Global GHS Implementation Differences by Country: A Definitive Guide for Multinational Compliance Teams

THIS BLOG WAS WRITTEN BY THE COMPLIANCE & RISKS MARKETING TEAM TO INFORM AND ENGAGE. HOWEVER, COMPLEX REGULATORY QUESTIONS REQUIRE SPECIALIST KNOWLEDGE. TO GET ACCURATE, EXPERT ANSWERS, PLEASE CLICK “ASK AN EXPERT.”

The Globally Harmonized System (GHS) promised to simplify chemical safety worldwide. Yet despite its name, GHS implementation remains anything but globally harmonized. While over 83 countries have adopted some form of GHS, the system’s “building block” approach has created a complex patchwork of regulations that can trap even experienced compliance professionals.

For manufacturers operating across borders, these differences aren’t academic—they’re costly operational realities. A chemical classified as Category 2 flammable liquid in one country might fall into Category 3 in another. An SDS that’s perfectly compliant in the United States could face rejection in Canada for missing bilingual requirements. Understanding these nuances isn’t just about regulatory compliance; it’s about maintaining market access and avoiding the substantial penalties that come with getting it wrong.

This guide cuts through the complexity to deliver the granular, technical insights that multinational compliance teams need to navigate GHS implementation differences across the EU, US, Canada, China, and Japan—complete with specific classification thresholds, labeling variations, and practical compliance strategies.

Understanding the GHS Building Block Philosophy

The UN’s decision to structure GHS as a flexible “building block” system fundamentally shapes why we see such dramatic variations in implementation. Rather than mandating a rigid, universal framework, GHS allows countries to select which hazard classes, classification criteria, and communication elements best align with their existing regulatory structures and national priorities.

This approach emerged from practical necessity. Countries like the United States had decades of established chemical safety regulations under OSHA’s Hazard Communication Standard, while the EU operated under a completely different classification and labeling framework. Rather than forcing wholesale regulatory replacement, the building block approach enabled gradual harmonization while respecting national sovereignty over workplace and environmental safety standards.

However, this flexibility creates significant challenges for multinational manufacturers. Each country’s GHS adoption reflects a careful balance between international harmonization and domestic regulatory priorities, resulting in a complex landscape where seemingly identical chemical products require distinctly different safety documentation and labeling approaches across borders.

The implications extend beyond mere paperwork. When China implements different flash point thresholds for flammable liquid classification, or when Canada requires unique hazard classes not recognized elsewhere, manufacturers must maintain multiple classification systems, SDS formats, and labeling approaches—multiplying compliance costs and complexity while increasing the risk of costly errors.

European Union: CLP Regulation Deep Dive

The EU’s Classification, Labelling and Packaging (CLP) Regulation represents one of the most comprehensive and stringent GHS implementations globally, building upon GHS Revision 7 while incorporating distinctly European elements that set it apart from other major jurisdictions.

CLP’s Unique Framework Elements

The CLP Regulation goes beyond basic GHS requirements by maintaining harmonized classification and labeling lists for over 4,000 substances, creating binding classifications that override company self-classification for covered chemicals. This centralized approach provides regulatory certainty but requires constant monitoring of updates to Annex VI, which can reclassify substances without prior notice to manufacturers.

EUH (European Union Hazard) statements represent another critical distinction. These supplementary hazard statements address risks not covered by standard GHS hazard statements, including specific warnings for substances like glutaraldehyde (EUH071: “Corrosive to the respiratory tract”) and certain chromates (EUH201: “Contains chromium(VI). May produce an allergic reaction”).

The regulation also mandates comprehensive environmental hazard classification, implementing all GHS environmental hazard classes including aquatic toxicity categories that remain optional under US OSHA HCS. This creates significant classification differences for chemicals with environmental impacts, particularly industrial solvents and surfactants commonly used in manufacturing.

Technical Classification Differences

CLP implements more stringent classification criteria in several key areas. For acute toxicity, the regulation provides detailed guidance on mixture calculations that often result in more conservative classifications compared to simplified approaches used elsewhere. Similarly, CLP’s implementation of aspiration hazard classification includes Category 2 (which covers substances with viscosity ≤ 20.5 mm²/s at 40°C), a category not consistently implemented across all GHS jurisdictions.

