Communicating GHS Compliance Across the Supply Chain: A Complete Guide to Downstream User Responsibilities and Documentation Workflows

THIS BLOG WAS WRITTEN BY THE COMPLIANCE & RISKS MARKETING TEAM TO INFORM AND ENGAGE. HOWEVER, COMPLEX REGULATORY QUESTIONS REQUIRE SPECIALIST KNOWLEDGE. TO GET ACCURATE, EXPERT ANSWERS, PLEASE CLICK “ASK AN EXPERT.”

Supply chain GHS compliance isn’t just about having the right labels and safety data sheets – it’s about creating a seamless information flow that protects every worker, consumer, and environment that encounters chemical products. With over 90 countries now implementing GHS standards, the complexity of maintaining consistent hazard communication across global supply chains has reached unprecedented levels.

This comprehensive guide explores how downstream users can fulfill their compliance responsibilities while establishing documentation workflows that ensure consistent hazard communication from manufacturer to end user. Whether you’re managing supplier declarations, distributor obligations, or international transport documentation, understanding these interconnected processes is critical for maintaining regulatory compliance and operational efficiency.

Table of Contents

- Understanding GHS Supply Chain Communication

- Downstream User Responsibilities in GHS Compliance

- Disclosure Rules and Information Requirements

- Building Effective Documentation Workflows

- Supplier Declarations and Upstream Communication

- Distributor Obligations and Chain Management

- Importer Compliance Strategies

- B2B Transport Documentation Practices

- Technology Solutions for Supply Chain Communication

- Common Compliance Challenges and Solutions

- Frequently Asked Questions

- Next Steps for GHS Supply Chain Compliance

Understanding GHS Supply Chain Communication

The Globally Harmonized System creates a standardized approach to chemical hazard communication, but implementing this standard across complex supply chains requires careful coordination between multiple parties. Each entity in the supply chain – from raw material suppliers to distributors to end users – plays a crucial role in maintaining information integrity.

Supply chain GHS communication operates on three fundamental principles: information consistency, responsibility clarity, and documentation traceability. When properly implemented, these principles create a robust framework that protects workers and ensures regulatory compliance at every stage of the chemical lifecycle.

The Multi-Jurisdictional Challenge

Supply chains rarely operate within single regulatory jurisdictions, creating unique compliance challenges. A chemical manufactured in one country, distributed through another, and used in a third must comply with the GHS requirements of all relevant jurisdictions. This complexity increases exponentially when considering that GHS implementation varies between countries, with differences in classification criteria, labeling requirements, and safety data sheet formats.

Understanding these jurisdictional differences is essential for downstream users who must ensure their communication practices meet the most stringent requirements applicable to their operations. This often means adopting a “highest common denominator” approach to compliance, where companies implement the strictest requirements across their entire supply chain to ensure consistent protection levels.

Downstream User Responsibilities in GHS Compliance

Downstream users occupy a critical position in the GHS supply chain, serving as both recipients of hazard information from suppliers and providers of information to their customers or end users. This dual role creates specific responsibilities that extend beyond simple information relay.

Information Verification and Validation

Downstream users must verify the accuracy and completeness of hazard information received from suppliers. This involves reviewing safety data sheets for completeness, ensuring classification consistency with product composition, and confirming that labeling elements align with GHS requirements. When discrepancies are identified, downstream users have a responsibility to engage with suppliers to resolve these issues before passing products down the supply chain.

The verification process requires technical expertise to assess classification accuracy, particularly for mixtures where classification may depend on concentration thresholds or synergistic effects. Downstream users must maintain competency in GHS classification principles or engage qualified personnel to perform these assessments.

Information Enhancement and Addition

In many cases, downstream users must enhance or add to the hazard information received from suppliers. This occurs when products are repackaged, relabeled, or when additional use information is developed. Any modifications to hazard communication materials must maintain compliance with GHS requirements while ensuring that new information doesn’t contradict or undermine upstream hazard assessments.

Common scenarios requiring information enhancement include:

Repackaging Operations: When products are transferred to different containers, new labels must be prepared that maintain GHS compliance while reflecting the new packaging format. This includes ensuring proper label sizing, readability, and durability requirements are met.

