Design Strategies for EPR & Circular Economy Compliance: The Complete Implementation Guide

THIS BLOG WAS WRITTEN BY THE COMPLIANCE & RISKS MARKETING TEAM TO INFORM AND ENGAGE. HOWEVER, COMPLEX REGULATORY QUESTIONS REQUIRE SPECIALIST KNOWLEDGE. TO GET ACCURATE, EXPERT ANSWERS, PLEASE CLICK “ASK AN EXPERT.”

The shift from environmental aspiration to regulatory reality has arrived. Extended Producer Responsibility (EPR) laws across global markets are transforming sustainable design from a nice-to-have into a business-critical compliance requirement. Smart companies are discovering that proactive circular design strategies don’t just ensure regulatory compliance – they unlock significant cost savings, reduce eco-modulated fees, and future-proof product lines against increasingly stringent regulations.

This comprehensive guide bridges the gap between circular economy principles and practical implementation, providing product designers, engineers, and compliance managers with actionable frameworks for EPR compliance. You’ll discover how specific design choices directly impact your bottom line, implement material traceability systems ahead of Digital Product Passport requirements, and build products that thrive in the circular economy.

Table of Contents

- The Business Case for Circular Design

- Core Pillars of Design for a Circular Economy

- Design for Disassembly & Modularity

- Design for Longevity & Repair

- Design for Recycling Excellence

- The Implementation Playbook

- Material Substitution Framework

- Building Material Traceability Systems

- EPR Pre-Compliance Audit

- Real-World Success Stories

- Future-Proofing Your Design Strategy

- FAQ

The Business Case for Circular Design

Market Reality: Compliance is Driving Growth

The circular economy represents more than environmental stewardship—it’s a $450 billion market in 2024 projected to reach $1.0 trillion by 2032, growing at 11.5% annually. This explosive growth stems largely from regulatory pressure as governments worldwide implement comprehensive EPR schemes.

EPR effectiveness data reveals the financial scope of this transformation. In the European Union alone, EPR schemes drove a 50% reduction in packaging landfilling over 20 years, while South Korea achieved 70% higher recycling rates between 2003-2017 after implementing comprehensive producer responsibility frameworks.

The True Cost of Non-Compliance

Modern EPR schemes employ eco-modulated fees that directly penalize poor design choices while rewarding circular design principles. Companies using non-recyclable materials, difficult-to-disassemble components, or materials lacking traceability face significantly higher producer fees.

Consider packaging EPR schemes where fees can vary by 200-300% based on recyclability criteria. A product designed with clear material identification, mono-material construction, and disassembly-friendly connections might pay €0.50 per unit in producer fees, while a comparable product using mixed materials and permanent adhesives could face €1.50 per unit – multiplied across millions of units, design choices become major cost drivers.

ROI Calculation Framework

Smart companies calculate circular design ROI across four key metrics:

Direct Cost Reductions:

- Lower EPR fees through eco-modulated pricing

- Reduced material costs through design optimization

- Decreased waste disposal fees

Revenue Enhancement:

- Premium pricing for certified sustainable products

- Access to sustainability-focused procurement requirements

- Extended product lifecycles through modular design

Risk Mitigation:

- Regulatory future-proofing against tightening standards

- Supply chain resilience through diversified material sourcing

- Brand protection against greenwashing accusations

Market Access:

- Qualification for green procurement programs

- Enhanced B2B customer relationships

- Competitive differentiation in sustainability-focused markets

Core Pillars of Design for a Circular Economy

Effective circular design rests on three interconnected foundations that directly address EPR compliance requirements while creating business value.

Design for Disassembly & Modularity

Disassembly-friendly design enables end-of-life material recovery while creating opportunities for component reuse and repair. This approach directly reduces EPR fees by maximizing material circularity potential.

Key Design Principles:

Fastener Strategy: Replace permanent connections (adhesives, welding, rivets) with reversible mechanical fasteners. Use standardized screw types to minimize required tools. Color-code or clearly mark fasteners that must be removed for material separation.