The regulation’s integration with REACH also creates unique obligations. Chemical safety assessments under REACH must align with CLP classifications, and any resulting exposure scenarios must appear in extended safety data sheets—requirements not found in other GHS implementations.

SDS Requirements Under CLP

European SDSs must include comprehensive information in Section 15 (Regulatory information) covering not just CLP obligations but also REACH registration status, authorization requirements, and restriction conditions. Section 1.4 must include a 24-hour emergency telephone number, and Section 2.3 must address “other hazards” including PBT/vPvB properties and endocrine disrupting properties where applicable.

The regulation requires SDSs to be updated whenever new information becomes available that might affect risk management measures, creating a more dynamic compliance obligation than jurisdictions with fixed update cycles.

United States: OSHA HCS Implementation

The US Occupational Safety and Health Administration’s Hazard Communication Standard represents a distinctly American approach to GHS implementation, focusing primarily on workplace safety while deliberately excluding environmental considerations that feature prominently in other jurisdictions.

OSHA HCS Scope and Limitations

OSHA’s implementation, currently aligning with GHS Revision 7 (with select elements from Revision 8), covers only workplace hazards, explicitly excluding environmental hazards, consumer products, and transportation-related risks covered by DOT regulations. This narrow focus creates significant gaps compared to comprehensive implementations like the EU’s CLP Regulation.

The standard makes SDS sections 12-15 optional, recognizing that OSHA lacks jurisdiction over environmental protection, ecological information, disposal considerations, and transportation requirements. This creates a fundamental structural difference from other major jurisdictions where these sections are mandatory and subject to specific content requirements.

Unique OSHA HCS Requirements

Despite its limitations, OSHA HCS includes several unique requirements that don’t appear in other GHS implementations. The standard requires specific language for hazard statements and precautionary statements that sometimes differs from UN model language, particularly for physical hazards where OSHA has incorporated existing US test methods and criteria.

The upcoming alignment with GHS Revision 7/8, with compliance deadlines extending from 2026 to 2028, will introduce new requirements for aerosol classification and updated precautionary statements while maintaining OSHA’s focus on workplace hazards only.

Classification Criteria Nuances

OSHA’s implementation of flammable liquid classification maintains traditional US approaches, with Category 4 flammable liquids (flash point >60°C and ≤93°C) included despite being absent from some other jurisdictions. Similarly, combustible dust hazards receive specific attention under OSHA HCS, reflecting US industrial safety priorities.

The standard’s approach to mixture classification often relies on simplified calculation methods that can produce different results from the more detailed approaches required under CLP, particularly for acute toxicity and environmental hazards (where OSHA classification isn’t required).

Canada: WHMIS 2015 Nuances

Canadian WHMIS 2015 regulations demonstrate how a jurisdiction can embrace GHS principles while maintaining distinctly national characteristics that reflect specific Canadian workplace safety priorities and linguistic requirements.

Bilingual Requirements and Cultural Considerations

WHMIS 2015 mandates bilingual (English and Canadian French) safety data sheets and labels, creating unique compliance obligations not found elsewhere. This isn’t simply translation—Canadian French chemical terminology often differs from European French, requiring specialized expertise and validation to ensure regulatory compliance.

The bilingual requirement extends to all hazard communication elements, including pictograms (which must include bilingual text where applicable), signal words, hazard statements, and precautionary statements. Supplier identification must appear in both languages, and emergency contact information must provide bilingual support capability.

Unique Canadian Hazard Classes

WHMIS 2015 includes several hazard classes not implemented in other major jurisdictions, reflecting specific Canadian workplace safety concerns. Biohazardous infectious materials classification addresses laboratory and healthcare workplace risks, while simple asphyxiant classification covers inert gases that can displace oxygen in confined spaces.

Combustible dusts receive specific treatment under WHMIS 2015, with requirements for hazard identification and communication that go beyond most other GHS implementations. This reflects Canadian industrial safety experience with dust explosion risks in grain handling, mining, and manufacturing sectors.

Classification and Labeling Differences

Canadian implementation of acute toxicity classification includes specific provisions for test data interpretation that can result in different classifications from US or EU approaches, particularly for mixtures containing multiple toxic components. The calculation methods prescribed under WHMIS 2015 often produce more conservative (more hazardous) classifications.

