Ultimate Guide to GHS Labeling and Packaging Requirements: Ensuring Global Compliance in 2025

THIS BLOG WAS WRITTEN BY THE COMPLIANCE & RISKS MARKETING TEAM TO INFORM AND ENGAGE. HOWEVER, COMPLEX REGULATORY QUESTIONS REQUIRE SPECIALIST KNOWLEDGE. TO GET ACCURATE, EXPERT ANSWERS, PLEASE CLICK “ASK AN EXPERT.”

Understanding GHS labeling requirements isn’t just about regulatory compliance – it’s about protecting your workforce, avoiding costly violations, and maintaining operational efficiency across global markets. In 2023 alone, there were 3,213 OSHA HazCom-related violations (compared to 2,682 in 2022), representing a 19% increase and over $50 million in potential penalties. These stark numbers underscore why mastering GHS labeling and packaging requirements has become a critical business imperative.

This comprehensive guide breaks down the complex world of Globally Harmonized System (GHS) labeling into actionable insights, helping you navigate pictograms, signal words, precautionary statements, and hazard statements with confidence. Whether you’re managing chemical inventory, preparing for international shipments, or ensuring workplace safety compliance, this resource will equip you with the knowledge to create effective, compliant labeling systems.

Table of Contents

- Understanding GHS: Foundation for Global Chemical Safety

- The Six Key Elements of GHS Labels

- GHS Pictograms: Visual Communication System

- Signal Words: Immediate Hazard Identification

- Hazard Statements: Specific Risk Communication

- Precautionary Statements: Safety Action Guidelines

- Container Size Standards and Label Formatting

- Multilingual Labeling Requirements

- Electronic vs Physical Labeling Considerations

- Industry-Specific Compliance Considerations

- Common Compliance Violations and How to Avoid Them

- Future of GHS Labeling: Digital Transformation

- Creating a Compliance Management System

- Frequently Asked Questions

Understanding GHS: Foundation for Global Chemical Safety

The Globally Harmonized System of Classification and Labelling of Chemicals represents one of the most significant standardization efforts in industrial safety history. Developed by the United Nations and implemented across more than 70 countries, GHS creates a unified approach to chemical hazard communication that transcends national boundaries.

The system emerged from a critical need to harmonize the diverse chemical classification and labeling systems used worldwide. Before GHS, a chemical classified as hazardous in one country might not receive the same classification in another, creating confusion and safety risks for workers handling these materials across borders.

Core Objectives of GHS Implementation

GHS serves three primary objectives that directly impact business operations. First, it enhances the protection of human health and the environment by providing consistent, internationally understood hazard information. Second, it facilitates international trade by eliminating the need for multiple labeling systems when shipping chemicals globally. Third, it reduces the burden on companies operating in multiple jurisdictions by standardizing classification criteria and label elements.

The implementation timeline varies by region, with most developed countries having fully adopted GHS by 2015. However, ongoing updates to the system – with UNECE publishing the revised GHS Rev.11 on 12 September 2025 – mean that compliance requirements continue to evolve. This dynamic nature of GHS regulations makes staying current with requirements essential for maintaining compliance.

Legal Framework and Enforcement

In the United States, OSHA’s Hazard Communication Standard (29 CFR 1910.1200) incorporates GHS requirements and applies to all workplaces where employees are exposed to hazardous chemicals. OSHA’s 2024 Hazard Communication final rule (aligned principally to GHS Rev.7) took effect July 19, 2024, with compliance dates: substances by January 19, 2026; mixtures by July 19, 2027. Employer program updates must be completed by July 20, 2026 (substances) and January 19, 2028 (mixtures).

Effective January 2025, OSHA’s maximum civil penalties are: Serious/Other-than-Serious $16,550; Willful/Repeat $165,514; Failure to Abate $16,550 per day.

The European Union implements GHS through the Classification, Labelling and Packaging (CLP) Regulation, which aligns closely with the UN GHS framework while addressing specific regional requirements. Similar regulatory frameworks exist across Asia-Pacific, with countries like Japan, South Korea, and Australia having established comprehensive GHS-based regulations.

Understanding this regulatory landscape is crucial because non-compliance can result in more than just financial penalties. Companies may face product recalls, shipping delays, regulatory investigations, and reputational damage that can far exceed the direct costs of violations.

The Six Key Elements of GHS Labels

Every GHS-compliant label must include six mandatory elements, each serving a specific purpose in hazard communication. These elements work together to provide comprehensive information about chemical hazards, proper handling procedures, and emergency response measures.

Product Identifier

The product identifier serves as the primary means of identifying the hazardous chemical on both the label and the safety data sheet (SDS). This identifier must be identical on both documents to ensure clear correlation between the label and detailed hazard information.

For single-component chemicals, the product identifier typically consists of the chemical name or common name. For mixtures, the identifier includes the trade name or common name, along with the names of hazardous ingredients that contribute to the mixture’s hazard classification. The key requirement is consistency – whatever identifier appears on the SDS must exactly match what appears on the label.

Supplier Information

Complete supplier identification ensures that users can contact responsible parties for additional information about the chemical or in case of emergencies. This element must include the name, address, and telephone number of the chemical manufacturer, importer, or other responsible party.

The telephone number should connect to a person knowledgeable about the hazardous chemical and emergency response procedures. Many companies maintain 24-hour emergency response numbers or contract with specialized emergency response services to meet this requirement.

Signal Word

GHS uses two signal words to immediately convey the relative level of severity of hazards: “Danger” for more severe hazard categories and “Warning” for less severe categories. Only one signal word appears on each label, determined by the most severe hazard classification of the chemical.

The signal word serves as an immediate visual cue that helps workers quickly assess the general level of caution required when handling the chemical. This immediate recognition capability is particularly valuable in emergency situations where quick decision-making is critical.

Hazard Statement(s)

Hazard statements provide specific information about the nature of the chemical hazards. Each hazard statement corresponds to a hazard class and category, using standardized phrases designated by unique H-codes. For example, H301 indicates “Toxic if swallowed,” while H315 means “Causes skin irritation.”

Multiple hazard statements may appear on a single label when a chemical presents multiple types of hazards. The standardization of these statements across all GHS-implementing countries ensures consistent hazard communication regardless of geographic location.

Precautionary Statement(s)

While hazard statements describe the nature of hazards, precautionary statements provide guidance on measures to minimize adverse effects. These statements are categorized into prevention, response, storage, and disposal measures, each identified by unique P-codes.

The number of precautionary statements on a label should be limited to the most important measures for the specific hazards present. GHS guidance suggests including no more than six precautionary statements to avoid information overload while ensuring essential safety measures are communicated.

Pictogram(s)

GHS pictograms provide immediate visual recognition of hazard types through standardized symbols displayed within red diamond-shaped borders. Nine pictograms cover different hazard categories, from physical hazards like explosives and flammables to health hazards including carcinogens and respiratory sensitizers.