Use-Specific Applications: Downstream users may develop additional safety recommendations based on specific use scenarios or customer requirements. These additions must complement, not contradict, the original hazard information and should be clearly identified as downstream user additions.

Language Localization: Products moving across language boundaries require translation of hazard information. Downstream users responsible for translation must ensure technical accuracy while maintaining the integrity of hazard communication messages.

Due Diligence and Supply Chain Oversight

Downstream users have an ongoing responsibility to monitor their supply chain for compliance issues and changes that may affect hazard information. This includes establishing supplier qualification processes, conducting periodic compliance audits, and maintaining systems to track regulatory changes that may affect product classifications or communication requirements.

Effective due diligence programs include regular supplier assessments, contract provisions requiring compliance notification, and procedures for managing non-conforming products. These systems help identify potential compliance issues before they impact downstream operations or end users.

Disclosure Rules and Information Requirements

GHS disclosure requirements create specific obligations for information sharing across the supply chain. Understanding these requirements is essential for maintaining compliance while protecting legitimate business interests such as confidential business information.

Mandatory Disclosure Elements

Certain information elements must be disclosed regardless of confidentiality concerns. These mandatory disclosures include all information necessary for safe handling, storage, and use of chemical products. Under GHS requirements, the following elements must always be disclosed:

Physical and Health Hazards: Complete hazard classification information, including all applicable hazard categories and severity levels, must be communicated across the supply chain. This information cannot be withheld on confidentiality grounds as it directly impacts worker safety and environmental protection.

Emergency Response Information: Information necessary for emergency response, including first aid measures, firefighting procedures, and accidental release measures, must be fully disclosed. Emergency responders require complete hazard information to protect themselves and the public during incidents.

Handling Precautions: Safe handling, storage, and disposal information must be communicated to ensure proper risk management throughout the chemical lifecycle. This includes personal protective equipment requirements, engineering controls, and incompatibility warnings.

Confidential Business Information Protection

While safety information must be disclosed, GHS systems provide mechanisms for protecting legitimate confidential business information (CBI). These protections allow companies to maintain competitive advantages while fulfilling safety communication obligations.

Chemical Identity Protection: In many jurisdictions, specific chemical identities may be protected through generic names or chemical classes, provided this approach doesn’t compromise safety communication. However, enough information must be disclosed to enable proper risk assessment and management.

Concentration Ranges: Instead of exact concentrations, companies may use concentration ranges that provide sufficient information for hazard assessment while protecting formulation details. These ranges must be narrow enough to enable accurate classification and risk management.

Trade Name Protection: Proprietary mixture names and formulation codes can typically be protected, provided that hazard information is fully communicated through other means such as generic descriptions and hazard classifications.

Information Update Requirements

Supply chain participants must establish systems for communicating information changes throughout the chain. This includes both routine updates based on new scientific information and urgent notifications for significant hazard discoveries or classification changes.

Update notification systems must address timing requirements, communication methods, and documentation needs. Many jurisdictions specify maximum timeframes for communicating significant changes, requiring robust change management processes to ensure compliance.

Building Effective Documentation Workflows

Documentation workflows form the backbone of supply chain GHS compliance, ensuring that hazard information flows seamlessly from suppliers to end users while maintaining traceability and compliance verification. Effective workflows balance automation with human oversight to create efficient yet reliable systems.

Core Documentation Requirements

Supply chain GHS documentation must satisfy multiple regulatory requirements while supporting operational efficiency. The core documentation elements include:

Safety Data Sheets Management: Systems must ensure that current, accurate SDSs are available to all relevant personnel. This includes version control, distribution management, and archival procedures that maintain historical records for regulatory and liability purposes.

Labeling Documentation: Complete records of labeling decisions, including classification rationale, pictogram selection, and hazard statement determination. This documentation supports consistency across packaging operations and provides evidence of compliance due diligence.

Supply Chain Communication Records: Documentation of all hazard information exchanges, including supplier notifications, customer communications, and regulatory reporting. These records demonstrate compliance with disclosure requirements and support incident investigation if needed.

