Potential PFAS Restrictions – Big Impact on Semiconductor Machinery Manufacturers

This blog was originally posted on 2nd June, 2023. Further regulatory developments may have occurred after publication. To keep up-to-date with the latest compliance news, sign up to our newsletter.

AUTHORED BY liz kimber, Principal Consultant, RINA

The proposed EU restriction (i) of around 10,000 per- and polyfluoroalkyl substances (PFAS) will have a significant impact on semiconductor machinery (equipment) manufacturers. This article briefly describes how this machinery is used, the criticality of the processes they perform, where PFAS are used, and the issues that may arise as a result of the proposed restriction.

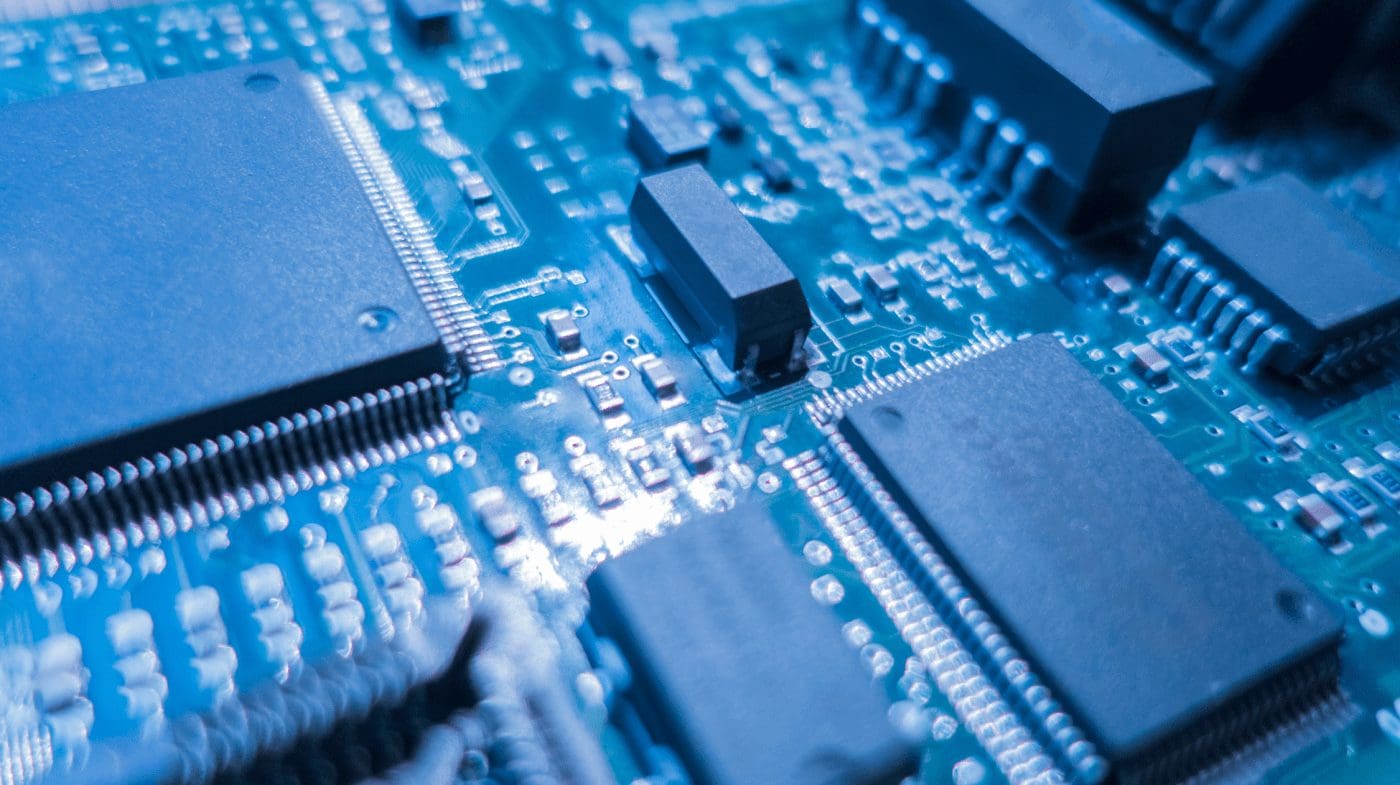

Machinery and Semiconductor Device Production

Machinery is integral to the production of semiconductor devices. There are multiple, sequential, processing steps involved in the production of semiconductor devices. Each step presents different technological challenges and requires specialised manufacturing equipment. The design development and qualification of this specialised equipment takes several years with considerable capital investment in R&D. The machinery design, once qualified for full-scale production, is then tightly controlled due to the sensitivity of the production processes.