Label requirements include specific Canadian elements such as hatching requirements for pictogram borders and specific placement requirements for bilingual text that create unique design challenges for manufacturers serving multiple North American markets.

Compliance Timeline Pressures

The December 2025 deadline for full alignment with GHS Revision 7/8 creates significant pressure for companies currently operating under earlier WHMIS versions. This timeline coincides with similar updates in the US, creating resource allocation challenges for companies serving both markets simultaneously.

China: GB Standards Framework

China’s implementation of GHS through its GB (Guobiao) national standards system reflects the country’s rapid industrial development and unique regulatory approach to chemical safety, creating specific requirements that often surprise multinational companies entering Chinese markets.

GB Standards Context and Authority

Chinese GHS implementation operates through multiple GB standards, with GB 30000.2-30000.29 covering classification and labeling of chemicals. These standards carry the force of law when referenced in regulatory requirements, but their application can vary across different ministries and regulatory contexts.

The Chinese approach emphasizes integration with existing Chinese chemical safety frameworks, including requirements for chemical registration and notification that don’t exist in other major GHS jurisdictions. This creates layered compliance obligations where GHS classification and labeling represents just one element of broader chemical regulatory requirements.

Technical Differences in Chinese Implementation

Chinese flash point criteria for flammable liquid classification sometimes differ from international approaches, reflecting integration with Chinese fire safety codes and storage requirements. These differences can result in substances classified differently in China compared to EU or US implementations, particularly for borderline cases near classification boundaries.

Chinese pictogram and labeling requirements include specific size and placement requirements that reflect Chinese workplace safety priorities and worker protection standards. Text requirements for Chinese labels must use simplified Chinese characters and include specific supplier identification information formatted according to Chinese business registration requirements.

Integration with Broader Chemical Regulation

Unlike pure GHS implementations, Chinese standards must integrate with broader chemical safety frameworks including environmental protection requirements, workplace safety standards, and chemical inventory obligations. This creates complex compliance scenarios where GHS classification affects multiple regulatory obligations simultaneously.

The Chinese approach to mixture classification often requires additional data beyond basic GHS requirements, particularly for complex industrial mixtures common in manufacturing and processing applications.

Japan: JIS Standards Approach

Japan’s implementation through Japanese Industrial Standards (JIS) reflects the country’s methodical approach to regulatory harmonization, balancing international alignment with Japanese industrial safety traditions and regulatory structures.

JIS Framework and Implementation

Japanese GHS implementation operates primarily through JIS Z 7252 (classification) and JIS Z 7253 (labeling), which align closely with GHS principles while incorporating specifically Japanese elements. The Japanese approach emphasizes voluntary adoption supported by government guidance, creating a different compliance dynamic from mandatory implementations elsewhere.

This voluntary framework can create uncertainty for multinational companies, as different Japanese companies and industry sectors may adopt GHS requirements at different rates and to different degrees. However, major Japanese manufacturers and international companies operating in Japan typically follow JIS requirements fully.

Technical Aspects of Japanese Implementation

Japanese classification criteria closely follow UN GHS recommendations but occasionally reflect Japanese regulatory preferences, particularly for hazards relevant to Japanese industrial processes and workplace conditions. Aspiration hazard Category 2 implementation varies, with some Japanese applications omitting this category consistent with practices in other Asian markets.

Japanese labeling requirements include specific provisions for text size, color contrast, and placement that reflect Japanese workplace safety standards and visual communication preferences. These requirements can create unique design challenges for labels intended for Japanese markets.

Testing and Data Requirements

Japanese implementation often emphasizes specific test methods and data quality requirements that reflect Japan’s rigorous approach to technical standards. This can create situations where classification decisions require Japanese-specific test data or validation, particularly for complex mixtures or borderline classification cases.

The integration with broader Japanese chemical regulatory frameworks, including chemical inventory and notification requirements, creates compliance scenarios where GHS implementation connects to multiple regulatory obligations.

Critical Classification Threshold Differences

The devil in GHS implementation lies in the details—specifically, the numerical thresholds that determine hazard classifications. These seemingly technical differences can dramatically impact product labeling, safety data sheet content, and regulatory obligations across jurisdictions.

Flammable Liquid Classification Thresholds

While all major jurisdictions recognize standard GHS flammable liquid categories, the specific flash point thresholds and test methods can vary significantly:

- Category 1 (Extremely flammable): Universal agreement exists for flash point <23°C and initial boiling point ≤35°C.

