The Ultimate Regulatory Crosswalk: Mapping RoHS, REACH, POPs, and TSCA to Avoid Costly Fines

THIS BLOG WAS WRITTEN BY THE COMPLIANCE & RISKS MARKETING TEAM TO INFORM AND ENGAGE. HOWEVER, COMPLEX REGULATORY QUESTIONS REQUIRE SPECIALIST KNOWLEDGE. TO GET ACCURATE, EXPERT ANSWERS, PLEASE CLICK “ASK AN EXPERT.”

The compliance challenge is overwhelming. You’ve got a spreadsheet open for RoHS, another for REACH SVHCs, a PDF of the latest POPs updates, and you’re trying to decipher an EPA notification about TSCA. Each one is a universe of its own, with different rules, different substances, and different reporting deadlines. And in the back of your mind is the nagging fear that a single misstep, a single overlapping chemical you missed, could bring a product launch to a grinding halt.

Or worse.

A single violation of the Toxic Substances Control Act (TSCA) can result in penalties exceeding $49,000 per violation, per day. And for emerging substances like PFAS, that figure can climb even higher. This isn’t just about ticking boxes; it’s about protecting your revenue, your supply chain, and your brand’s reputation.

The core problem is that these regulations don’t exist in tidy, separate silos. They overlap, conflict, and create a tangled web of compliance obligations. You aren’t just managing four lists; you’re managing a complex, four-dimensional risk matrix. You need a unified regulatory crosswalk.

We’re going to map the critical overlaps between RoHS, REACH, POPs, and TSCA, focusing on the shared substances, enforcement conflicts, and emerging threats that create the most risk for your business.

Table of Contents

- Key Takeaways: Your Compliance Cheat Sheet

- The Unified Substance Crosswalk: A Single Source of Truth

- Decoding the Enforcement Maze: Why These Frameworks Don’t Play Nice

- The New Front Lines: Where Compliance Battles Will Be Fought in 2025

- The Real Cost of Getting It Wrong

- From Chaos to Control: How to Automate Your Cross-Framework Compliance

- Frequently Asked Questions

Key Takeaways: Your Compliance Cheat Sheet

For those who need the answer now, here’s the bottom line:

- What is a regulatory crosswalk? It’s a mapping exercise that identifies how a single chemical substance is treated across multiple regulations (like RoHS, REACH, POPs, and TSCA), revealing overlapping restrictions, conflicting reporting requirements, and potential compliance gaps.

- Why is this so critical? Non-compliance isn’t a slap on the wrist. TSCA violations alone can cost over $49,000 per day. A crosswalk prevents you from being compliant with one regulation while violating another with the same product.

- What are the biggest conflicts? The key conflicts arise from legal structure (EU Regulations vs. Directives vs. US Acts) and reporting level (REACH/SCIP’s “article-level” reporting vs. RoHS’s “homogeneous material” standard).

- What are the top emerging threats? The SCIP database requirement for products sold in the EU and the global crackdown on PFAS are the two most urgent, cross-regulatory challenges facing compliance teams today. They require unprecedented levels of supply chain data transparency.

The Unified Substance Crosswalk: A Single Source of Truth

Let’s start with the most practical tool. The real challenge is tracking a substance that appears on multiple lists. Think of Decabromodiphenyl ether (DecaBDE). It’s a flame retardant that has been widely used in electronics and textiles. It’s also a perfect example of regulatory overlap.

- It’s restricted under the EU RoHS Directive.

- It’s listed as a Substance of Very High Concern (SVHC) under EU REACH.

- It’s regulated as a Persistent Organic Pollutant under the global Stockholm Convention (POPs).

- And it’s one of the five persistent, bioaccumulative, and toxic (PBT) chemicals subject to risk management rules under US TSCA.

If you only check the RoHS list, you miss the broader obligations under REACH, the global phase-out under POPs, and the stringent restrictions in the US. This is where manual tracking breaks down.