Process Integration and Cross-Functional Coordination

Effective GHS workflows integrate with existing business processes to minimize disruption while ensuring compliance. This integration requires coordination across multiple functions including procurement, operations, quality assurance, and sales.

Procurement Integration: Purchase order systems should capture GHS compliance requirements and ensure that suppliers understand their communication obligations. This includes specification development, supplier qualification procedures, and contract management processes.

Operations Coordination: Manufacturing and distribution operations must receive timely hazard information updates and have procedures for implementing changes. This includes inventory management, production planning, and quality control integration.

Sales and Distribution Alignment: Customer-facing teams must understand GHS requirements and have access to current hazard information for customer communication. This includes order processing, shipping documentation, and customer service support.

Quality Management and Continuous Improvement

Documentation workflows must include quality management elements that ensure ongoing compliance and identify opportunities for improvement. These systems should monitor compliance metrics, track non-conformances, and drive corrective actions.

Quality indicators for GHS workflows include information accuracy rates, update distribution timeliness, and customer compliance feedback. Regular assessment of these metrics helps identify system weaknesses and optimization opportunities.

Supplier Declarations and Upstream Communication

Supplier declarations serve as the foundation for downstream GHS compliance, providing the hazard information and compliance commitments necessary for effective supply chain management. Establishing clear expectations and robust verification processes is essential for maintaining information quality and compliance assurance.

Declaration Content and Format Requirements

Effective supplier declarations must provide comprehensive hazard information while addressing specific downstream user needs. Standard declaration elements should include:

Complete Hazard Classification: Suppliers must provide full GHS classification information, including specific hazard categories, severity levels, and supporting rationale. This information enables downstream users to verify classification accuracy and make informed risk management decisions.

Regulatory Status Confirmation: Declarations should confirm compliance with all applicable GHS requirements in relevant jurisdictions. This includes registration status, notification compliance, and any restrictions or special conditions affecting product use or distribution.

Change Notification Commitments: Suppliers must commit to timely notification of any changes affecting hazard classification, regulatory status, or safety recommendations. Clear timeframes and communication methods should be specified to ensure reliable information flow.

Supplier Qualification and Assessment

Robust supplier qualification processes help ensure that upstream partners have the capability and commitment necessary for GHS compliance. These assessments should evaluate both technical competency and quality system adequacy.

Technical Competency Assessment: Suppliers must demonstrate adequate expertise in GHS classification, safety data sheet preparation, and regulatory compliance. This may include staff qualifications, training records, and system capabilities.

Quality System Evaluation: Supplier quality systems should include procedures for maintaining information accuracy, managing changes, and ensuring compliance consistency. Regular audits or assessments help verify ongoing system effectiveness.

Performance Monitoring: Ongoing supplier performance monitoring should track compliance metrics such as information accuracy, update timeliness, and customer service responsiveness. Performance issues should trigger corrective action processes and, if necessary, supplier development initiatives.

Communication Protocol Development

Clear communication protocols ensure that hazard information flows efficiently between suppliers and downstream users while minimizing misunderstandings and compliance gaps. These protocols should address both routine information exchange and urgent notifications.

Standard Communication Channels: Established channels for routine information exchange, including safety data sheet distribution, regulatory updates, and technical inquiries. These channels should be reliable, traceable, and accessible to relevant personnel.

Emergency Communication Procedures: Special procedures for urgent hazard information updates, including significant classification changes, new regulatory requirements, or safety concerns. These procedures should ensure rapid communication while maintaining information accuracy.

Documentation Requirements: Clear documentation standards for all supplier communications, including record retention, filing systems, and accessibility requirements. Proper documentation supports compliance verification and incident investigation if needed.

Distributor Obligations and Chain Management

Distributors play a unique role in GHS supply chain communication, often serving as intermediaries between manufacturers and end users while also performing value-added services such as repackaging, labeling, or product mixing. This position creates specific compliance obligations and operational challenges.

Core Distributor Responsibilities

Distributors must fulfill multiple compliance roles while maintaining operational efficiency and customer service quality. These responsibilities include:

Information Relay and Maintenance: Distributors must ensure that complete, accurate hazard information reaches their customers without degradation or loss. This includes maintaining current safety data sheets, preserving labeling integrity, and communicating any updates or changes received from suppliers.

