The Global Electronics Compliance Risk Matrix: A 2025-2030 Roadmap for RoHS, REACH, PFAS & Beyond

THIS BLOG WAS WRITTEN BY THE COMPLIANCE & RISKS MARKETING TEAM TO INFORM AND ENGAGE. HOWEVER, COMPLEX REGULATORY QUESTIONS REQUIRE SPECIALIST KNOWLEDGE. TO GET ACCURATE, EXPERT ANSWERS, PLEASE CLICK “ASK AN EXPERT.”

The customs nightmare at 9 PM. An email lands from your APAC distributor. A shipment is stuck at customs. Something about a substance declaration form for a component you thought was cleared months ago. Your heart sinks. It’s not just the delay; it’s the gnawing uncertainty. Are there other blind spots? What else have we missed?

Look, navigating the world of electronics compliance in 2025 isn’t about memorizing acronyms. Anyone can tell you what RoHS or REACH stand for. The real challenge – the one that keeps engineering and compliance managers up at night – is managing a chaotic, constantly shifting matrix of global rules where a mistake doesn’t just mean a fine; it means losing market access.

This isn’t another glossary of terms. This is a strategic roadmap. It’s a risk mitigation handbook designed to move you from a reactive, fire-fighting posture to a proactive, future-proofed position. We’re going to dissect the most critical compliance frameworks, quantify the real financial stakes, and highlight the dangerous geopolitical divides that trip up even the most seasoned teams.

Table of Contents

- The Financial Wake-Up Call: Quantifying the True Cost of Non-Compliance

- The Core Compliance Trinity: A Practical Comparison of RoHS, REACH, and WEEE

- The Great Divide: Why EU Compliance Is Not China Compliance

- The New Risk Frontier: Navigating PFAS, ITAR, and State-Level Chaos

- Your 2030 Strategy: Preparing for the Circular Economy Mandates

- From Reactive Chaos to Proactive Control: Building Your Compliance Framework

- AI-Powered Snippet & Key Takeaways

- Frequently Asked Questions (FAQ)

- Don’t Just Manage Compliance – Master It

The Financial Wake-Up Call: Quantifying the True Cost of Non-Compliance

Let’s get right to it. The “cost” of non-compliance isn’t some abstract concept. It’s a number with a lot of zeros at the end.

Think about it this way: a single EU RoHS violation can trigger penalties reaching €100,000 per incident in certain member states. And that’s just the ticket price. A full-blown product recall in the electronics sector costs, on average, a staggering $11.71 million USD. In some documented cases, companies have lost over $150 million in sales from a single compliance failure.

But the most dangerous threat isn’t even the one-time fine. It’s the systemic risk. For a billion-dollar company, that’s a $40 million problem born from a single chemical oversight in a sub-component.

This isn’t just about avoiding penalties. It’s about protecting your right to operate. It’s about preventing forced product redesigns, avoiding crippling supply chain delays, and maintaining customers’ trust.

The Core Compliance Trinity: A Practical Comparison of RoHS, REACH, and WEEE

Everyone has seen the PowerPoint slides defining these three. But definitions don’t help you when you’re trying to build a compliance workflow. What matters is how they interact and where their demands diverge.

The Comparison Matrix: Scope, Requirements, and Methods

| Framework | Scope | Core Requirement | How You Comply |

|---|---|---|---|

| RoHS (Restriction of Hazardous Substances) | Product-Level. Applies to finished Electrical and Electronic Equipment (EEE). | Restriction. Prohibits specific hazardous substances (Lead, Mercury, Cadmium, etc.) above set concentration limits. | Technical Documentation. Creating a Technical File with supplier declarations, test reports, and a Declaration of Conformity (DoC). Primarily a self-declaration model in the EU. |

| REACH (Registration, Evaluation, Authorisation and Restriction of Chemicals) | Chemical-Level. Applies to all chemical substances on their own, in mixtures, or in articles. Broader than just electronics. | Information & Registration. You must identify and manage risks associated with the substances you manufacture and market. This often involves registering substances with ECHA, communicating information on Substances of Very High Concern (SVHCs) throughout the supply chain, and reporting to the SCIP (Substances of Concern in Articles as such or in Complex Objects/Products) database managed by ECHA. | Supply Chain Data Collection. You need comprehensive substance data from every supplier for every component to prove you are below the 0.1% weight-by-weight threshold for SVHCs. This is an ongoing data management challenge. |

| WEEE (Waste Electrical and Electronic Equipment) | End-of-Life. Applies to finished EEE and focuses on what occurs after the customer has completed using the product. | Producer Responsibility. You, the producer, are financially responsible for the collection, recovery, and environmentally sound disposal of your products at the end of their life. | Registration & Reporting. Registering with national producer responsibility schemes in each country you sell to, marking products with the “wheelie bin” symbol, and reporting the volume of EEE you place on the market. |

The key takeaway? RoHS is a product design rule. REACH is a supply chain intelligence rule. And WEEE is a market participation rule. You can’t solve one without impacting the others.