- Category 2 (Highly flammable): Flash point <23°C and initial boiling point >35°C—consistent across jurisdictions.

- Category 3 (Flammable): Here differences emerge. Most jurisdictions use flash point ≥23°C and ≤60°C, but specific test methods and vapor pressure considerations can vary.

- Category 4 (Combustible): Flash point >60°C and ≤93°C. This category is implemented in the US and Canada but not universally adopted, creating classification differences for industrial solvents and heating oils.

Chinese GB standards sometimes incorporate additional fire safety considerations that can affect borderline classifications, while EU CLP regulation integrates these classifications with broader chemical safety assessments under REACH.

Acute Toxicity Classification Variations

Acute toxicity classification reveals significant implementation differences that affect both workplace safety and regulatory obligations:

Oral LD50 Categories: While the basic threshold ranges remain consistent (Category 1: ≤5 mg/kg, Category 2: >5-50 mg/kg, Category 3: >50-300 mg/kg, Category 4: >300-2000 mg/kg), the calculation methods for mixtures vary considerably.

EU CLP regulation provides detailed mixture calculation guidance that often produces more conservative classifications, while US OSHA HCS allows simplified approaches that may result in less restrictive classifications for complex mixtures.

Canadian WHMIS 2015 includes specific provisions for interpreting animal test data that can affect classification decisions, particularly for substances with limited toxicity data or conflicting study results.

Environmental Hazard Implementation Gaps

Environmental hazard classification represents the largest implementation gap across jurisdictions:

- Aquatic Toxicity: EU CLP implements all four aquatic toxicity categories (Acute categories 1-3, Chronic category 1-4), creating comprehensive environmental hazard coverage. US OSHA HCS excludes environmental hazards entirely, while Canadian WHMIS includes them but with different emphasis and calculation approaches.

- Ozone Depletion: While theoretically covered under GHS, practical implementation varies based on national environmental protection priorities and existing chemical regulatory frameworks.

These environmental hazard gaps create significant compliance challenges for companies producing industrial chemicals, agricultural products, and consumer goods with environmental release potential.

SDS Content Variations Across Jurisdictions

Safety Data Sheet content requirements reveal subtle but critical differences that can determine regulatory compliance across major markets. Understanding these variations requires section-by-section analysis of what specific information must be included, how it should be presented, and which elements are mandatory versus optional.

Section 1: Identification Requirements

Product identification requirements vary significantly across jurisdictions, reflecting different approaches to chemical naming and supplier accountability:

- EU Requirements: Section 1.1 must include the product identifier exactly as it appears on the label, using IUPAC nomenclature for pure substances or distinctive trade names for mixtures. Section 1.2 requires identification of relevant uses and uses advised against, with sufficient detail to enable appropriate risk management. Section 1.4 mandates a 24-hour emergency telephone number, available in the languages of the countries where the product is marketed.

- US Requirements: OSHA HCS requires product identification but provides more flexibility in naming conventions, accepting common chemical names alongside IUPAC nomenclature. Emergency contact information must be provided but doesn’t require 24-hour availability or multilingual capability.

- Canadian Requirements: WHMIS 2015 requires bilingual product identification (English and Canadian French) and emergency contact information capable of providing bilingual support. Supplier identification must include complete Canadian business registration information.

Section 2: Hazard Identification Differences

Section 2 content varies dramatically based on which GHS building blocks each jurisdiction has implemented:

- Classification Completeness: EU SDSs must include all harmonized classifications from Annex VI of CLP regulation, even when company assessment might suggest different classifications. US SDSs include only workplace hazards, excluding environmental classifications entirely. Canadian SDSs include unique Canadian hazard classes like biohazardous infectious materials.

- Hazard Statement Variations: While basic hazard statements follow GHS models, jurisdictions implement different supplementary statements. EU SDSs must include EUH statements where applicable (EUH071 for respiratory tract corrosives, EUH014 for substances reacting violently with water). US SDSs may include OSHA-specific language that differs from UN model statements.

- Section 2.3 Other Hazards: EU requirements for this subsection are particularly comprehensive, requiring disclosure of PBT/vPvB properties, endocrine disrupting properties, and additional classification not resulting in classification (such as dust explosion hazards). Other jurisdictions may have minimal requirements for this subsection.