Product Integrity Assurance: Physical handling and storage practices must maintain product quality and prevent contamination that could affect hazard characteristics. This includes proper storage conditions, handling procedures, and quality control measures.

Customer Communication Support: Distributors often serve as the primary point of contact for customer questions about product safety and compliance. This requires maintaining technical expertise and having access to complete hazard information and supplier support.

Value-Added Service Compliance

When distributors perform value-added services, they may assume additional GHS compliance responsibilities similar to those of manufacturers. These services create specific compliance challenges:

Repackaging Operations: Transferring products to different containers requires new labeling that maintains GHS compliance while reflecting the new packaging format. This includes proper label design, placement, and durability testing.

Product Mixing and Blending: Combining different chemical products creates new mixture classification requirements. Distributors performing these operations must have the technical capability to assess mixture hazards and prepare appropriate hazard communication materials.

Custom Labeling and Documentation: Providing customer-specific labeling or documentation requires maintaining compliance across multiple formats while ensuring consistency with underlying hazard information.

Multi-Customer Management

Distributors typically serve diverse customer bases with varying compliance requirements and technical capabilities. Managing this diversity while maintaining consistent compliance standards requires sophisticated systems and processes.

Customer Segmentation and Service: Different customer types (large industrial users, small businesses, research institutions) may have different information needs and compliance capabilities. Distributors must tailor their communication approaches while maintaining compliance consistency.

Regulatory Variation Management: Customers in different jurisdictions may be subject to different GHS implementation requirements. Distributors must understand these variations and ensure their communication practices meet all applicable requirements.

Training and Support Services: Many distributor customers require ongoing support for GHS compliance implementation. Distributors may provide training services, technical consultation, and compliance assistance as value-added services.

Importer Compliance Strategies

Importers face unique GHS compliance challenges, often serving as the first point of regulatory responsibility for products entering new jurisdictions. This position requires comprehensive understanding of both origin and destination regulatory requirements, along with systems for ensuring compliance across regulatory boundaries.

Regulatory Navigation and Harmonization

Import operations must navigate differences between GHS implementation across jurisdictions while ensuring compliance with destination requirements. This navigation requires sophisticated regulatory intelligence and compliance management systems.

Jurisdiction-Specific Requirements: Different countries implement GHS with variations in classification criteria, labeling requirements, and safety data sheet formats. Importers must understand these differences and ensure their products comply with destination requirements rather than origin requirements.

Classification Harmonization: When products are classified differently in origin and destination jurisdictions, importers must determine which classification applies and whether products require reclassification for the destination market. This may require technical assessment by qualified personnel.

Documentation Adaptation: Import documentation, including safety data sheets and labels, may require modification to meet destination requirements. This adaptation must maintain technical accuracy while ensuring regulatory compliance.

Supply Chain Coordination Across Borders

International supply chains create additional coordination challenges, including language barriers, time zone differences, and varying business practices. Effective importer strategies address these challenges while maintaining compliance integrity.

Supplier Relationship Management: International suppliers may have limited understanding of destination regulatory requirements. Importers must provide clear specifications, ongoing guidance, and performance feedback to ensure compliance.

Communication System Development: Systems for international communication must account for language differences, cultural factors, and technical capability variations. This may include translation services, cultural adaptation, and technical support.

Change Management Processes: Regulatory changes in destination jurisdictions must be communicated to international suppliers with sufficient lead time for implementation. This requires proactive regulatory monitoring and supplier communication systems.

Documentation and Record-Keeping

Import operations require extensive documentation to demonstrate compliance with both trade and chemical safety regulations. These documentation requirements often exceed those for domestic operations.

Compliance Documentation: Complete records of classification decisions, labeling rationale, and regulatory compliance verification. This documentation must be available for regulatory inspection and supports trade clearance processes.

Supply Chain Traceability: Detailed records of product flow from origin to destination, including all handling, storage, and transportation activities. This traceability supports incident investigation and regulatory inquiry response.