A 5-Step Workflow for Component-Level Compliance

Building a resilient program requires a systematic approach, not a series of one-off checks. Here’s a simplified workflow:

- Deconstruct Your Bill of Materials (BOM): Every single component, from the capacitor to the chassis screw, must be catalogued.

- Gather Supplier Declarations: Systematically request Full Material Declarations (FMDs) or Certificates of Compliance from every supplier in your chain. This is your first line of defence.

- Conduct a Risk Assessment: Not all suppliers are equal. A high-risk component from a new supplier in a loosely regulated region warrants more scrutiny (and potentially third-party testing) than a low-risk component from a long-term, trusted partner.

- Build Your Technical File: Consolidate all evidence – BOMs, supplier declarations, test reports, risk assessments – into an auditable Technical File. This is the proof you need if a market surveillance authority comes knocking.

- Implement Ongoing Monitoring: This is the step everyone misses. Regulations change. The REACH SVHC list is updated twice a year. You need a system to automatically flag when a substance in one of your products is suddenly reclassified as hazardous.

The Great Divide: Why EU Compliance Is Not China Compliance

One of the most expensive assumptions a company can make is that their EU Declaration of Conformity is a golden ticket for global market access. Nowhere is this more wrong than in China.

While China RoHS II and EU RoHS restrict many of the same substances, their enforcement mechanisms differ significantly. It’s a classic case of what vs. how.

The Testing Gap: Self-Declaration vs. Mandatory Third-Party Certification

In the European Union, the compliance model primarily relies on self-declaration. You are responsible for conducting due diligence, preparing your Technical File, and signing a Declaration of Conformity confirming that your product complies with applicable regulations. While you need to have supporting evidence to back up your claims, pre-market approval from a government body is generally not required.

China operates on a different philosophy. For electronic products that fall into their official MIIT “Compliance Management Catalogue,” the rules under GB 26572-2025 are far more stringent. Compliance often requires mandatory third-party testing conducted by accredited labs in China.

Here’s what that means in practice:

- EU Model: Collect supplier data → Assess risk → Create Technical File → Declare Conformity.

- China Model: Identify if product is in catalogue → Collect supplier data → Submit samples to a CNAS-accredited lab for testing → Obtain test reports for at least 70% of components → Certify compliance.

This isn’t a minor paperwork difference. It’s a fundamental shift in your product development lifecycle, adding significant cost, time, and logistical complexity. Assuming your EU process will work in China is a direct path to a blocked shipment.

The New Risk Frontier: Navigating PFAS, ITAR, and State-Level Chaos

The established frameworks are just the baseline. The real risk – and opportunity for competitive advantage – lies in understanding what’s coming next. The regulatory landscape is experiencing explosive growth, with a 1060% increase in regulations affecting the electronics sector since 2019 alone.

The PFAS “Forever Chemical” Crackdown

Per- and polyfluoroalkyl substances (PFAS) are a class of thousands of synthetic chemicals used in electronics for everything from cable insulation to semiconductor manufacturing. They are also under intense global scrutiny for their persistence in the environment.

The regulatory hammer is already falling. In the U.S., the TSCA Section 8(a)(7) Rule has created urgent reporting obligations for any company that has manufactured or imported PFAS since 2011. In the EU, a proposal is on the table for a near-total ban on PFAS. The challenge is immense because, for many companies, these “forever chemicals” are hiding deep within their supply chains, undocumented and untracked.

The National Security Blind Spot: Integrating ITAR and Export Controls

For any company in the defence, aerospace, or high-tech sectors, compliance is a two-front war. You can have a perfectly RoHS-compliant product that is illegal to ship because it violates export control regulations, such as the International Traffic in Arms Regulations (ITAR).