The visual nature of pictograms makes them particularly valuable in multilingual workplaces or situations where language barriers might impede understanding of text-based hazard information. Their standardized design ensures consistent interpretation across different countries and cultures.

GHS Pictograms: Visual Communication System

GHS pictograms represent the most recognizable aspect of the labeling system, providing immediate visual communication of chemical hazards through internationally standardized symbols. These black symbols on white backgrounds, enclosed in red diamond-shaped borders, transcend language barriers and provide instant hazard recognition.

Physical Hazard Pictograms

The exploding bomb pictogram indicates explosives, self-reactive substances, and organic peroxides that present explosion hazards. Materials displaying this symbol require specialized handling, storage, and transportation procedures to prevent accidental detonation.

The flame pictogram covers flammable gases, aerosols, liquids, and solids, as well as self-heating substances and substances that emit flammable gases when in contact with water. This pictogram is among the most commonly encountered in industrial settings, as many solvents, fuels, and industrial chemicals fall into these categories.

The flame over circle pictogram represents oxidizing gases, liquids, and solids that can cause or intensify fires by providing oxygen or other oxidizing agents. These substances present particular risks when stored or used near flammable materials.

The gas cylinder pictogram indicates gases under pressure, including compressed, liquefied, refrigerated liquefied, and dissolved gases. The primary concerns include explosion risks from pressurized containers and asphyxiation or frostbite hazards from gas releases.

The corrosion pictogram represents substances that are corrosive to metals and may cause severe skin burns and eye damage. These materials require specialized storage containers and personal protective equipment to prevent equipment damage and human injury.

Health Hazard Pictograms

The skull and crossbones pictogram indicates acute toxicity, representing substances that can cause death or serious injury through single or short-term exposure via ingestion, skin contact, or inhalation. This pictogram demands immediate attention and strict handling procedures.

The health hazard pictogram covers a broad range of serious health effects including carcinogenicity, mutagenicity, reproductive toxicity, respiratory sensitization, aspiration toxicity, and specific target organ toxicity. Materials with this pictogram require careful exposure control and often necessitate health surveillance programs for exposed workers.

The exclamation mark pictogram represents less severe health and physical hazards, including acute toxicity (oral, dermal, inhalation), skin and eye irritation, skin sensitization, specific target organ toxicity following single exposure, and narcotic effects. While these hazards are considered less severe than those warranting other pictograms, they still require appropriate precautionary measures.

Environmental Hazard Pictograms

The environment pictogram indicates substances that are hazardous to the aquatic environment. While this pictogram is part of GHS globally, it is not mandatory under OSHA’s Hazard Communication Standard, as environmental hazards are not enforced elements in HCS. It appears on labels for products regulated under other frameworks or intended for international markets where environmental hazard labeling is required.

Pictogram Selection and Prioritization

When a chemical presents multiple hazards that could warrant different pictograms, specific precedence rules determine which pictograms appear on the label. For example, the skull and crossbones pictogram takes precedence over the exclamation mark pictogram for acute toxicity hazards.

These precedence rules prevent label overcrowding while ensuring that the most severe hazards receive primary visual emphasis. Understanding these rules helps in creating compliant labels and interpreting the relative severity of hazards when multiple pictograms appear together.

Signal Words: Immediate Hazard Identification

Signal words serve as the first line of hazard communication, providing immediate indication of hazard severity through two simple terms: “Danger” and “Warning.” This binary system creates instant recognition of whether a chemical presents high or moderate hazard levels, enabling quick risk assessment in workplace environments.

“Danger” Signal Word Applications

The signal word “Danger” appears on labels for chemicals classified in the more severe hazard categories. This includes Category 1 and 2 acute toxicity, Category 1 skin corrosion, Category 1 serious eye damage, Category 1 respiratory sensitization, and Category 1A and 1B carcinogens, mutagens, and reproductive toxins.

When “Danger” appears on a label, it signals the need for the highest level of precautionary measures. Workers encountering chemicals with this signal word should expect comprehensive training requirements, stringent exposure controls, specialized personal protective equipment, and detailed emergency response procedures.

The psychological impact of the word “Danger” should not be underestimated. Research in hazard communication demonstrates that this signal word creates heightened awareness and more cautious behavior compared to less severe warning indicators. This immediate behavioral response can be crucial in preventing accidents and exposures.

“Warning” Signal Word Applications

The signal word “Warning” indicates hazards in less severe categories, including Category 3 and 4 acute toxicity, Category 2 skin irritation, Category 2A eye irritation, Category 1 skin sensitization, and various specific target organ toxicity categories.

While “Warning” indicates lower severity than “Danger,” it still demands appropriate precautionary measures. The key difference lies in the typical level of controls required—warning-level chemicals may require standard personal protective equipment and workplace controls rather than the specialized engineering controls often necessary for danger-level materials.

Signal Word Precedence Rules

When a chemical presents multiple hazards that could warrant different signal words, “Danger” always takes precedence over “Warning.” This precedence system ensures that labels communicate the highest level of hazard present, preventing workers from underestimating risks based on less severe hazard categories.

This precedence rule simplifies label creation and interpretation while maintaining focus on the most critical hazards. It also prevents confusion that could arise from contradictory signal words appearing on the same label.

Integration with Other Label Elements

Signal words work in conjunction with pictograms and hazard statements to create a coherent hazard communication system. The signal word provides immediate severity indication, pictograms offer visual hazard identification, and hazard statements deliver specific hazard information.

Effective hazard communication training emphasizes how these elements work together. Workers learn to first notice the signal word for severity assessment, then examine pictograms for hazard types, and finally read hazard statements for specific hazard information. This systematic approach to label reading improves comprehension and safety outcomes.

Hazard Statements: Specific Risk Communication

Hazard statements form the core of GHS’s standardized hazard communication system, providing specific, consistent language to describe chemical hazards. Each statement corresponds to a unique H-code, creating a global vocabulary for hazard communication that transcends language barriers and regulatory differences.

Physical Hazard Statements (H2XX Series)

Physical hazard statements cover explosive, flammable, oxidizing, and other physical properties that present immediate risks. H200-series codes address explosive hazards, with H200 indicating “Unstable explosive” and progressing through various divisions of explosive materials. These statements require immediate attention due to the catastrophic potential of explosive incidents.

Flammability hazards occupy H220-H230 codes, covering everything from extremely flammable gases (H220) to substances that emit flammable gases in contact with water (H260). Understanding these distinctions is crucial for implementing appropriate fire prevention and suppression measures.

Oxidizing hazards (H270-H272) present unique risks because these materials can intensify fires and cause combustible materials to ignite more readily. Storage and handling procedures for oxidizing materials must account for their ability to create oxygen-rich environments that enhance combustion.