Material Separation Optimization: Design clear break points between different material types. Avoid composite materials that cannot be mechanically separated. Use compatible materials that can be recycled together when separation isn’t practical.

Component Modularity: Create self-contained modules that can be individually repaired, upgraded, or recycled. Design modules around material types – all electronics in one module, all plastics in another, all metals in a third.

Visual Identification Systems: Incorporate clear material identification markings that remain readable throughout the product lifecycle. Use universal recycling symbols and material codes. Consider QR codes linking to detailed disassembly instructions.

Design for Longevity & Repair

Extended product lifespans reduce environmental impact while supporting business model innovations like product-as-a-service offerings. Many EPR schemes now incorporate durability requirements that directly affect producer compliance costs.

Structural Durability Optimization

Design components to exceed expected service life. Use fatigue analysis to identify failure points and over-engineer critical stress areas. Incorporate wear-resistant materials in high-friction applications. Design for graceful degradation where partial functionality continues even after component wear.

Modular Repair Architecture

Create easily accessible service points for common maintenance tasks. Design standardized interfaces that allow component swapping without specialized tools or training. Provide clear service documentation with step-by-step repair procedures.

Component Standardization

Use industry-standard components where possible to ensure long-term parts availability. Design custom components with backward compatibility for multiple product generations. Create component families that share common interfaces across product lines.

Design for Recycling Excellence

Recycling-optimized design maximizes material recovery value while minimizing processing costs – key factors in eco-modulated EPR fee calculations.

Material Selection Strategy

Prioritize mono-materials over composite materials wherever performance requirements allow. Choose materials with established recycling infrastructure in target markets. Understand local recycling capabilities and design accordingly – what works in Germany may not work in developing markets.

Contamination Prevention

Eliminate materials that contaminate recycling streams. Avoid using adhesives that cannot be removed during recycling processes. Design ink and coating systems that don’t interfere with material identification or processing.

Processing Efficiency

Design for standard recycling equipment capabilities. Consider shredder-friendly geometries that break into appropriate particle sizes. Avoid designs that create problematic waste streams like small particles that fall through sorting equipment.

Quality Recovery Optimization

Maintain material purity through design choices. Use compatible additives that don’t degrade recycling quality. Design joints and connections that separate cleanly during recycling processes.

The Implementation Playbook

Moving from principles to practice requires systematic frameworks for material selection, traceability implementation, and compliance verification.

Material Substitution Framework

Effective material substitution balances multiple criteria: regulatory compliance, cost impact, performance requirements, and recycling infrastructure availability.

Step 1: Comprehensive Material Audit

Document every material in your product portfolio with detailed specifications:

- Base material composition and additives

- Current supplier information and certification status

- Regulatory compliance status across target markets

- End-of-life processing options in each market

- Cost per unit and annual volume

Step 2: Substitution Criteria Matrix

Evaluate potential substitutes across four key dimensions:

Compliance Score (40% weighting):

- EPR scheme compatibility

- Recyclability infrastructure availability

- Material identification clarity

- Contamination potential

Cost Impact (30% weighting):

- Direct material cost differential

- Processing cost changes

- Tooling modification requirements

- Supply chain disruption costs

Performance Match (20% weighting):

- Mechanical property alignment

- Aesthetic characteristics

- Durability comparison

- Processing compatibility

Risk Assessment (10% weighting):

- Supplier reliability

- Long-term availability

- Price volatility history

- Technology maturity

Step 3: Implementation Roadmap

Prioritize substitutions based on:

- High compliance risk materials (immediate action)

- High-volume materials (maximum impact)

- Materials with readily available alternatives (quick wins)

- Materials approaching end-of-supply (forcing functions)

Create phased rollout schedules that coordinate with product refresh cycles, supplier contract renewals, and regulatory deadlines.

Building Material Traceability Systems

Digital Product Passports and enhanced EPR reporting requirements demand comprehensive material traceability. Smart companies build these capabilities before regulatory mandates, gaining competitive advantages through supply chain transparency.