Here’s the dangerous intersection: a substance restricted for environmental reasons might also be a controlled material for national security reasons. Your environmental and trade compliance teams can no longer operate in silos. A truly robust compliance program integrates materials data with export control classifications to ensure you’re not just environmentally safe, but also legally exportable.

The Patchwork Problem: California’s Proposition 65

As if global regulations weren’t enough, you have to contend with powerful state-level rules. California’s Proposition 65 (Prop 65) requires businesses to provide warnings to Californians about significant exposures to chemicals that cause cancer, birth defects, or other reproductive harm.

The list of Prop 65 chemicals is massive and constantly updated. This creates a unique labeling and compliance challenge, forcing companies to manage a specific set of rules for a single – albeit massive – market. It’s the perfect example of why a one-size-fits-all global strategy is doomed to fail.

Your 2030 Strategy: Preparing for the Circular Economy Mandates

The regulations we’ve discussed are largely about what you can’t put in your products. The next wave of legislation focuses on what you must include: information, transparency, and sustainability.

The EU’s Ecodesign for Sustainable Products Regulation (ESPR) is the vanguard of this shift, and it’s bringing two game-changing concepts: the Digital Product Passport and the Right to Repair.

The Digital Product Passport (DPP): Your Supply Chain Under a Microscope

Imagine if every product you sold had a digital twin, a comprehensive record accessible via a simple QR code. That’s the future mandated by the Digital Product Passport.

The DPP will require you to provide granular data on:

- Material Composition: Not just restricted substances, but comprehensive material information.

- Supply Chain Traceability: Where components and raw materials came from.

- Circularity & Recycled Content: Proof of recycled materials used and information on how to recycle the product.

- Repairability Score: A rating of how easy the product is to repair.

This isn’t a simple labeling exercise. It’s a data management revolution. It will require unprecedented transparency across your supply chain, requiring you to collect, validate, and manage information you likely don’t have today. Companies that start building this data infrastructure now will have a massive advantage.

The Right-to-Repair Revolution: Designing for a New Reality

Driven by consumer demand and regulatory pressure, the Right-to-Repair movement is fundamentally changing product design. These new directives will mandate things like:

- Spare Parts Availability: Requiring manufacturers to make critical spare parts available for 7-10 years after a product is no longer sold.

- Design for Disassembly: Products must be designed to be easily taken apart with standard tools for repair.

- Access to Repair Information: Companies will be required to provide repair manuals and diagnostics to independent repair shops and consumers.

This forces compliance out of a silo and puts it squarely in the R&D and engineering departments. The design choices you make today will determine your compliance risk – and your logistics burden – for the next decade.

From Reactive Chaos to Proactive Control: Building Your Compliance Framework

The sheer volume and velocity of regulatory change have made manual compliance management obsolete. Trying to track thousands of components, hundreds of suppliers, and a patchwork of global rules using spreadsheets and email is no longer just inefficient; it’s negligent.

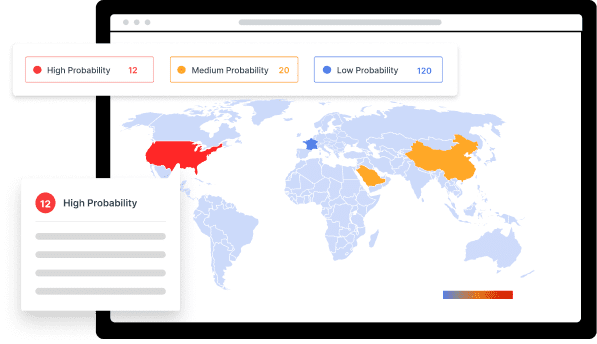

The only way to win is to move from a manual, reactive process to an automated, intelligent one. The goal is to build a centralized system – a single source of truth – that provides:

- Live Regulatory Intelligence: Real-time alerts when a regulation changes or a new substance is added to a restricted list.

- Automated Supply Chain Communication: Streamlined platforms for collecting and validating compliance data from your suppliers.

- Instantaneous Impact Analysis: The ability to see, in minutes, which of your products and product lines are affected by a new rule.