Health Hazard Statements (H3XX Series)

Health hazard statements encompass acute and chronic health effects, ranging from immediate toxicity to long-term health impacts like cancer and reproductive effects. Acute toxicity statements (H300-H331) specify exposure routes – oral, dermal, or inhalation – and severity levels from fatal to harmful.

Chronic health effect statements address some of the most serious workplace health concerns. H340 (“May cause genetic defects”) and H350 (“May cause cancer”) represent hazards that may not manifest for years or decades after exposure but can have devastating health consequences.

Respiratory and skin sensitization statements (H317, H334) identify chemicals that can trigger allergic reactions. These hazards are particularly significant because sensitization can occur at very low exposure levels and, once established, may result in severe reactions to subsequent exposures.

Environmental Hazard Statements (H4XX Series)

Environmental hazard statements address impacts to aquatic environments, with codes ranging from H400 (“Very toxic to aquatic life”) to H413 (“May cause long lasting harmful effects to aquatic life”). While not required under OSHA’s standard, these statements appear on internationally shipped products and help companies demonstrate environmental responsibility.

Statement Selection and Combination Rules

GHS provides specific guidance on combining and selecting appropriate hazard statements when chemicals present multiple hazards. Some statements cannot appear together due to logical conflicts, while others may be combined when a chemical presents multiple distinct hazards.

The goal is to communicate essential hazard information without creating overly complex labels that overwhelm users. This balance requires careful consideration of which hazards present the greatest risks and how to communicate them most effectively.

Customization and Additional Information

While GHS standardizes core hazard statement language, it allows for additional information that clarifies or expands on standard statements. This flexibility enables companies to provide more specific guidance while maintaining the core standardized message.

However, any additional information must not contradict or undermine the standard hazard statement. The goal is enhancement, not replacement, of the standardized hazard communication system.

Precautionary Statements: Safety Action Guidelines

Precautionary statements translate hazard identification into actionable safety guidance, providing specific measures to prevent adverse effects or minimize consequences if exposure occurs. These P-coded statements are organized into four categories – prevention, response, storage, and disposal – creating a comprehensive framework for safe chemical management throughout the product lifecycle.

Prevention Statements (P1XX and P2XX Series)

Prevention statements provide guidance on measures to avoid exposure or minimize risks during normal handling and use. These statements address personal protective equipment, engineering controls, and work practices designed to prevent incidents before they occur.

P-codes in the 100 series cover general prevention measures, while the 200 series addresses specific prevention strategies. P101 (“If medical advice is needed, have product container or label at hand”) appears on virtually all labels, ensuring that critical product information is available during medical emergencies.

Personal protective equipment recommendations appear throughout prevention statements, specifying respiratory protection (P260), eye protection (P264), and protective clothing requirements (P280). These statements help employers and workers select appropriate protective equipment based on specific hazard characteristics.

Work practice prevention statements address handling procedures, area restrictions, and training requirements. P202 (“Do not handle until all safety precautions have been read and understood”) emphasizes the importance of comprehensive safety training before chemical handling begins.

Response Statements (P3XX Series)

Response statements provide guidance for situations where exposure has occurred or is suspected, covering immediate response actions, decontamination procedures, and medical attention requirements. These statements are crucial for emergency preparedness and response planning.

Immediate response statements like P301+P310 (“IF SWALLOWED: Immediately call a POISON CENTER/doctor”) provide clear, step-by-step guidance for exposure situations. The standardized language ensures consistent emergency response regardless of the responder’s familiarity with the specific chemical.

Decontamination response statements address procedures for removing chemicals from skin (P302+P352), eyes (P305+P351+P338), and clothing (P303+P361+P353). These detailed procedures can prevent minor exposures from developing into serious injuries.

Fire response statements provide specific guidance for chemical fires, including appropriate extinguishing agents and special precautions. These statements are particularly important for flammable chemicals where water-based suppression might be ineffective or dangerous.

Storage Statements (P4XX Series)

Storage statements address proper warehousing, inventory management, and containment requirements to maintain chemical integrity and prevent hazardous situations during storage periods. These requirements often extend beyond simple temperature and humidity controls to address compatibility and segregation issues.

Temperature-specific storage requirements appear in statements like P403+P235 (“Store in a well-ventilated place. Keep cool”) for chemicals sensitive to heat or prone to thermal decomposition. These statements help prevent storage-related incidents that could affect entire facilities.

Segregation requirements address incompatible chemical storage, preventing reactions between different chemicals that could create hazardous conditions. P420 (“Store separately”) indicates chemicals that must be isolated from other materials to prevent dangerous interactions.

Container and facility requirements specify storage infrastructure needs, including ventilation, containment, and access controls. These requirements often drive facility design decisions and storage system investments.

Disposal Statements (P5XX Series)

Disposal statements address end-of-life management for chemicals and contaminated materials, ensuring that hazardous substances are managed appropriately throughout their complete lifecycle. These statements are increasingly important as environmental regulations become more stringent and waste disposal costs continue rising.

P501 (“Dispose of contents/container in accordance with local/regional/national/international regulations”) appears on most labels, emphasizing the importance of regulatory compliance in waste management. This statement recognizes that disposal requirements vary significantly by jurisdiction and chemical type.

Specialized disposal statements address specific disposal challenges, such as contaminated packaging, reactive materials, and chemicals that require incineration or other specific treatment methods. These requirements often necessitate working with specialized waste management contractors.

Statement Selection and Limitation Guidelines

GHS recommends limiting precautionary statements to the most important measures for the specific hazards present, generally suggesting no more than six statements to avoid information overload. This limitation requires careful consideration of which measures provide the greatest safety benefit.

Statement selection should prioritize prevention over response measures when both could apply, emphasizing proactive safety management. However, when exposure or incidents could have severe consequences, appropriate response statements become essential despite space limitations.

Container Size Standards and Label Formatting

Container size directly impacts label design, information placement, and readability requirements under GHS regulations. The physical constraints of different container sizes create unique challenges for presenting mandatory label information clearly while maintaining compliance with size, placement, and formatting standards.

Small Container Labeling Requirements

Containers with limited surface area present particular challenges for GHS labeling compliance. When containers are too small to accommodate all required label elements in readable formats, GHS allows for alternative approaches while maintaining essential hazard communication.

For containers with volumes less than 100 milliliters, abbreviated labeling approaches may be acceptable provided that complete GHS information is available through other means, such as safety data sheets or secondary labeling systems. However, product identifier, pictograms, and signal words typically remain mandatory even on small containers.

GHS regulations focus on legibility rather than specifying minimum font point sizes. Requirements emphasize that text should be large enough to be easily read under normal workplace conditions. The EU CLP regulation sets minimum label and pictogram dimensions and provides small-packaging provisions (such as exemptions for containers ≤125 mL) rather than universal point-size rules.

