought into contact with food or to transfer their constituents to food.

As per the EU FCM regulation, it not only covers parts that are intended to come into contact with food but also parts that can be “reasonably expected” to come into contact with food during the normal use.

For a knife and a pair of scissors, it is highly foreseeable that the handles might also come into contact with food. Therefore, all components of a food contact product that could “reasonably be expected” to come into contact with food need to be certified as food contact safe.

Labelling Requirements for Food Contact Material Products

What are the labelling requirements for food contact material (FCM) products, particularly lunch packs for EU, USA, China and Switzerland? Beyond the information such as COO, material composition and manufacturer details, are there any additional labelling elements we should be aware of? Are there any mandatory warnings or disclaimers required to ensure safe consumer use?

European Union

Article 15 of “EU: Materials and Articles Intended to Come into Contact with Food, Regulation (EC) No 1935/2004″ prescribes that materials and articles, which are not yet in contact with food (similar to lunchboxes), when placed on the market, must include either the words “for food contact”, a specific indication of its use, or the glass and fork symbol. Furthermore, the regulation is also supplemented by specific measures for certain materials. For example, for plastic FCMs, you may refer to “EU: Plastic Materials Intended to Come into Contact with Food, Regulation (EU) No 10/2011” and the Amendment (“Regulation No. 2025/351“) provides new labelling requirements for final repeated use FCMs.

United States

Unlike the EU, the USA for FCM focuses more on the safety of the substances in the material rather than standardised labelling on FCM as provided in 21 CFR Part 1. The primary requirement is that the FCM must be composed of substances safe for their intended use and must not adulterate the food by transferring components in unsafe or harmful quantities, as prescribed in 21 CFR Part 174 (“USA: Food and Drugs, Indirect Food Additives, General, 21 CFR 174, Regulation, 1977“). That being said, state-level laws may impose additional warnings, such as California Proposition 65 (“California (USA): Proposition 65, Safe Drinking Water and Toxic Enforcement Act of 1986“) requires a warning label on products, including FCMs, that expose consumers to chemicals that cause cancer or reproductive harm.

China

The general labelling requirements of FCM in China can be found in “China: General Safety Requirements for Food Contact Materials and Articles, Standard GB 4806.1-2016″ and changes to its labelling requirements can also be accessed in its draft revisions (“China: General Safety Requirements for Food Contact Materials and Articles, Draft Standard GB 4806.1-20XX, April 2023”.

Switzerland

Similar to the EU, the Ordinance (“Switzerland: Materials and Articles in Contact with Food, Ordinance, December 2016″) clarifies that FCMs must either bear the words “suitable for food”, a specific statement related to their use or a glass and fork symbol.

2025 Update to EU Plastic Materials Intended to Come into Contact with Food, Regulation (EU) No 10/2011

Could you help clarify the changes/differences to a couple of sections of EU 10/2011 with the 2025 revision?

1. Testing – Is the testing done by the final article manufacturer or each component supplier?

2. What are the documentation changes between the current revision and the old revision, particularly for materials not currently in contact with food?

3. What is the proper wording/citation that should be used for regulatory compliance claims?

Testing

The responsibility for testing remains shared, which means suppliers provide the information and evidence for their specific component, while the final manufacturer ensures that the finished product meets all requirements. However, the revision emphasises the requirements on the material and intermediate stage suppliers to provide comprehensive documentation that enables the final article manufacturer to prove compliance. Suppliers must provide adequate information on restricted substances, including non-intentionally added substances (NIAS). This covers impurities, reaction intermediates, or decomposition/reaction products formed during the plastic’s manufacturing that could be present in the final food contact material or article. Additionally, Annex V is revised to specify the rules on the verification of compliance testing, and at point 2.1.6, a new requirement is introduced to guarantee that migration of constituents does not increase during repeated use cycles.

Documentation Changes

The 2025 revision significantly enhances the information required in the supporting documentation (Article 16 is completely replaced), particularly regarding purity. Manufacturers must ensure that the documentation on the composition and degree of purity of substances is made available to competent authorities upon request. In Annex IV of point (6), the DoC is amended to require disclosing any non-intentionally added substances (NIAS) that could cause a compliance breach. This specifically includes substances contained in the intermediate material with unruled-out genotoxicity and whose migration is estimated to exceed 0.00015 mg/kg food.

On point (13) of page 4 of the 2025 revision text, the provision reaffirms that Article 15 of the Framework Regulation No (EC) No 1935/2004 requires materials and articles not yet in contact with food, if necessary, to be accompanied by special instructions for safe and appropriate use.

Regulatory Compliance Claims

The Declaration of Compliance (DoC), which is required at all marketing stages other than at the retail stage, should contain the information included in Annex IV of the EU Regulation 10/2011. Since the regulation does not provide a model citation for the DoC, confirming the proper format is impossible. That being said, the inclusion of a full and detailed citation of the relevant article and regulation may be regarded as best practice for declaring compliance.