Regulatory Correspondence: Records of all communication with regulatory authorities, including pre-import consultations, compliance clarifications, and enforcement correspondence. These records demonstrate good faith compliance efforts and support regulatory relationship management.

B2B Transport Documentation Practices

Transportation of chemical products requires specialized documentation that bridges GHS hazard communication with transport safety requirements. These documentation practices must satisfy multiple regulatory frameworks while ensuring safe handling throughout the transportation chain.

Integration of GHS and Transport Classifications

GHS classification systems often differ from transport classification systems (such as those used for dangerous goods shipping), creating the need for integrated documentation approaches that address both sets of requirements.

Parallel Classification Management: Products may require classification under both GHS and transport regulations, with different hazard categories and communication requirements. Documentation systems must maintain both classifications while ensuring consistency where they overlap.

Shipping Document Preparation: Transport documents must include both GHS hazard information and transport-specific safety data. This integration requires careful attention to format requirements, information priority, and space limitations on standard documents.

Emergency Response Integration: Emergency response information must address both workplace safety (GHS focus) and transport incident response (transport regulation focus). This may require different information emphasis or supplementary documentation for transport scenarios.

Chain of Custody and Information Flow

Transport operations involve multiple parties (shippers, carriers, receivers) who must have access to appropriate hazard information while maintaining information security and confidentiality protection.

Information Access Management: Different parties in the transport chain may need different levels of hazard information. Systems must provide appropriate access while protecting confidential business information and maintaining security requirements.

Hand-off Procedures: Transfer of custody between transport parties must include proper hazard information transfer and acknowledgment. These procedures ensure continued safety awareness and compliance responsibility throughout the transport chain.

Documentation Continuity: Transport documentation must maintain information integrity across multiple handoffs, storage periods, and handling operations. This requires robust document management systems and quality control procedures.

Technology Integration and Automation

Modern transport operations increasingly rely on electronic documentation and automated systems for efficiency and accuracy. GHS compliance systems must integrate with these technologies while maintaining regulatory compliance.

Electronic Documentation: Digital transport documents must maintain the same compliance standards as paper documents while leveraging technology advantages such as real-time updates and automated distribution.

Data Integration: Transport management systems must integrate GHS hazard data with shipping information, routing decisions, and carrier requirements. This integration supports automated compliance checking and optimized transport planning.

Mobile Access and Field Support: Transport personnel need mobile access to hazard information for incident response and routine operations. Mobile systems must provide reliable access while maintaining information security and usability under field conditions.

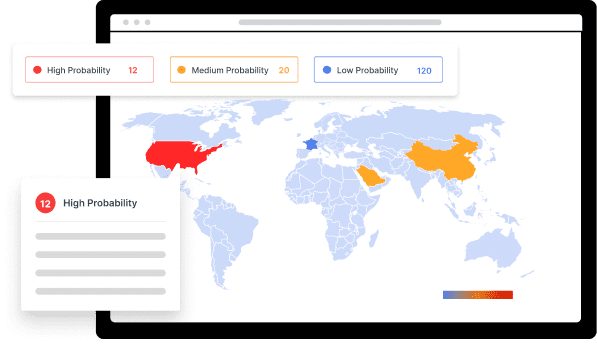

Technology Solutions for Supply Chain Communication

Modern GHS compliance increasingly relies on technology solutions to manage the complexity of global supply chain communication while ensuring accuracy, timeliness, and regulatory compliance. These solutions range from simple database systems to sophisticated platforms that integrate multiple compliance functions.

Integrated Compliance Platforms

Comprehensive technology platforms can streamline GHS compliance by integrating multiple functions into unified systems that support end-to-end supply chain communication.

Centralized Information Management: Platforms that maintain centralized repositories of hazard information, regulatory requirements, and compliance documentation enable consistent communication across complex supply chains while ensuring information accuracy and currency.

Automated Update Distribution: When hazard information changes, automated systems can distribute updates to all affected parties throughout the supply chain, ensuring timely communication while maintaining audit trails of distribution activities.

Multi-Jurisdictional Support: Advanced platforms can maintain jurisdiction-specific compliance requirements and automatically generate appropriate documentation formats for different regulatory environments.