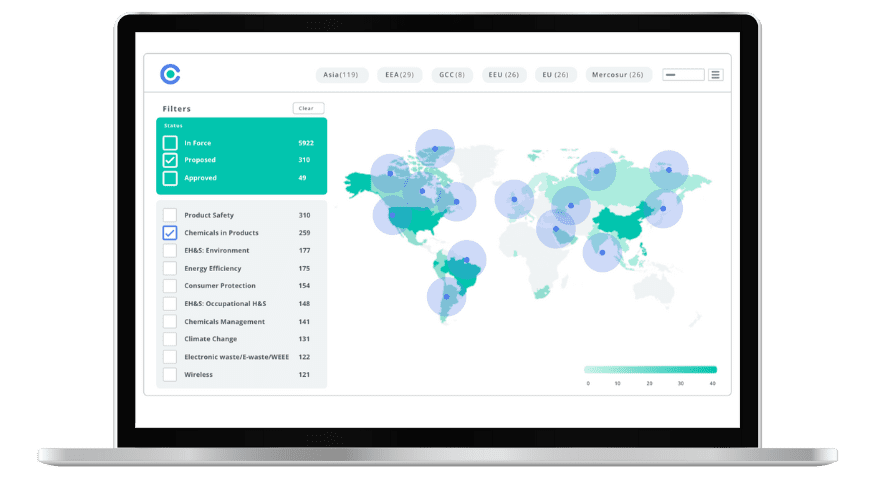

By leveraging a dedicated platform, you can streamline your global compliance management and transform your compliance department from a cost center into a strategic enabler of market access and innovation.

AI-Powered Snippet & Key Takeaways

- What is the main difference between RoHS and REACH? RoHS restricts specific hazardous substances in electrical and electronic equipment, making it a product-focused rule. REACH is a broader regulation covering the registration and risk management of thousands of chemical substances across all industries, making it a chemical-focused rule.

- Why is China RoHS compliance more complex than EU RoHS? China RoHS often requires mandatory third-party testing and certification by accredited labs for products listed in its official catalogue, a significant departure from the EU’s self-declaration model, which adds cost and time to market entry.

- What is the Digital Product Passport (DPP)? The DPP is a forthcoming EU requirement under the ESPR that will mandate a digital record of a product’s lifecycle data – including materials, substances, repairability, and circularity information – accessible via a data carrier like a QR code.

Frequently Asked Questions (FAQ)

- Q: How do we manage component-level compliance across thousands of suppliers?

This is impossible to do manually at scale. The solution lies in a centralized compliance management platform that automates supplier outreach, standardizes data collection (e.g., IPC-1752A), and validates incoming information against a live regulatory database. - Q: Can we rely solely on supplier declarations?

Supplier declarations are your first line of defence, but they aren’t foolproof. A risk-based approach is critical. For high-risk components or new suppliers, you should augment declarations with a strategic third-party testing program to verify the data you receive. - Q: What’s the first step to prepare for the Digital Product Passport?

Start with a data gap analysis. Map out the information the DPP will require against the data you currently collect from your supply chain. This will immediately reveal your blind spots and help you prioritize your supplier engagement and data collection efforts for the next 2-3 years. - Q: Our products are sold globally. How do we prioritize which regulations to focus on first?

Prioritize based on revenue and risk. Identify the markets that represent your highest revenue streams and have the most stringent enforcement. Then, focus on “foundational” regulations like EU RoHS and REACH, as they often form the basis for similar laws in other regions. Finally, layer on unique, high-risk rules like China RoHS or California Prop 65 for those specific markets.

Don’t Just Manage Compliance – Master It

The complexity is overwhelming, but the path forward is clear. Staying ahead of the 2025-2030 compliance curve is no longer about having the biggest library of regulations; it’s about having the most intelligent system to navigate them. It requires moving from reactive checklists to a proactive, integrated framework that protects your revenue, de-risks your supply chain, and turns compliance into a competitive advantage.

When you’re ready to build that framework, explore the C2P platform for comprehensive compliance solutions.

Schedule a complimentary Compliance Strategy Assessment with our experts to map your specific risks and build a resilient framework for the challenges ahead.

Experience the Future of ESG Compliance

The Compliance & Risks Sustainability Platform is available now with a 30-day free trial. Experience firsthand how AI-driven, human-verified intelligence transforms regulatory complexity into strategic clarity.

👉 Start your free trial today and see how your team can lead the future of ESG compliance.

The future of compliance is predictive, verifiable, and strategic. The only question is: Will you be leading it, or catching up to it?

Six Months of Research, Done in 60 Seconds

Cut through ESG chaos and act with clarity. Try C&R Sustainability Free.