Data Architecture Requirements

Implement systems that capture:

- Complete bill of materials with supplier information

- Material origin and processing history

- Recycled content percentages and certifications

- Chemical composition and substance declarations

- End-of-life instructions and recycling codes

Integration with Existing Systems

Connect traceability systems with:

- Enterprise resource planning (ERP) platforms

- Product lifecycle management (PLM) software

- Compliance management solutions

- Supplier data management systems

- Quality assurance databases

Digital Product Passport Preparation

The EU’s Ecodesign for Sustainable Products Regulation (ESPR) requires comprehensive product information through Digital Product Passports. Prepare by:

- Establishing unique product identifiers

- Creating standardized data formats

- Building secure data sharing protocols

- Implementing version control systems

- Ensuring data accuracy and completeness

EPR Pre-Compliance Audit

Regular compliance audits identify gaps before they become costly violations. Use this framework to assess your readiness for current and upcoming EPR requirements.

Documentation Review

Verify completeness of:

- Material declarations and safety data sheets

- Supplier certifications and chain of custody

- Design for recycling documentation

- Disassembly instructions and service manuals

- Compliance evidence for all markets

Design Assessment

Evaluate products against:

- Current EPR recyclability criteria

- Emerging circular economy requirements

- Industry best practices for sustainable design

- Competitor benchmarks and market leaders

- Future regulatory trends and draft legislation

Fee Optimization Analysis

Calculate potential savings through:

- Material substitution opportunities

- Design for disassembly improvements

- Modular architecture benefits

- Recycled content integration

- Eco-modulation tier improvements

Real-World Success Stories

Electronics Manufacturer: Modular Design Success

A global electronics manufacturer redesigned their product line with modular architecture, achieving:

- 40% reduction in EPR fees through improved recyclability scores

- 25% decrease in warranty claims through easier repair

- 15% increase in customer satisfaction from upgrade options

- ROI achieved within 18 months of implementation

Key success factors included early supplier engagement, phased rollout aligned with product cycles, and comprehensive technician training programs.

Packaging Innovation: Mono-Material Transition

A consumer goods company transitioned to mono-material packaging, resulting in:

- 60% lower EPR fees in markets with eco-modulated pricing

- 30% reduction in material costs through optimization

- 20% improvement in recycling rates at end-of-life

- Enhanced brand reputation for sustainability leadership

The transition required close collaboration with packaging suppliers, consumer testing for acceptance, and investment in new production equipment.

Textile Industry: Circular Design Integration

A fashion brand implemented comprehensive circular design principles:

- Achieved compliance with emerging textile EPR requirements

- Reduced material waste by 35% through pattern optimization

- Created new revenue streams through take-back programs

- Positioned for compliance with upcoming regulations

Success required supply chain transparency, material innovation partnerships, and consumer education programs.

Future-Proofing Your Design Strategy

Emerging Regulatory Trends

Stay ahead of regulatory evolution by monitoring:

- EU Circular Economy Act development

- Expansion of battery passport requirements

- New ecodesign requirements for additional product categories

- Harmonization efforts across jurisdictions

- Industry-specific sustainability standards

Technology Integration

Leverage emerging technologies for circular design:

- AI-powered material selection tools

- Blockchain for supply chain traceability

- IoT sensors for product lifecycle monitoring

- Digital twins for design optimization

- Automated compliance assessment platforms

Continuous Improvement Framework

Establish processes for ongoing optimization:

- Regular design reviews against latest requirements

- Supplier capability assessments and development

- Cross-functional collaboration on sustainability

- Performance metrics and reporting systems

- Innovation partnerships with recyclers and material suppliers

Frequently Asked Questions

- Q: How do circular design choices affect EPR fees?

Eco-modulated EPR schemes directly link design choices to fee levels. Products with superior recyclability, clear material identification, and easy disassembly can qualify for reduced fees – sometimes 50-70% lower than poorly designed alternatives. The C2P platform helps track these requirements across multiple jurisdictions. - Q: What’s the timeline for Digital Product Passport implementation?