When space constraints prevent full precautionary statement inclusion, priority should be given to prevention statements over response, storage, and disposal statements. This prioritization ensures that the most critical safety information remains visible even when space is severely limited.

Large Container Considerations

Large containers – those exceeding 500 liters – present different challenges related to label visibility, durability, and information organization. These containers often require multiple label placements to ensure hazard information remains visible regardless of storage orientation or access points.

Label size requirements for large containers focus on maintaining proportional visibility rather than minimum dimensions. A label that appears adequately sized on a small container may become practically invisible on a large storage tank or shipping container.

Durability requirements become critical for large containers that may remain in service for extended periods or face harsh environmental conditions. Labels must maintain legibility and adhesion throughout the container’s service life while resisting chemical exposure, weather, and physical handling.

Multiple hazard labeling on large containers may require strategic placement to ensure all hazards are communicated without creating visual confusion. This often involves grouping related hazards or using hierarchical presentation approaches.

Label Placement and Visibility Standards

GHS requires that labels be prominently displayed on containers in locations where they will be easily seen and read under normal conditions of storage and use. This requirement addresses both initial placement and ongoing visibility throughout the container’s lifecycle.

Primary label placement should consider the container’s typical orientation during storage, handling, and use. Labels placed on container bottoms or areas typically obscured by handling equipment fail to meet visibility requirements regardless of their technical compliance with other standards.

Backup labeling systems become important for containers subject to harsh conditions or extended service lives. These might include etched or embossed identification, secondary tags, or duplicate labels in protected locations.

Contrast and readability requirements ensure that label information remains distinguishable under various lighting conditions and viewing angles. High contrast between text and background colors improves readability, particularly in industrial environments with challenging lighting conditions.

International Shipping Considerations

Containers destined for international shipment must accommodate multiple labeling systems, potentially including GHS labels, transportation placards, and destination-country specific requirements. This layered labeling approach requires careful planning to avoid conflicts or information overload.

Transportation regulations often take precedence over GHS labeling during shipment, but GHS labels must remain accessible for workplace hazard communication once containers reach their destinations. When a DOT label for the same hazard is present on a shipped container, the HCS pictogram need not appear to avoid duplicative symbols. This dual requirement may necessitate protective covering or supplemental labeling approaches.

Custom clearance and border inspection procedures may require specific label placement or presentation formats. Understanding destination country requirements helps prevent shipment delays or rejection due to labeling non-compliance.

Language requirements for international shipments often exceed simple GHS compliance, requiring additional text or symbols to meet local regulatory requirements. These additional requirements must be integrated without undermining the clarity of core GHS information.

Multilingual Labeling Requirements

The global nature of modern supply chains creates complex multilingual labeling challenges that extend far beyond simple translation requirements. Effective multilingual GHS labeling must address cultural communication preferences, regulatory variations, and practical implementation constraints while maintaining consistent hazard communication across diverse linguistic environments.

Regulatory Framework for Language Requirements

Different jurisdictions impose varying multilingual requirements based on their specific regulatory frameworks and language policies. In Canada, both English and French labels are mandatory under federal regulations, while the European Union requires labels in the official language(s) of member states where products are marketed.

The United States generally requires English-language labels under OSHA standards, but practical considerations often drive multilingual labeling in workplaces with significant non-English speaking populations. Employers have a responsibility to ensure that hazard communication is understood by all exposed workers, regardless of their primary language.

Some countries specify not only language requirements but also formatting standards for multilingual labels, including font sizes, color requirements, and information hierarchy. These detailed specifications can significantly impact label design and production processes.

Translation Accuracy and Standardization

GHS hazard statements and precautionary statements have been officially translated into many languages through UN processes, ensuring technical accuracy and consistency across jurisdictions. However, product-specific information like product identifiers and supplier information requires careful translation to maintain meaning and legal accuracy.

Technical translation challenges arise when chemical names, hazard concepts, or safety procedures don’t have direct equivalents in target languages. These situations require expert linguistic knowledge combined with technical chemical safety expertise to ensure accurate communication.

Cultural adaptation goes beyond literal translation to address communication styles and safety culture preferences that vary across different regions. What constitutes clear, authoritative safety communication in one culture may be perceived differently in another cultural context.

Quality control for multilingual labels requires verification by native speakers with technical safety backgrounds, not just general translation services. The life-safety implications of hazard communication errors make specialized expertise essential for multilingual labeling programs.

Design and Layout Considerations

Multilingual labels require significantly more space than monolingual versions, creating design challenges particularly for smaller containers. Text expansion ratios vary by language pair, with some languages requiring 30-50% more space than English for equivalent information.

Information hierarchy becomes more complex in multilingual labels, requiring decisions about language presentation order, formatting consistency, and visual organization. Some regulatory frameworks specify requirements for language presentation order, while others leave these decisions to manufacturers.

Font selection and sizing must accommodate character sets and readability requirements for all included languages, which may involve different typography requirements for Latin, Cyrillic, Arabic, or Asian character systems. These technical requirements can significantly impact label production processes.

Color coding and visual symbols become more important in multilingual environments as ways to provide rapid hazard recognition that transcends language barriers. However, cultural color associations vary significantly, requiring careful consideration of visual communication approaches.

Practical Implementation Strategies

Digital label management systems can streamline multilingual labeling by maintaining approved translations, managing version control, and ensuring consistency across production locations. These systems become essential for companies operating in multiple countries with different language requirements.

Regional production strategies may involve creating language-specific label variants close to points of use rather than attempting to create universal multilingual labels for all markets. This approach can improve readability while reducing production complexity.

Training programs for multilingual labeling must address not only technical requirements but also cultural communication preferences and local regulatory expectations. Training effectiveness often requires language-specific materials and instruction methods.

Supply chain coordination becomes more complex with multilingual requirements, particularly when different production locations serve markets with different language requirements. Clear communication protocols help ensure consistency and compliance across distributed operations.

Electronic vs Physical Labeling Considerations

The evolution of digital technologies is reshaping traditional approaches to hazard communication, introducing electronic labeling options that promise enhanced information accessibility, real-time updates, and improved cost efficiency. However, the transition from physical to electronic labeling involves complex regulatory, technical, and practical considerations that require careful evaluation.

Regulatory Framework for Electronic Labels

Current GHS regulations were developed with physical labels as the primary paradigm, and most jurisdictions have not yet fully adapted their regulatory frameworks to accommodate electronic alternatives. OSHA’s Hazard Communication Standard requires that hazard information be “readily accessible” to workers, which has traditionally meant physical labels affixed to containers.

However, regulatory interpretations are evolving to recognize electronic alternatives, particularly in situations where physical labeling is impractical or where electronic systems provide superior hazard communication. These situations often involve secondary containers, temporary storage, or specialized industrial processes where traditional labeling approaches face significant limitations.