Data Quality and Validation Systems

Technology solutions can significantly improve the accuracy and consistency of GHS information through automated validation and quality control processes.

Classification Validation: Automated systems can check classification consistency, verify hazard category assignments, and identify potential errors or inconsistencies in hazard assessments.

Documentation Quality Control: Automated review of safety data sheets and labels can identify formatting errors, missing information, and compliance deficiencies before documents are distributed.

Regulatory Updates Integration: Systems that automatically incorporate regulatory changes can help ensure ongoing compliance while reducing the manual effort required to maintain current requirements.

Communication and Workflow Automation

Automated workflow systems can streamline routine compliance processes while ensuring that human oversight is applied where needed for technical decisions and quality assurance.

Supplier Communication: Automated systems for supplier onboarding, performance monitoring, and information requests can improve efficiency while maintaining compliance standards.

Customer Notification: When product information changes, automated systems can generate appropriate customer notifications while tracking acknowledgment and implementation status.

Workflow Management: Automated routing of compliance tasks, approvals, and reviews can ensure timely completion while maintaining proper oversight and documentation.

Common Compliance Challenges and Solutions

Supply chain GHS compliance faces recurring challenges that can compromise both regulatory compliance and operational efficiency. Understanding these challenges and implementing proven solutions helps organizations build robust compliance programs that withstand regulatory scrutiny and business pressures.

Information Inconsistency Across the Chain

One of the most persistent challenges in supply chain GHS compliance is maintaining information consistency as products move through multiple parties. Each handler may introduce variations, errors, or omissions that compromise the integrity of hazard communication.

Root Causes: Information inconsistency often stems from inadequate communication systems, insufficient technical expertise, or variations in interpretation of GHS requirements. Different software systems, translation processes, and quality control standards can all contribute to information drift.

Solution Framework: Establishing standardized information formats, implementing validation checkpoints, and maintaining centralized information sources can significantly reduce inconsistency issues. Regular auditing of information flow and feedback mechanisms help identify and correct problems before they propagate throughout the supply chain.

Technology Support: Automated validation systems can check for common consistency problems such as mismatched classifications, incomplete safety data sheets, or labeling discrepancies. These systems can flag issues for human review while maintaining operational efficiency.

Resource and Expertise Limitations

Many supply chain participants, particularly smaller companies, struggle with limited resources and expertise for GHS compliance. This challenge is particularly acute for distributors and importers who must understand complex regulatory requirements without the technical infrastructure of large manufacturers.

Capacity Building: Organizations can address resource limitations through targeted training programs, shared service arrangements, or outsourced compliance functions. Industry associations and regulatory agencies often provide guidance documents and training resources that can help build internal capability.

Strategic Partnerships: Collaboration with suppliers, customers, or third-party service providers can help share compliance resources and expertise. These partnerships can provide access to specialized knowledge while distributing costs across multiple organizations.

Scalable Solutions: Technology solutions that can grow with business needs help smaller organizations implement effective compliance systems without overwhelming resource requirements. Cloud-based platforms and subscription services often provide cost-effective access to sophisticated compliance capabilities.

Regulatory Change Management

The dynamic nature of chemical regulations creates ongoing challenges for maintaining current compliance across global supply chains. Regulatory changes may affect classification requirements, communication formats, or disclosure obligations with varying implementation timelines.

Change Monitoring Systems: Proactive monitoring of regulatory developments enables organizations to prepare for changes before they take effect. This includes subscription to regulatory update services, participation in industry associations, and maintenance of relationships with regulatory authorities.

Impact Assessment Processes: When regulatory changes are identified, systematic impact assessment helps determine which products, processes, and customers are affected. This assessment supports priority setting and resource allocation for implementation activities.

Implementation Planning: Effective change management requires coordinated implementation across the supply chain, including supplier notification, system updates, and customer communication. Clear timelines, responsibility assignments, and progress tracking help ensure successful implementation.

Multi-Jurisdictional Complexity

Operating across multiple regulatory jurisdictions creates exponential complexity as organizations must understand and comply with varying requirements while maintaining operational efficiency.