Sections 12-15: Regulatory Information Gaps

The treatment of sections 12-15 reveals fundamental philosophical differences in GHS implementation:

- US Approach: OSHA HCS makes sections 12 (ecological information), 13 (disposal considerations), 14 (transport information), and 15 (regulatory information) optional, acknowledging that OSHA lacks jurisdiction over these areas. Companies may include this information voluntarily but aren’t required to maintain accuracy or completeness.

- EU Approach: All sections are mandatory, with section 15 requiring comprehensive coverage of CLP classification, REACH registration status, authorization requirements under Annex XIV, and restriction conditions under Annex XVII. Section 12 must include detailed environmental fate and ecological toxicity information where available.

- Canadian Approach: WHMIS 2015 requires these sections but with specifically Canadian content, including references to Canadian environmental regulations, provincial disposal requirements, and Transportation of Dangerous Goods regulations.

Update Requirements and Timing

SDS update obligations create ongoing compliance challenges with different requirements across jurisdictions:

- EU Timing: CLP requires SDS updates “without delay” when new information becomes available that might affect risk management measures or when harmonized classification changes occur through Annex VI updates.

- US Timing: OSHA HCS requires updates within three months of obtaining new information, but only for information affecting workplace hazards covered under the standard.

- Canadian Timing: WHMIS 2015 requires updates within 90 days of obtaining new hazard information, with specific requirements for notifying downstream users of significant changes.

Labeling Requirements by Country

Chemical labeling represents the front line of hazard communication, where GHS implementation differences become immediately visible to workers and emergency responders. These variations reflect different regulatory priorities, worker protection philosophies, and practical workplace considerations.

Core GHS Elements: Universal Yet Different

While all major jurisdictions require standard GHS label elements—product identifier, supplier identification, pictograms, signal words, hazard statements, and precautionary statements—the specific implementation creates distinct compliance requirements:

- Pictogram Implementation: EU labels must use pictograms exactly as specified in CLP regulation, including specific color requirements (black symbol on white background with red border). Canadian labels require “hatching” around pictogram borders for enhanced visibility in industrial environments. Chinese labels may specify different size proportions based on container dimensions.

- Signal Word Requirements: While “Danger” and “Warning” are universal, the hierarchy rules vary. EU implementation follows strict precedence rules where environmental hazards can influence signal word selection, while US implementation considers only workplace hazards in signal word determination.

Country-Specific Mandatory Elements

Beyond core GHS requirements, each major jurisdiction mandates additional label elements that reflect national regulatory priorities:

European Union Additions:

- EUH statements where applicable, positioned according to specific placement rules

- For certain substances: UFI (Unique Formula Identifier) codes for poison center notification

- Specific font size requirements based on package dimensions

- Requirements for additional pictograms for certain hazard combinations

United States Additions:

- Specific OSHA-mandated language for certain workplace hazards

- Requirements for American English spelling and terminology

- Specific supplier identification format requirements

- Optional environmental pictograms if included must not conflict with required workplace pictograms

Canadian Additions:

- Bilingual text requirements (English and Canadian French) for all text elements

- Specific Canadian supplier identification including business number

- Bilingual emergency contact information

- Pictogram hatching requirements for enhanced visibility

Chinese Additions:

- Simplified Chinese character requirements for all text

- Specific Chinese supplier identification format

- Integration with Chinese hazard communication symbols where applicable

- Specific color and contrast requirements adapted for Chinese workplace conditions

Japanese Additions:

- JIS-compliant pictograms with specific sizing and placement requirements

- Japanese language requirements using appropriate technical terminology

- Integration with existing Japanese hazard communication systems

- Specific formatting for Japanese supplier identification

Size, Placement, and Design Requirements

Label design requirements reflect different approaches to visual communication and workplace safety:

- Size Requirements: EU regulations specify minimum pictogram sizes (10mm × 10mm for small packages, with proportional scaling). US requirements focus on readability standards. Canadian requirements must accommodate bilingual text while maintaining pictogram visibility.

- Color and Contrast: While red borders on pictograms are universal, background color requirements and contrast specifications vary. Chinese standards include specific color requirements adapted for different lighting conditions common in Chinese industrial facilities.