Pilot programs and regulatory guidance documents in various jurisdictions are beginning to establish frameworks for electronic labeling acceptance, typically requiring backup systems, worker training, and demonstration of improved or equivalent hazard communication effectiveness compared to traditional approaches.

The legal liability implications of electronic labeling systems require careful consideration, particularly regarding system reliability, information accessibility during emergencies, and demonstration of compliance with existing regulations that may not explicitly address electronic alternatives.

To reference Regulation (EU) 2024/2865, it amended the EU CLP, which provides, among other things, for the introduction of digital labelling. There is also a recent proposal to amend Regulation (EU) 2024/2865, part of an omnibus simplification package.

Technical Implementation Considerations

QR codes and similar machine-readable technologies offer practical bridges between physical containers and electronic information systems. These technologies allow physical placement of scannable codes that provide access to comprehensive, updatable hazard information through mobile devices or dedicated scanning equipment.

Near Field Communication (NFC) and Radio Frequency Identification (RFID) technologies enable more sophisticated electronic labeling approaches, potentially providing automatic hazard information display when workers approach containers or handling areas. However, these technologies require supporting infrastructure and compatible devices.

Cloud-based information systems can provide real-time hazard information updates, ensuring that workers always access current safety data even when chemical formulations or hazard assessments change. This capability addresses a significant limitation of static physical labels that may become outdated.

System reliability and redundancy become critical concerns for electronic labeling, as system failures could leave workers without essential hazard information. Backup systems, offline capabilities, and periodic system testing are essential components of robust electronic labeling implementations.

Worker Acceptance and Training Requirements

Employee acceptance of electronic labeling systems varies significantly based on technological familiarity, workplace culture, and perceived reliability compared to traditional physical labels. Successful implementations typically require comprehensive training programs and change management approaches.

Device availability and accessibility present practical challenges, particularly in industrial environments where personal electronic devices may be prohibited or impractical. Employer-provided devices or dedicated hazard information stations may be necessary to ensure universal access.

Emergency access capabilities become critical considerations, as hazard information must remain accessible during power outages, system failures, or emergency situations when electronic systems may be compromised. Physical backup systems or offline capabilities often remain necessary.

User interface design significantly impacts the effectiveness of electronic labeling systems, requiring intuitive navigation, clear information presentation, and rapid access to essential hazard data. Poor interface design can actually reduce hazard communication effectiveness compared to traditional labeling approaches.

Cost-Benefit Analysis and Implementation Strategy

Initial implementation costs for electronic labeling systems can be substantial, involving software development, hardware deployment, training programs, and system integration efforts. However, ongoing operational costs may be lower than traditional labeling due to reduced printing, inventory, and label replacement requirements.

Scalability considerations become important for organizations with diverse operations, as electronic systems may provide greater benefits in some environments while remaining impractical in others. Hybrid approaches combining physical and electronic elements may provide optimal solutions for many organizations.

Return on investment calculations should consider not only direct labeling costs but also indirect benefits such as improved accuracy, enhanced training capabilities, and better regulatory compliance documentation. These broader benefits often justify electronic system investments even when direct cost savings are limited.

Change management strategies require careful planning to ensure successful transitions from physical to electronic labeling systems, addressing worker concerns, regulatory compliance requirements, and operational continuity needs throughout implementation periods.

Industry-Specific Compliance Considerations

Different industrial sectors face unique GHS labeling challenges based on their operational characteristics, regulatory environments, and risk profiles. Understanding these sector-specific considerations is essential for developing effective compliance strategies that address both general GHS requirements and industry-specific regulatory expectations.

Chemical Manufacturing and Processing

Chemical manufacturing facilities face the most complex GHS labeling challenges due to the diversity of hazardous materials, frequent product changes, and sophisticated processing operations. These environments often involve hundreds or thousands of different chemicals with varying hazard profiles and regulatory requirements.

Process safety management requirements in chemical facilities often necessitate enhanced labeling approaches that integrate with broader safety management systems. Labels must not only communicate hazards but also support process safety analyses, emergency response procedures, and regulatory compliance documentation.

Intermediate products and byproducts in chemical processing create unique labeling challenges, as these materials may not have established commercial identities but still require appropriate hazard communication. Custom labeling approaches are often necessary to address these materials while maintaining consistency with GHS principles.

Research and development activities in chemical facilities involve experimental materials with uncertain or evolving hazard profiles, requiring flexible labeling approaches that can accommodate changing information while maintaining adequate worker protection.

Pharmaceutical and Biotechnology

Pharmaceutical manufacturing involves specialized materials including active pharmaceutical ingredients (APIs), excipients, and intermediate compounds that may present unique hazard profiles not fully addressed by standard GHS categories. These materials often require specialized hazard assessments and customized labeling approaches.

Good Manufacturing Practices (GMP) requirements in pharmaceutical facilities create additional labeling considerations beyond basic GHS compliance, including lot tracking, expiration dating, and quality control information that must be integrated with hazard communication elements.

Biological materials and biotechnology products may present hazards not fully covered by traditional GHS chemical hazard categories, requiring specialized labeling approaches that address biological risks, containment requirements, and specialized handling procedures.

Clinical trial materials and investigational drugs require labeling approaches that balance hazard communication with regulatory requirements for blinding, patient safety, and investigational product management.

Electronics and Technology Manufacturing

Electronics manufacturing involves numerous hazardous chemicals including solvents, acids, and exotic materials used in semiconductor processing and assembly operations. These materials often present unique combinations of hazards requiring careful labeling consideration.

Clean room environments in electronics manufacturing create special labeling challenges due to contamination control requirements, space limitations, and specialized handling procedures that may affect traditional labeling approaches.

Supply chain complexity in electronics manufacturing, with components and materials sourcing from multiple global suppliers, requires robust systems for ensuring consistent GHS labeling and hazard communication across diverse supply networks.

Rapid technology changes in electronics manufacturing may involve new materials with limited hazard data, requiring conservative labeling approaches and ongoing hazard assessment updates as new information becomes available.

Construction and Building Materials

Construction industry applications involve materials that may be used in various configurations and environments, requiring labeling approaches that address diverse exposure scenarios and application methods.

Building product manufacturers must consider end-user applications that may involve cutting, sanding, heating, or other activities that could alter hazard profiles compared to the original manufactured product.

Weather resistance and durability requirements for construction material labels must address outdoor exposure, temperature extremes, and physical handling that could compromise label integrity over extended periods.

Contractor and subcontractor communication requires labeling approaches that ensure hazard information reaches workers who may not be employed by the primary manufacturer or supplier but still face exposure risks.

Transportation and Logistics

Transportation regulations create overlapping requirements with GHS labeling, as materials in commerce must comply with both workplace hazard communication standards and transportation safety regulations. These dual requirements often necessitate complex labeling approaches.

International shipping creates additional complications as materials may transit through multiple regulatory jurisdictions with different labeling requirements, potentially requiring multiple label systems or complex multi-jurisdictional compliance approaches.