A true crosswalk matrix gives you a single view of your risk. While a comprehensive, live database is the only way to manage this long-term, here’s a snapshot of what this cross-mapping looks like for a few common substances.

| Substance Name | CAS Number | RoHS Status (EU) | REACH Status (EU) | POPs Status (Global) | TSCA Status (US) |

|---|---|---|---|---|---|

| Lead (Pb) | 7439-92-1 | Restricted (≤0.1%) | SVHC (Candidate List) | Not Listed | Action Level for Paint |

| Cadmium (Cd) | 7440-43-9 | Restricted (≤0.01%) | SVHC, Annex XVII Restricted | Not Listed | Regulated in Batteries |

| DEHP | 117-81-7 | Restricted (≤0.1%) | SVHC, Auth. List (Annex XIV) | Not Listed | Action Plan, PBT concern |

| DecaBDE | 1163-19-5 | Restricted (≤0.1%) | SVHC, Annex XVII Restricted | Annex A (Elimination) | PBT Rule, Restricted |

| PFOA | 335-67-1 | Not listed | SVHC (Candidate List) | Annex A (Elimination) | PBT Reporting |

This table just scratches the surface. The ECHA Candidate List of SVHCs has over 200 entries, the TSCA Inventory has thousands, and these lists are updated constantly. This isn’t a one-time project; it’s a continuous monitoring function. A static blog post or spreadsheet becomes outdated the moment a new substance is proposed for inclusion.

Decoding the Enforcement Maze: Why These Frameworks Don’t Play Nice

Understanding which substances are on which list is only half the battle. The real headache – and the source of hidden risk – comes from the fundamental differences in how these laws are structured and enforced.

More Than Acronyms: Regulation vs. Directive vs. Act

You’ve heard the terms, but what do they actually mean for your day-to-day operations? Honestly, everything.

- Regulation (like REACH): Think of this as a single, uniform law applied directly across the entire EU. When the European Commission passes a REACH update, it becomes law in Germany, France, and Poland simultaneously without any national government intervention. There’s one rulebook for everyone. This simplifies things but also means compliance is rigid and non-negotiable.

- Directive (like RoHS): This is different. A Directive sets a goal that all EU member states must achieve, but it leaves it up to each country to write its own national laws to meet that goal. The result? You can have 27 slightly different versions of RoHS. Germany’s enforcement might focus on documentation, while Italy’s might prioritize market surveillance and product testing. This nuance means you can be compliant in one country but at risk in another, adding a painful layer of complexity.

- Act (like TSCA): This is a federal law passed by the U.S. Congress and enforced by a specific agency – in this case, the Environmental Protection Agency (EPA). Under reformed TSCA, manufacturers bear greater responsibility to provide chemical data and information. For downstream users of those chemicals, this means the EPA has significant authority to demand data, restrict use, and levy those eye-watering fines.

The operational takeaway? You can’t use a one-size-fits-all compliance strategy. Your process for demonstrating REACH compliance (centralized, data-heavy reporting to ECHA) is fundamentally different from navigating RoHS (managing varied national enforcement) or responding to a TSCA data call from the EPA.

The Reporting Mismatch: Why “Article” and “Homogeneous Material” Are in Conflict

Here’s where the technical details really create problems. The regulations define the “thing” you’re reporting on differently.

Imagine a single coated screw in your product.

- Under RoHS, compliance is measured at the “homogeneous material” level. This means you’d have to test the screw’s metal alloy separately from its anti-corrosion coating. If the coating contains excessive lead, the screw fails, and by extension, your entire product is non-compliant.

- Under REACH and the SCIP database, the rules often apply at the “article” level. An article is defined as an object given a special shape, surface, or design that determines its function to a greater degree than its chemical composition. That screw is an article. But the laptop casing it’s attached to is also an article. If that screw contains an SVHC above 0.1% of its own weight, you have a duty to report it to the SCIP database.

This creates a massive data management conflict. Your RoHS team is thinking in terms of materials, while your REACH team is thinking in terms of components and sub-assemblies. The data you collect for one isn’t sufficient for the other, forcing you to go back to your suppliers multiple times with different, confusing requests. It’s inefficient, expensive, and a major source of compliance errors.

The New Front Lines: Where Compliance Battles Will Be Fought

The regulatory landscape never sits still. Two developments are dominating the conversation right now and creating urgent, cross-framework challenges: the SCIP database and the explosion of PFAS regulations.