Potential Impact on Semiconductor Machinery

A simple modification such as changing a component due to obsolescence could have significant ramifications for production yield or safety if the replacement does not meet the exact same form, fit, and functional requirements of the original component. The further the machinery is positioned in the chain of production process steps, the greater the potential cost of a change becomes. As well as the process tools themselves (e.g., implanters, etching tools, deposition tools & photolithography), there is a significant plethora of infrastructure support equipment, such as exhaust abatement units, chemical distribution systems, and waste management systems. All of these have the potential to impact production rates and facility safety.

Uses of PFAS in Semiconductor Machinery

The reason why the proposed EU restriction will have an impact on semiconductor machinery manufacturers (and therefore all those who rely on the components they produce – both OEMs and users), is due to the many uses of PFAS substances in these systems. These uses of PFAS can be summarized as follows:

- In the formulations used in semiconductor processing steps e.g., surfactants, coatings, resists, and etching media – a restriction will drive semiconductor manufacturers to seek alternatives which may require complete re-evaluation of the machinery or even the development of a completely new equipment architecture.

- In components of the machinery themselves – many individual component parts, fluids & lubricants in semiconductor manufacturing equipment, and facilities infrastructure equipment, are dependent on PFAS-containing articles or substances to provide the required cleanliness and purity; chemical & permeation resistance; compatibility; inertness; temperature stability; low coefficient of friction; non-flammability; optical, mechanical and electrical properties; processability; and bacterial growth resistance. The impact of changing any of these on the device production process, environment, and safety would need to be fully evaluated. There is also the possibility that a restriction could trigger obsolescence and impact component part supply, which would hinder a machinery manufacturer’s ability to maintain its installed base of equipment.

A recently published paper, publicly available from the Semiconductor Industry Association (SIA)(ii), explores in-depth the impact of a potential PFAS restriction on not only semiconductor machinery manufacturers but the sector as a whole.

Current Status of the Proposed Restriction and What to Do

A six-month European Chemicals Agency (ECHA) consultation (iii) is currently underway, which is due to end on 25th September. The RAC (ECHA’s scientific committee for Risk Assessment) will review early responses to the consultation and will develop their opinion in parallel to the public consultation. They will publish their opinion 6 weeks after the end of the consultation. The SEAC (ECHA’s scientific committee for Socio-Economic Analysis) will review all socioeconomic arguments that respondents choose to submit in the consultation period and are likely to publish their responses between 22 March 24 and 22 June 2024, depending on the number of responses received.

There will then be an opportunity to comment on the SEAC and RAC opinions before they are issued to the European Commission, and the restriction is likely to be finally agreed and published in late 2024 or during 2025. There will then be the 18-month transition period.

Recommended Actions for Manufacturers

As previously recommended by RINA, manufacturers should:

- Review their PFAS uses as a matter of urgency, identifying all PFAS upon which their products rely.

- Respond to the consultation if affected by the PFAS restriction.

- Respond to the RAC and SEAC opinions when that consultation opens in approximately 12 – 15 months.

Market Insights Straight to Your Inbox

Get the most important regulatory updates straight to your inbox. Join 40,000+ product compliance & market access experts around the world!

Author

Liz Kimber, Principal Regulatory Consultant, RINA

Liz is a product compliance specialist and chartered mechanical engineer with over 30 years of experience in a broad range of manufacturing sectors, including energy, semiconductor, automotive and vacuum. Provider of technical consultancy to industry and public bodies on product regulation, specifically product safety legislation affecting electrical, electronic and mechanical equipment (ATEX, EMCD, LVD, Machinery Directive, PED), ecodesign and environmental legislation. Other skills include project management, new product development & introduction, product management & manufacturing optimisation.

She can be contacted at – liz.kimber@rina.org