Warehouse and distribution center operations involve temporary storage and repackaging activities that must maintain GHS compliance while accommodating logistics efficiency and operational requirements.

Emergency response preparedness in transportation requires labeling approaches that support rapid hazard identification and appropriate response measures for incidents occurring during transport or storage.

Common Compliance Violations and How to Avoid Them

Analysis of OSHA inspection data reveals recurring patterns in GHS labeling violations that represent significant compliance risks for organizations across various industries. Understanding these common failure modes and implementing preventive strategies can help organizations avoid costly violations while improving overall safety performance.

Missing or Incomplete Label Elements

The most frequent GHS violations involve labels missing one or more of the six required elements. Product identifier omissions are particularly common when products undergo repackaging or when secondary containers are filled from bulk materials without proper labeling transfer procedures.

Signal word omissions often occur when hazard classifications change due to updated safety data but labeling systems fail to incorporate these changes. This situation is particularly common with chemical mixtures where component changes or concentration adjustments affect overall hazard classifications.

Pictogram errors represent another frequent violation category, including use of outdated symbols, incorrect pictogram selection for specific hazards, or pictogram omissions when space constraints lead to arbitrary label element removal.

Supplier information violations often involve incomplete contact information, particularly missing or incorrect telephone numbers for emergency contacts. These violations are especially problematic because they can impede emergency response when immediate access to technical expertise is critical.

Prevention strategies for missing elements include comprehensive labeling checklists, systematic quality control procedures, and automated labeling systems that prevent label generation without complete information input.

Inconsistency Between Labels and Safety Data Sheets

Discrepancies between label information and safety data sheet content represent serious violations that can confuse workers and compromise hazard communication effectiveness. These inconsistencies most commonly involve product identifiers that don’t match exactly between documents.

Hazard classification differences between labels and SDSs often result from timing differences in document updates or different interpretation of hazard data by different personnel. Establishing synchronized update procedures helps prevent these discrepancies from occurring.

Precautionary statement inconsistencies can arise when label space constraints lead to abbreviated statements that don’t align with full statements in safety data sheets. While abbreviation may be necessary, the abbreviated version must convey equivalent safety guidance.

Document version control systems help prevent label-SDS inconsistencies by ensuring that related documents are updated simultaneously and that version tracking prevents the use of outdated information in label creation.

Secondary Container Labeling Failures

Secondary container labeling represents a significant compliance challenge because it often involves workplace-level decisions rather than manufacturer-controlled processes. Workers transferring chemicals to smaller containers frequently fail to transfer complete labeling information.

Common secondary container violations include missing hazard statements, omitted pictograms, and absent precautionary statements. These omissions often result from assumptions that abbreviated labeling is acceptable for workplace-generated secondary containers.

Temporary container labeling creates additional challenges when materials are transferred to containers intended for short-term use. Even temporary containers require appropriate hazard communication, though the specific requirements may vary based on duration and use circumstances.

Training programs for secondary container labeling must address both regulatory requirements and practical implementation challenges, providing clear guidance on when full labeling is required versus when abbreviated approaches may be acceptable.

Language and Readability Issues

Language-related violations include use of non-English text in jurisdictions requiring English labels, inadequate translation quality for mandated multilingual labels, and use of technical terminology that workers cannot reasonably understand.

Font size and color contrast violations compromise label readability under normal workplace conditions. These violations often result from cost-cutting measures that reduce label size below practical readability thresholds.

Abbreviation and acronym use can create comprehension problems, particularly when abbreviations are not universally understood or when they create ambiguity about safety requirements. Standard abbreviations may be acceptable, but unique or uncommon abbreviations should be avoided.

Clear writing principles help prevent readability violations by ensuring that label text uses appropriate vocabulary levels, sentence structures, and formatting approaches that support rapid comprehension under various workplace conditions.

Update and Maintenance Failures

Label obsolescence represents a growing compliance risk as chemical formulations change, hazard assessments are updated, and regulatory requirements evolve. Failure to update labels when underlying information changes creates serious compliance and safety risks.

Damage and deterioration of physical labels must be addressed through systematic inspection and replacement programs. Labels that become illegible due to chemical exposure, weather, or physical damage fail to meet regulatory requirements regardless of their initial compliance.

Inventory management for labeling materials helps prevent use of outdated label templates or information that no longer reflects current hazard assessments or regulatory requirements. Version control systems should ensure that only current label versions are available for use.

Systematic update procedures should address trigger events for label revisions, including formulation changes, new hazard data, regulatory updates, and periodic compliance reviews. These procedures help ensure that labels remain current throughout product lifecycles.

Future of GHS Labeling: Digital Transformation

The convergence of digital technologies, artificial intelligence, and evolving regulatory frameworks is reshaping the landscape of chemical hazard communication. Understanding these emerging trends helps organizations prepare for future compliance requirements while capitalizing on opportunities for improved safety performance and operational efficiency.

Artificial Intelligence and Automated Classification

Machine learning algorithms are increasingly being applied to chemical hazard classification, offering the potential for more consistent, accurate, and rapid hazard assessments. These systems can analyze vast databases of chemical structure and toxicity data to predict hazard classifications for new or poorly characterized substances.

Natural language processing technologies are being developed to automatically generate appropriate hazard statements and precautionary statements based on chemical properties and intended uses. These systems could reduce human error in labeling while ensuring consistency across large product portfolios.

Automated compliance checking systems can review label designs against regulatory requirements, identifying potential violations before labels are produced and implemented. These systems become increasingly valuable as regulatory complexity grows and update frequencies increase.

Predictive analytics applications can identify patterns in hazard data that might indicate emerging risks or suggest opportunities for improved chemical management strategies. These insights could drive proactive safety improvements that extend beyond simple regulatory compliance.

Internet of Things (IoT) Integration

Smart container technologies incorporating sensors and communication capabilities can provide real-time monitoring of chemical conditions, automatically updating hazard information based on degradation, contamination, or environmental exposure that might affect chemical properties.

Environmental monitoring integration allows labeling systems to incorporate real-time workplace condition data, potentially adjusting exposure guidance or emergency response procedures based on current temperature, humidity, or ventilation conditions.

Location-aware labeling systems can provide context-specific hazard information based on where chemicals are being used, stored, or transported. This capability could enable more targeted safety guidance that addresses specific environmental and operational conditions.

Automated inventory tracking through IoT systems can ensure that labels remain current with actual chemical inventory, preventing situations where labeling information doesn’t reflect the actual materials present in workplace locations.

Blockchain and Supply Chain Transparency

Blockchain technologies offer potential solutions for maintaining labeling integrity and traceability throughout complex global supply chains. Immutable records of hazard assessments, labeling changes, and safety data could improve accountability and compliance verification.