Finnish Food Act 297/2021

Section 35 of the Finnish Food Act 297/2021 provides that certain food contact materials/articles own-check samples should be tested in a lab designated by Finnish Authorities.

1. What is the own-check sample meant by this regulation? Is it for existing products on the market or should new product development testing for market access be included as well?

2. Does this require testing for all food contact material/article own-check samples through designated lab if companies headquarters are in Finland? Or does this apply to those products either produced or sold in Finland?

3. Does the EU harmonized regulations for e.g. plastics make any difference here, that required only for materials having harmonized EU regulation?

Definition of Own-check Sample

“Own-check samples” are part of a mandatory, self-regulated system for all food and food-contact material businesses under Section 15 of the Finnish Food Act (297/2021). This system requires the business to establish a procedure to identify, manage, and record all hazards associated with its operations, ensuring compliance with food safety laws.

The samples are taken and tested to verify that the business is meeting specific safety standards defined by various EU and Finnish regulations. These standards cover key areas such as microbiological criteria (EC 2073/2005), specific hygiene rules for food of animal origin (EC 853/2004), Finnish rules on zoonoses (316/2021), and EU rules for contaminants like acrylamide (EU 2017/2158) and food contact materials.

It is important to note that the regulated testing obligation applies only to products already on the market. While developing a new product, these criteria can be considered as a guide, but the samples taken during the development phase do not need to be tested in a designated laboratory.

Scope of Regulation

The regulation applies to food contact materials that are produced or placed on the market in Finland as part of the operator’s food contact materials activity. Hence, Section 35 provides the obligation to use a designated laboratory for own-check samples in the food contact material operation based on the activities being carried out in Finland and not merely on the location of the company’s headquarters.

EU Harmonized Standards

Furthermore, the regulation states that it applies to the implementation of the EU legislation concerning food, food contact materials, food contact material activities and food control, provided that the implementation is not already legislated elsewhere. The requirement in Section 35 is a national implementation of the EU’s requirement for a self-monitoring system. It mandates the use of designated laboratories for required testing, regardless of whether the specific materials have harmonised EU-specific rules. Thus, it does not make a difference, and for FCMs (whether harmonised like plastics) where the testing is required under the operator’s self-monitoring plan to demonstrate compliance, that testing must be done by a Finnish authorised laboratory (official laboratory, national reference laboratory, or designated own-check laboratory).

Stay Ahead Of Regulatory Changes in Food Contact Materials

Want to stay ahead of regulatory developments in Food Contact Materials?

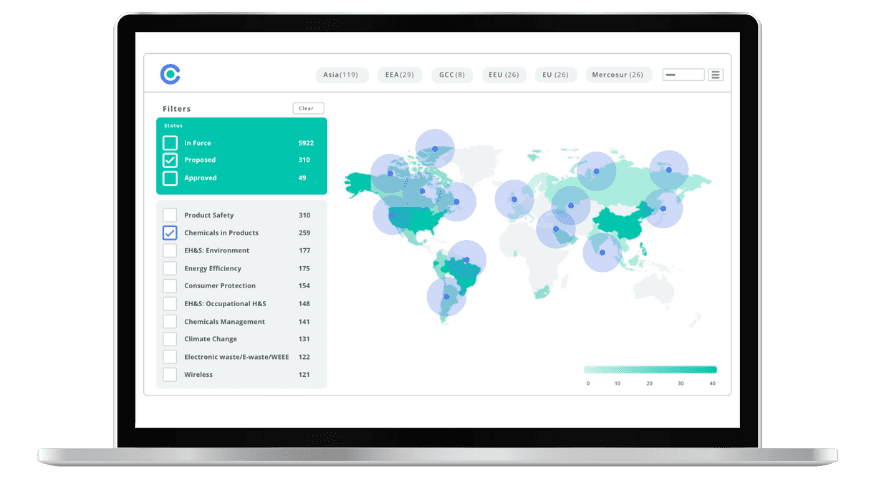

Accelerate your ability to achieve, maintain & expand market access for all products in global markets with C2P – your key to unlocking market access, trusted by more than 300 of the world’s leading brands.

C2P is an enterprise SaaS platform providing everything you need in one place to achieve your business objectives by proving compliance in over 195 countries.

C2P is purpose-built to be tailored to your specific needs with comprehensive capabilities that enable enterprise-wide management of regulations, standards, requirements and evidence.

Add-on packages help accelerate market access through use-case-specific solutions, global regulatory content, a global team of subject matter experts and professional services.

- Accelerate time-to-market for products

- Reduce non-compliance risks that impact your ability to meet business goals and cause reputational damage

- Enable business continuity by digitizing your compliance process and building corporate memory

- Improve efficiency and enable your team to focus on business critical initiatives rather than manual tasks

- Save time with access to Compliance & Risks’ extensive Knowledge Partner network

Simplify Corporate Sustainability Compliance

Six months of research, done in 60 seconds. Cut through ESG chaos and act with clarity. Try C&R Sustainability Free.