The EU’s battery regulation requires passports for industrial and EV batteries by 2027. The ESPR framework will extend requirements to other products through delegated acts. Certain companies should begin preparing data systems now to ensure readiness. - Q: How can small companies manage circular design complexity?

Start with high-impact, low-complexity improvements like material standardization and clear labeling. Use industry associations and PRO resources for guidance. Consider phased implementation aligned with product development cycles. The Product Compliance Solution from Compliance & Risks provides scalable tools for companies of all sizes. - Q: What are the risks of not adopting circular design?

Beyond higher EPR fees, risks include market access restrictions, customer defection to sustainable alternatives, supply chain disruptions from material bans, and reputational damage from sustainability failures. Proactive adoption positions companies for long-term success. - Q: How do we balance performance with recyclability?

Modern materials and design techniques increasingly allow both high performance and recyclability. Focus on application-specific requirements rather than over-engineering. Use life cycle assessment tools to optimize total environmental impact. Engage early with material suppliers to identify innovative solutions. This comprehensive guide provides the foundation for implementing circular design strategies that ensure EPR compliance while driving business value. As regulations continue evolving, maintaining awareness through platforms like C2P and working with compliance experts ensures your design strategies remain current and effective. The transition to circular design isn’t just about compliance – it’s about building competitive advantage in the sustainable economy of tomorrow.

Stay Ahead Of Regulatory Changes in Corporate Sustainability

Want to stay ahead of regulatory developments in sustainability?

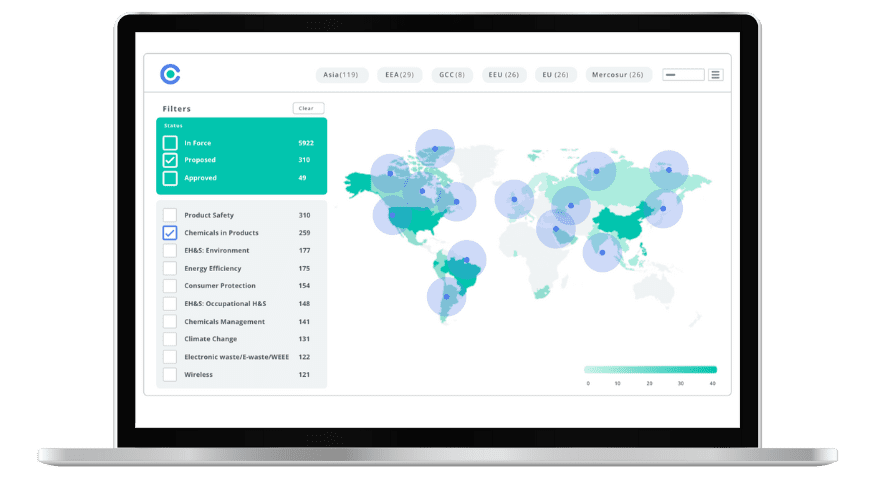

Accelerate your ability to achieve, maintain & expand market access for all products in global markets with C2P – your key to unlocking market access, trusted by more than 300 of the world’s leading brands.

C2P is an enterprise SaaS platform providing everything you need in one place to achieve your business objectives by proving compliance in over 195 countries.

C2P is purpose-built to be tailored to your specific needs with comprehensive capabilities that enable enterprise-wide management of regulations, standards, requirements and evidence.

Add-on packages help accelerate market access through use-case-specific solutions, global regulatory content, a global team of subject matter experts and professional services.

- Accelerate time-to-market for products

- Reduce non-compliance risks that impact your ability to meet business goals and cause reputational damage

- Enable business continuity by digitizing your compliance process and building corporate memory

- Improve efficiency and enable your team to focus on business critical initiatives rather than manual tasks

- Save time with access to Compliance & Risks’ extensive Knowledge Partner network

Simplify Corporate Sustainability Compliance

Six months of research, done in 60 seconds. Cut through ESG chaos and act with clarity. Try C&R Sustainability Free.