Supply chain transparency through blockchain systems could enable real-time verification of chemical source information, hazard assessments, and compliance status throughout distribution networks. This transparency could be particularly valuable for complex chemical mixtures with multiple component sources.

Smart contracts on blockchain platforms could automatically trigger labeling updates when predefined conditions are met, such as regulatory changes, new hazard data, or supply chain modifications that affect chemical properties.

Authentication and anti-counterfeiting measures using blockchain technologies could help ensure that chemical products and their associated hazard information are genuine, addressing growing concerns about counterfeit chemicals in global markets.

Regulatory Evolution and Harmonization

Ongoing GHS revision processes continue to refine requirements and address emerging technologies, with recent revisions incorporating guidance for nanomaterials, mixture classification improvements, and updated precautionary statements.

The EU introduced significant changes through Delegated Regulation (EU) 2023/707, which established new CLP hazard classes for endocrine disruption (human and environment), PBT/vPvB, and PMT/vPvM. New substances must be classified under these classes from May 1, 2025; mixtures from May 1, 2026, with transition periods for existing products. These additions reflect growing regulatory focus on substances of very high concern and their long-term environmental impacts.

Regional harmonization efforts are gradually reducing differences between national implementations of GHS, potentially simplifying compliance for multinational operations while improving global supply chain efficiency.

Digital-native regulatory frameworks are beginning to emerge, designed specifically to accommodate electronic labeling, automated compliance systems, and digital supply chain integration rather than retrofitting traditional approaches to digital technologies.

Performance-based regulations that focus on safety outcomes rather than prescriptive labeling requirements could provide greater flexibility for innovative approaches to hazard communication while maintaining or improving safety performance.

Augmented Reality and Enhanced Worker Interaction

Augmented reality applications can overlay additional hazard information, safety guidance, or emergency response instructions onto physical chemical containers, providing enhanced information access without compromising traditional labeling approaches.

Real-time translation capabilities through AR systems could provide immediate multilingual hazard communication in diverse workplace environments, addressing language barriers more effectively than traditional multilingual labeling approaches.

Interactive training systems using AR or virtual reality can provide immersive experiences for learning GHS labeling interpretation, hazard recognition, and emergency response procedures in realistic but safe training environments.

Context-aware safety guidance through AR systems could provide specific safety recommendations based on current workplace conditions, chemical combinations present, or planned activities, enabling more targeted and effective safety communication.

Augmented reality applications can overlay additional hazard information, safety guidance, or emergency response instructions onto physical chemical containers, providing enhanced information access without compromising traditional labeling approaches.

Real-time translation capabilities through AR systems could provide immediate multilingual hazard communication in diverse workplace environments, addressing language barriers more effectively than traditional multilingual labeling approaches.

Interactive training systems using AR or virtual reality can provide immersive experiences for learning GHS labeling interpretation, hazard recognition, and emergency response procedures in realistic but safe training environments.

Context-aware safety guidance through AR systems could provide specific safety recommendations based on current workplace conditions, chemical combinations present, or planned activities, enabling more targeted and effective safety communication.

Creating a Compliance Management System

Developing a comprehensive GHS labeling compliance management system requires integrating regulatory requirements, operational procedures, and quality control measures into a cohesive framework that ensures consistent compliance while supporting operational efficiency and continuous improvement.

Regulatory Monitoring and Update Procedures

Regulatory intelligence systems must track GHS updates across all relevant jurisdictions, including UN revisions to the core GHS framework and national implementation changes that affect labeling requirements. These systems should provide early warning of pending changes to allow adequate preparation time.

Impact assessment procedures should evaluate how regulatory changes affect existing labeling systems, identify required updates to labels and procedures, and estimate implementation costs and timelines. These assessments help prioritize compliance activities and resource allocation.

Change management processes should ensure that regulatory updates are communicated to relevant personnel, incorporated into labeling procedures, and implemented according to required timelines. Documentation systems should track compliance status and provide audit trails for regulatory inspections.

Stakeholder communication procedures should keep relevant departments informed about regulatory changes that affect their operations, including purchasing, manufacturing, logistics, and safety departments that play roles in labeling compliance.

Hazard Assessment and Classification Procedures

Systematic hazard assessment procedures should ensure that all chemicals receive appropriate classification based on available data, regulatory requirements, and scientific evidence. These procedures should address both purchased chemicals and manufactured products.

Data collection systems should gather relevant toxicity, physical property, and environmental hazard data from multiple sources, including supplier information, published literature, and internal testing data. Data quality assessment procedures should evaluate information reliability and completeness.

Classification decision documentation should record the basis for hazard classifications, including data sources, decision criteria, and review processes. This documentation supports regulatory compliance and provides the foundation for label generation.

Review and update procedures should ensure that hazard assessments remain current as new data becomes available, chemical formulations change, or regulatory requirements evolve. Systematic review schedules help prevent outdated assessments from affecting labeling accuracy.

Label Design and Production Control

Design standards should establish consistent approaches to label layout, formatting, and information presentation that ensure compliance while maintaining clarity and professional appearance. These standards should address various container sizes and types.

Template management systems should provide approved label formats for different chemical categories, container types, and regulatory requirements. Version control procedures should prevent use of outdated templates and ensure consistency across production locations.

Quality control procedures should verify label accuracy before production, including verification of hazard information, spelling and grammar checking, and compliance with regulatory requirements. Systematic checking procedures help prevent errors that could result in violations or safety issues.

Production monitoring should ensure that labels are produced according to approved specifications and that quality standards are maintained throughout production runs. Batch tracking systems should enable identification and correction of any quality issues that arise.

Training and Competency Management

Role-based training programs should address specific GHS labeling responsibilities for different positions within the organization, including chemical handlers, labeling personnel, safety professionals, and management personnel with compliance oversight responsibilities.

Competency assessment procedures should verify that personnel understand their labeling responsibilities and can perform required tasks effectively. These assessments should address both initial training and ongoing competency maintenance.

Update training should ensure that personnel receive information about regulatory changes, procedure updates, and lessons learned from compliance issues or safety incidents. Training effectiveness should be evaluated and improved based on assessment results.

Documentation systems should track training completion, competency assessments, and ongoing qualification maintenance for all personnel with GHS labeling responsibilities. These records support compliance demonstrations and identify training needs.

Performance Monitoring and Continuous Improvement

Compliance monitoring procedures should systematically evaluate labeling compliance across all operations, identifying trends, patterns, and improvement opportunities. These procedures should include both scheduled audits and responsive investigations of potential issues.

Key performance indicators should track compliance metrics, training effectiveness, system performance, and safety outcomes related to hazard communication. These metrics help identify areas requiring attention and demonstrate improvement over time.

Corrective action procedures should address identified compliance issues through systematic root cause analysis, corrective measure implementation, and effectiveness verification. Documentation systems should track issues and resolutions to prevent recurrence.