The SCIP Database Dilemma: Radical Transparency Is Here

Launched by the European Chemicals Agency (ECHA), the SCIP (Substances of Concern In articles as such or in complex objects (Products)) database is a game-changer. It’s a publicly accessible database of products sold in the EU that contain SVHCs from the REACH Candidate List.

If your product contains an article with an SVHC concentration over 0.1% w/w, you are legally required to submit detailed information to this database.

Here’s why this is such a challenge:

- Unprecedented Granularity: You need to know the chemical makeup of every single component – every resistor, every bracket, every O-ring – from a supply chain that can span hundreds of individual companies.

- It’s Not Just About Banning: Unlike RoHS, SCIP isn’t primarily about restricting chemicals. It’s about creating transparency for waste operators and consumers. The goal is to facilitate a circular economy by identifying hazardous substances before a product is recycled or thrown away.

- Operational Burden: For complex products, this means creating thousands of individual SCIP notifications. It’s a monumental data collection and management task that is simply impossible to handle with spreadsheets. You need a robust product compliance solution to manage the data flow from your supply chain.

PFAS: The “Forever Chemical” Uniting Global Regulators

If there’s one family of chemicals that demonstrates the need for a regulatory crosswalk, it’s Per- and Polyfluoroalkyl Substances (PFAS). These “forever chemicals” are used in everything from non-stick coatings and firefighting foam to semiconductors and water-resistant fabrics.

And regulators around the world are cracking down. Hard.

- In the EU, several PFAS are already on the REACH Candidate List, with a broader proposal underway to restrict thousands more.

- In the US, the EPA is using its authority under TSCA to require reporting and testing for PFAS and has designated two of the most common – PFOA and PFOS – as hazardous substances.

- Individual US States like Maine and California have enacted their own aggressive PFAS phase-out laws that often go beyond federal requirements.

- Globally, certain PFAS are restricted under the Stockholm Convention (POPs).

The message is clear: if you aren’t proactively tracking and phasing out PFAS in your products and supply chain, you are exposing your business to significant future risk across multiple jurisdictions. This is no longer just a European or American issue; it’s a global compliance imperative.

The Real Cost of Getting It Wrong

We started with the $49,000-per-day TSCA fine, but the financial risk goes far beyond that. A single compliance failure could lead to serious consequences for your business:

- Forced Product Recalls: Pulling a product from the market is an expensive, logistical nightmare that damages customer trust.

- Blocked Shipments: Customs officials in the EU and elsewhere are actively enforcing these regulations. A non-compliant product can be stopped at the border, disrupting your entire distribution network.

- Costly Rework: Discovering a non-compliant component late in the design cycle can mean scrapping tools, re-sourcing materials, and delaying your launch by months.

- Reputational Damage: Being labeled as a company that sells products with hazardous chemicals is a PR crisis that can have long-lasting effects on your brand.

Investing in a proactive compliance management strategy isn’t a cost center – it’s financial risk insurance.

From Chaos to Control: How to Automate Your Cross-Framework Compliance

Juggling these overlapping regulations manually is no longer a viable strategy. The pace of change is too fast, the data requirements are too complex, and the financial risks are too high.

