EU and UK Report on Non-Compliance of Apparel Products

This blog was originally posted on 6th February, 2024. Further regulatory developments may have occurred after publication. To keep up-to-date with the latest compliance news, sign up to our newsletter.

AUTHORED BY MARIA MARECKI, MARKET ACCESS MANAGER, COMPLIANCE & RISKS

Introduction

With a 56% growth in regulations over the past 5 years alone, it is more important than ever that apparel brands stay on top of non-compliance of apparel products.

In December 2023, the European Union and United Kingdom published the results of product testing enforcement projects. The focus of the European Chemicals Agency’s (ECHA) investigation was compliance with chemical substances restrictions, while the UK Office for Product Safety & Standards (OPSS) focused on safety and labeling.

In this blog, we give an overview of the results found on non-compliance of apparel products from the EU and UK.

European Union

ECHA published Forum for exchange of information on enforcement REF-10 project report on: Integrated chemical compliance of products, December 2023 detailing the results of an EU-wide enforcement project.

In 2022, national enforcement authorities in twenty-six EU countries checked 2,407 products. More than 400 were found to have breached the EU’s chemicals regulations.

Types of products investigated include electrical, sport, toys, fashion, and building products.

The REF-10 project focused on compliance with substances in articles under REACH, Persistent organic pollutants (POPs) restrictions and restrictions derived from the Toys and the RoHS Directives.

The overall non-compliance rate was 18%. The noncompliance rate for articles was 20%.

In the fashion category, 895 products were investigated. The non-compliance rate was 15%. The products with the highest non-compliance rate were bags (50%) and jewelry (23%). Other non-compliant products included were belts (7%), shoes (8%) and clothes (2%). The product group “Other” had a non-compliance rate of 5%. This group included outdoor textiles, oven gloves, masks, hairbands and key rings.

Non-compliance in the fashion category was mostly caused by phthalates and short chain chlorinated paraffins (SCCP) in soft plastic material, and lead and cadmium in jewelry.

Only 3% of textiles products were found to be non-compliant. Non-compliance was due to PFOA above the threshold limit value.

Chromium (VI) was found in leather and the non-compliance rate was 2%.

Enforcement measures observed for non-compliance included the issuance of written advice, public announcement, order, follow up activities still on-going, verbal advice, destruction of the product and re-export.

Overall, sanctions were not imposed in 53% of the cases. Fines were imposed in 18% of cases. Cases were escalated to the level of criminal complaints or handed over to the public prosecutor’s office in 13% of cases.

The report makes recommendations to duty holders. Duty holders are encouraged to set specific requirements to the supplier regarding high risk materials and substances (soft plastic, metal, SCCP, lead and phthalates). Duty holders should also ensure that suppliers have all the necessary documents that are needed for the given product type before placing the product on the market.

United Kingdom

The UK Office for Product Safety & Standards (OPSS) published Product Safety: Baseline Compliance Research December 2023 reporting on testing conducted on 700 products purchased between October 2021 and March 2022.

Products were sampled from both online and in-store.

Fifteen product types were chosen including: headphones, coin/button batteries, mobile phone chargers, oven gloves, and scatter cushions. The only clothing product testing was children’s nightwear.

The Nightwear (Safety) Regulations 1985 (as amended) establishes requirements for children’s nightwear. Children’s nightwear is defined as a child’s nightdress, pajamas, or dressing-gown. Child means being under 13.

All nightwear was tested against the following standards:

- BS 5722:1984, Flammability performance of fabrics and fabric assemblies used in sleepwear and dressing gowns; and

- BS EN 14878:2007, Textiles – Burning behaviour of children’s nightwear.

Labeling and marking requirements were also assessed.

The compliance rate for children’s nightwear was 84%. Of the 50 models tested 42 were found to be compliant. The eight non-compliant models were all purchased online.

All non-compliance was a result of manufacturers either failing to affix a label or not displaying the mandatory “Keep Away From Fire” (KAFF) warning as per the regulations.

The report notes that while there were failures regarding the warnings on these products, the products met the flammability requirements. The warnings are important as there will be children’s nightwear which lacks fire-retardant properties and warnings help consumers ensure that adequate precautions are taken.

OPSS followed up instances of non-compliance by writing to manufacturers and distributors setting out the nature and findings of the tests carried out and where appropriate recommending actions to deal with the non-compliances found.

OPPS notes that product compliance in this project reflects the products tested in this research only. The rate does not reflect national level compliance.

Stay Ahead Of Regulatory Changes and Non-Compliance of Apparel Products

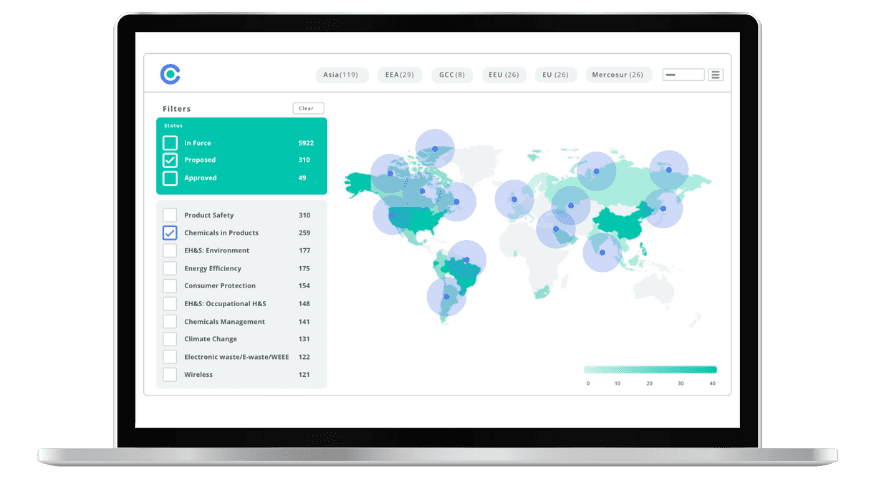

Accelerate your ability to achieve, maintain & expand market access for all products in global markets with C2P – Your key to unlocking market access, trusted by more than 300 of the world’s leading brands.

C2P is an enterprise SaaS platform providing everything you need in one place to achieve your business objectives by proving compliance in over 195 countries.

C2P is purpose-built to be tailored to your specific needs with comprehensive capabilities that enable enterprise-wide management of regulations, standards, requirements and evidence.

Add-on packages help accelerate market access through use-case-specific solutions, global regulatory content, a global team of subject matter experts and professional services.

- Accelerate time-to-market for products

- Reduce non-compliance risks that impact your ability to meet business goals and cause reputational damage

- Enable business continuity by digitizing your compliance process and building corporate memory

- Improve efficiency and enable your team to focus on business critical initiatives rather than manual tasks

- Save time with access to Compliance & Risks’ extensive Knowledge Partner network

Simplify Your Product Compliance Process with C2P

Design & build new products with full confidence you’ve met all compliance obligations