Management review processes should evaluate compliance system performance, resource adequacy, and improvement opportunities at appropriate intervals. These reviews should drive strategic decisions about system enhancements and resource allocation.

Frequently Asked Questions

- Q: What happens if a chemical presents multiple hazards requiring different signal words?

When a chemical presents multiple hazards that could warrant different signal words, only one signal word appears on the label, determined by precedence rules. “Danger” always takes precedence over “Warning,” regardless of the number of warning-level hazards present. This approach prevents consumer confusion while ensuring that the highest severity level receives appropriate emphasis. All relevant hazard statements and pictograms still appear on the label, providing complete hazard information even though only the higher-severity signal word is displayed. - Q: Are there specific requirements for label durability and weather resistance?

While GHS doesn’t specify detailed durability requirements, labels must remain legible and securely attached throughout the container’s intended use period. This means labels exposed to outdoor conditions, chemical exposure, or physical handling must be designed to withstand these conditions without degrading. Factors affecting durability include adhesive selection, substrate materials, ink or printing methods, and protective coatings. Many organizations establish internal durability standards based on their specific operating environments and conduct testing to verify label performance under expected conditions. - Q: How do I handle labeling for chemical mixtures with proprietary formulations?

Chemical mixtures require hazard classification based on the overall mixture properties, not individual component hazards. The product identifier should reflect the mixture’s commercial name, while hazard statements should address the mixture’s actual hazards. For proprietary formulations, you’re required to disclose hazardous ingredients that contribute to the mixture’s classification, but complete formulation disclosure isn’t required unless specifically mandated by other regulations. Trade secret protections generally remain valid provided that essential hazard information is clearly communicated through appropriate GHS elements. - Q: What are the requirements for secondary container labeling in workplaces?

Secondary containers – those filled from bulk chemicals in workplace settings – must include appropriate hazard information, though the specific requirements depend on the container’s intended use and duration. Containers intended for immediate use by the person who filled them during a single work shift may require minimal labeling, while containers intended for longer-term use or use by multiple workers require more comprehensive labeling. At minimum, secondary containers should include the product identifier and primary hazard information. Many organizations develop standardized procedures for secondary container labeling to ensure consistency and compliance. - Q: How do international shipping requirements interact with GHS labeling?

International shipping involves overlapping requirements from GHS workplace regulations and transportation safety regulations. Transportation placards and labels address shipping hazards and may differ from workplace GHS requirements. Packages must comply with both systems, often requiring transportation labels during shipping and workplace GHS labels for end-use applications. Some harmonization exists between systems, but differences remain, particularly for classification criteria and presentation formats. Successful international shipping requires understanding both regulatory frameworks and planning for compliance with both during different phases of the product lifecycle. - Q: Can QR codes or other technology replace traditional physical labels?

Current GHS regulations were developed assuming physical labels, and most jurisdictions haven’t formally approved electronic alternatives as complete replacements for traditional labeling. However, regulatory interpretations are evolving, and some applications of electronic systems are gaining acceptance, particularly as supplements to traditional labeling or in situations where physical labeling is impractical. QR codes linking to complete hazard information are increasingly common as enhancements to traditional labels. Full electronic replacement typically requires demonstration that the electronic system provides equivalent or superior hazard communication compared to traditional approaches, along with appropriate backup systems for situations where electronic access might be limited.

Understanding and implementing comprehensive GHS labeling requirements represents a critical investment in workplace safety, regulatory compliance, and operational excellence. The complexity of these requirements – spanning hazard classification, label design, supply chain coordination, and ongoing compliance management – demands systematic approaches and expert guidance.

Organizations that master GHS compliance don’t just avoid violations; they create competitive advantages through improved safety performance, streamlined global operations, and enhanced supply chain integration. The future of chemical hazard communication will continue evolving with digital technologies, regulatory harmonization, and emerging scientific understanding of chemical risks.

Success in this environment requires more than understanding current requirements—it demands systems and strategies that can adapt to changing regulations while maintaining consistent safety performance. Whether you’re managing a single facility or coordinating global supply chains, the principles and strategies outlined in this guide provide the foundation for building robust, compliant, and effective GHS labeling programs that protect workers while supporting business objectives.

For organizations ready to transform their approach to global compliance management, professional guidance and systematic implementation support can accelerate results while minimizing risks during the transition to comprehensive GHS compliance systems.

Stay Ahead Of Regulatory Changes in GHS

Want to stay ahead of regulatory developments in GHS?

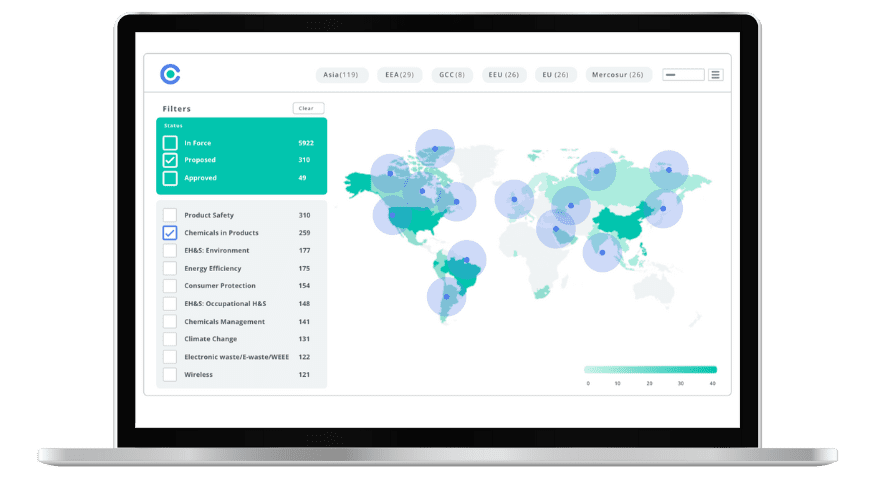

Accelerate your ability to achieve, maintain & expand market access for all products in global markets with C2P – your key to unlocking market access, trusted by more than 300 of the world’s leading brands.

C2P is an enterprise SaaS platform providing everything you need in one place to achieve your business objectives by proving compliance in over 195 countries.

C2P is purpose-built to be tailored to your specific needs with comprehensive capabilities that enable enterprise-wide management of regulations, standards, requirements and evidence.

Add-on packages help accelerate market access through use-case-specific solutions, global regulatory content, a global team of subject matter experts and professional services.

- Accelerate time-to-market for products

- Reduce non-compliance risks that impact your ability to meet business goals and cause reputational damage

- Enable business continuity by digitizing your compliance process and building corporate memory

- Improve efficiency and enable your team to focus on business critical initiatives rather than manual tasks

- Save time with access to Compliance & Risks’ extensive Knowledge Partner network

Simplify Corporate Sustainability Compliance

Six months of research, done in 60 seconds. Cut through ESG chaos and act with clarity. Try C&R Sustainability Free.