Regulatory Intelligence: Comprehensive understanding of jurisdictional differences requires sophisticated regulatory intelligence capabilities. This may include legal consultation, regulatory affairs expertise, or subscription to specialized information services.

Harmonization Strategies: While complete harmonization may not be possible, organizations can often identify common approaches that satisfy multiple jurisdictions. This “highest common denominator” approach can simplify operations while ensuring comprehensive compliance.

Local Partnership: Establishing relationships with local partners who understand regional requirements can provide essential expertise while supporting market access. These partnerships may include distributors, consultants, or legal advisors with specific jurisdictional expertise.

Frequently Asked Questions

- Q: What are the key differences between upstream and downstream GHS responsibilities?

Upstream parties (manufacturers, importers) have primary responsibility for hazard classification, safety data sheet preparation, and initial labeling. They must conduct hazard assessments, determine appropriate classifications, and prepare comprehensive hazard communication materials. Downstream parties (distributors, users) have responsibility for maintaining information integrity, ensuring proper communication to their customers, and may have additional responsibilities if they modify products or packaging. They must verify information accuracy and enhance it when necessary based on their specific operations or customer needs. - Q: How do confidentiality protections work under GHS requirements?

GHS systems generally allow protection of specific chemical identities and exact formulations while requiring disclosure of all information necessary for safe handling. Companies can use generic names, concentration ranges, and trade name protection mechanisms provided that workers and emergency responders have sufficient information for safety purposes. The key principle is that safety information cannot be withheld on confidentiality grounds. If protecting specific identities compromises safety communication, full disclosure is required. Many jurisdictions provide formal confidential business information procedures that balance these competing interests. - Q: What documentation must be maintained for GHS supply chain compliance?

Essential documentation includes current safety data sheets, labeling records with classification rationale, supplier communications and declarations, customer notification records, training records, and regulatory correspondence. Documentation must demonstrate due diligence in information verification, timely communication of changes, and proper implementation of safety recommendations. Record retention periods vary by jurisdiction but typically range from 3-30 years. Electronic records are generally acceptable provided they maintain integrity, accessibility, and security appropriate for regulatory requirements. - Q: How should companies handle GHS compliance when operating across multiple jurisdictions?

Multi-jurisdictional compliance requires understanding the specific GHS implementation in each relevant jurisdiction, as requirements may vary in classification criteria, labeling formats, and safety data sheet content. Companies often adopt a “highest common denominator” approach, implementing the most stringent requirements across their operations to ensure comprehensive compliance. Key strategies include maintaining regulatory intelligence capabilities, establishing local expertise or partnerships, and implementing flexible systems that can accommodate jurisdictional variations while maintaining operational efficiency. - Q: What role does technology play in modern GHS supply chain compliance?

Technology solutions can significantly improve compliance efficiency and accuracy through automated information validation, centralized data management, and streamlined communication processes. Modern platforms can integrate multiple compliance functions, provide real-time regulatory updates, and support global operations with jurisdiction-specific requirements. However, technology must be implemented thoughtfully with appropriate human oversight for technical decisions, quality assurance, and regulatory interpretation. The most effective approaches combine technological efficiency with expert judgment and stakeholder communication. - Q: How should companies prepare for regulatory changes affecting GHS requirements?

Effective change management requires proactive regulatory monitoring, systematic impact assessment, and coordinated implementation planning. Companies should establish relationships with regulatory agencies, participate in industry associations, and subscribe to regulatory update services to ensure early awareness of pending changes. When changes are identified, comprehensive impact assessment helps determine affected products, processes, and stakeholders. Implementation planning should include supplier notification, system updates, staff training, and customer communication with appropriate timelines for compliance achievement.

Next Steps for GHS Supply Chain Compliance

Implementing effective GHS supply chain compliance requires systematic planning, stakeholder coordination, and ongoing management to ensure both regulatory compliance and operational efficiency. Organizations serious about building robust compliance programs should consider a phased approach that addresses immediate requirements while building long-term capability.

Immediate Assessment and Implementation

Begin with a comprehensive assessment of current compliance status, identifying gaps in information flow, documentation, or stakeholder coordination. This assessment should evaluate both internal processes and supply chain partner capabilities to understand the full scope of compliance requirements.