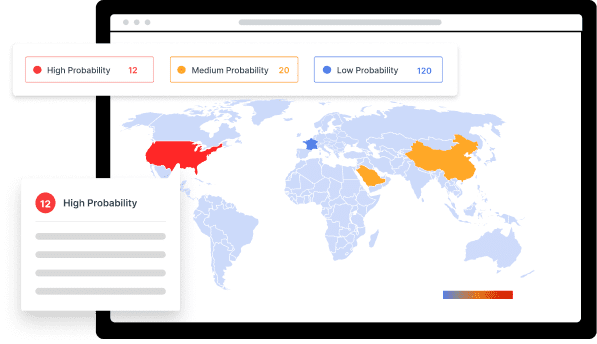

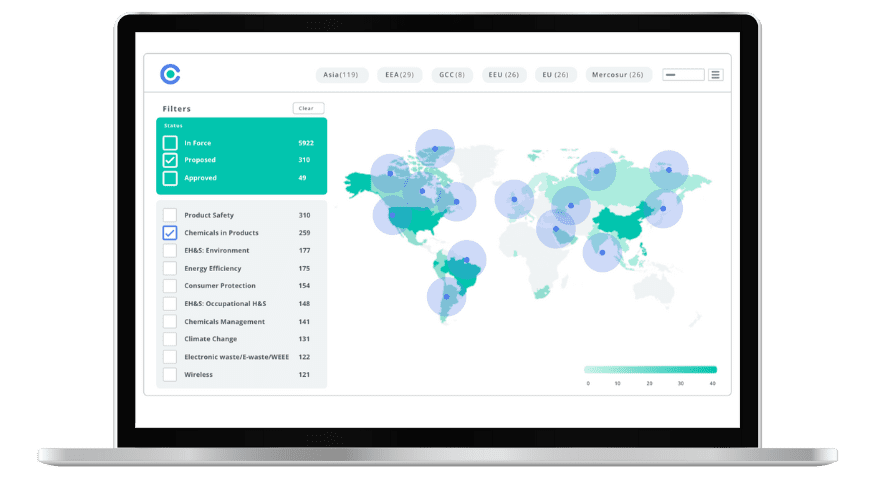

The only sustainable path forward is to move from reactive, spreadsheet-based tracking to a centralized, automated system. A robust regulatory compliance platform like C2P is designed to act as your single source of truth.

Think about what that means:

- A Living Crosswalk: Instead of a static table, you get a live-updated database that maps substances across global regulations in real time. When a new SVHC is proposed, you know immediately.

- Automated Data Collection: Streamline the process of gathering compliance data from your suppliers, validating it, and rolling it up to the product level.

- Conflict Resolution: The system automatically flags the conflicts between reporting requirements (like Article vs. Homogeneous Material) and provides the tools to manage both.

- Proactive Alerts: Get ahead of the curve with alerts on emerging regulations like PFAS restrictions, giving your engineering teams time to design them out of your products.

This isn’t about simply buying software. It’s about fundamentally changing your approach to compliance – from a reactive, risk-prone scramble to a proactive, controlled business process.

Frequently Asked Questions

- Q: Can’t I just manage this with a really good spreadsheet?

For a very simple product with a handful of components, maybe. But for any complex product, spreadsheets become a massive liability. They are prone to human error, can’t be updated in real time, offer no audit trail, and make it impossible to manage the data requests for thousands of parts from hundreds of suppliers. - Q: How often do these regulatory lists actually change?

Constantly. The REACH Candidate List is typically updated twice a year. TSCA rules are continuously being proposed and finalized by the EPA. New POPs are added to the Stockholm Convention regularly. Relying on a manual process guarantees you will fall behind. - Q: We’re a small company. Do we really need to worry about all four of these?

It depends entirely on where you sell your products. If you sell into the EU, REACH and RoHS are mandatory. If you sell into the US, TSCA applies. And because POPs is a global treaty, its restrictions can impact your supply chain regardless of your final market. Market access is directly tied to compliance. - Q: What’s the single most important first step we should take?

Start with a product risk assessment. Identify which of your products are sold in which markets, and map them to the relevant regulations. This will help you prioritize your biggest compliance gaps. From there, the next critical step is getting visibility into your supply chain data—you can’t manage what you can’t measure.

Ready to stop juggling regulations and build a resilient compliance program? A unified view of your obligations is the first step.

Schedule a consultation with our experts to see how C2P can automate your global regulatory crosswalk and protect your business from costly compliance failures.

Experience the Future of ESG Compliance

The Compliance & Risks Sustainability Platform is available now with a 30-day free trial. Experience firsthand how AI-driven, human-verified intelligence transforms regulatory complexity into strategic clarity.

👉 Start your free trial today and see how your team can lead the future of ESG compliance.

The future of compliance is predictive, verifiable, and strategic. The only question is: Will you be leading it, or catching up to it?

Simplify Corporate Sustainability Compliance

Six months of research, done in 60 seconds. Cut through ESG chaos and act with clarity. Try C&R Sustainability Free.