Priority implementation areas typically include establishing reliable supplier communication, ensuring current safety data sheet availability, and implementing basic change management processes. These foundational elements support ongoing compliance while providing a platform for more sophisticated capabilities.

Long-term Strategic Development

Sustainable GHS compliance requires strategic investment in capabilities that can adapt to changing regulatory requirements and business conditions. This includes technology infrastructure, staff expertise development, and stakeholder relationship management that support long-term success.

Organizations should consider how GHS compliance integrates with broader risk management, sustainability, and operational excellence initiatives. This integration can create synergies that improve both compliance effectiveness and business performance.

Building Competitive Advantage

Leading organizations view GHS compliance not just as a regulatory requirement but as a competitive advantage that demonstrates commitment to safety, quality, and stakeholder protection. Effective compliance programs can differentiate companies in the marketplace while reducing operational risks and costs.

The complexity of global GHS compliance creates opportunities for organizations that invest in sophisticated capabilities and stakeholder relationships. These investments can provide competitive advantages through improved efficiency, reduced risk exposure, and enhanced customer confidence.

Ready to transform your GHS supply chain compliance from a regulatory burden into a competitive advantage? The path forward requires expertise, technology, and strategic planning that aligns with your specific operational requirements and stakeholder needs. Contact our compliance specialists to explore how comprehensive regulatory intelligence and automated compliance management can streamline your supply chain communication while ensuring robust protection for workers and communities throughout your operations.

Stay Ahead Of Regulatory Changes in GHS Supply Chain Compliance

Want to stay ahead of regulatory developments in GHS Supply Chain Compliance?

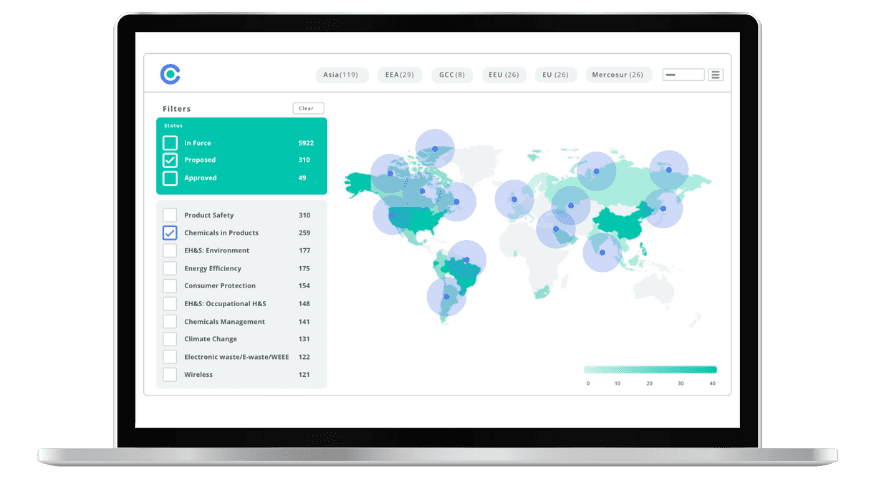

Accelerate your ability to achieve, maintain & expand market access for all products in global markets with C2P – your key to unlocking market access, trusted by more than 300 of the world’s leading brands.

C2P is an enterprise SaaS platform providing everything you need in one place to achieve your business objectives by proving compliance in over 195 countries.

C2P is purpose-built to be tailored to your specific needs with comprehensive capabilities that enable enterprise-wide management of regulations, standards, requirements and evidence.

Add-on packages help accelerate market access through use-case-specific solutions, global regulatory content, a global team of subject matter experts and professional services.

- Accelerate time-to-market for products

- Reduce non-compliance risks that impact your ability to meet business goals and cause reputational damage

- Enable business continuity by digitizing your compliance process and building corporate memory

- Improve efficiency and enable your team to focus on business critical initiatives rather than manual tasks

- Save time with access to Compliance & Risks’ extensive Knowledge Partner network

Simplify Corporate Sustainability Compliance

Six months of research, done in 60 seconds. Cut through ESG chaos and act with clarity. Try C&R Sustainability Free.