- Text Readability: Font size requirements vary based on package dimensions and jurisdiction. Canadian bilingual requirements often force different text layout approaches compared to monolingual markets.

Multi-Jurisdiction Labeling Strategies

Companies serving multiple markets face complex decisions about labeling approaches:

- Lowest Common Denominator: Including all required elements from all target markets creates comprehensive but potentially cluttered labels that may not optimize for any single market.

- Market-Specific Labels: Separate labels for each jurisdiction ensure compliance but increase complexity and costs while creating potential for shipping errors.

- Regional Approaches: Grouping similar requirements (EU/UK, US/Canada/Mexico) can reduce complexity while maintaining compliance, but requires careful analysis of apparent similarities that hide critical differences.

Compliance Deadlines and Enforcement Trends

The dynamic nature of GHS revisions creates a complex landscape of compliance deadlines that multinational companies must navigate across multiple jurisdictions. Understanding these timelines and enforcement approaches is critical for resource allocation and risk management.

Current Transition Timeline Analysis

- United States HazCom 2012 Update: The alignment with GHS Revision 7/8 creates staggered compliance deadlines: 18 months for pure substances (2026) and three years for mixtures (2028). This timeline reflects OSHA’s recognition of the complexity involved in updating classification systems, but creates interim compliance challenges where companies must maintain documentation that meets both current and future requirements.

- Canadian WHMIS 2015: The December 2025 deadline for GHS Revision 7/8 alignment occurs earlier than the US timeline, creating potential compliance gaps for companies serving both markets. Canadian enforcement has historically been more aggressive than US enforcement, making early compliance particularly important.

- EU CLP Updates: The EU’s approach to GHS revision incorporation tends to be more gradual, with updates integrated through regular CLP regulation amendments rather than wholesale revisions. However, ATP (Adaptation to Technical Progress) updates can create sudden compliance requirements when harmonized classifications change.

Enforcement History and Penalty Trends

- US OSHA Enforcement: OSHA’s enforcement of HazCom standards has intensified significantly, with citation values increasing from an average of $7,000 per violation in 2015 to over $15,000 in 2024. The agency has particular focus on SDS availability and accuracy, with repeat violations carrying significantly higher penalties.

- Canadian Provincial Enforcement: Provincial occupational safety authorities demonstrate varying enforcement approaches, with Alberta and Ontario showing particularly aggressive enforcement of WHMIS requirements. Penalties can include both fines and work stoppage orders that create immediate operational impacts.

- EU Member State Variations: Enforcement varies dramatically across EU member states, with Germany, Netherlands, and Nordic countries maintaining particularly rigorous enforcement programs. The potential for criminal liability in some member states creates heightened risk for willful non-compliance.

Emerging Enforcement Patterns

- Focus on Import Controls: Customs authorities increasingly scrutinize chemical imports for GHS compliance, creating border enforcement risks that extend beyond traditional workplace safety enforcement. Non-compliant products face detention, rejection, and potential destruction at significant cost.

- Digital Documentation Requirements: Several jurisdictions now require electronic availability of SDS documents, creating new compliance verification mechanisms and audit capabilities for enforcement agencies.

- Supply Chain Liability: Enforcement agencies increasingly hold importers and distributors liable for upstream GHS compliance failures, creating pressure for enhanced due diligence and supplier qualification programs.

GHS Revision 11: Future Impact Analysis

UNECE published the revised GHS Revision 11 on 12 September 2025, representing the most significant update to the system since its initial implementation, introducing new hazard classes and updated criteria that will cascade through national implementations over the next five years.

New Hazard Classes and Global Impact

- Desensitized Explosives: This new hazard class addresses explosives that have been treated to reduce sensitivity to shock, friction, or heat. Implementation will be particularly relevant for countries with significant mining, construction, or defense industries, requiring new classification approaches and labeling elements.

- Pyrophoric Gases: Recognition of gases that ignite spontaneously in contact with air addresses gaps in coverage for specialized industrial applications. This classification will be particularly relevant for semiconductor manufacturing and specialty chemical production.

- Global Warming Potential: Perhaps the most significant addition, this hazard class addresses climate change concerns by classifying substances based on their global warming potential. Implementation will vary dramatically based on national climate commitments and environmental regulatory frameworks.

Predicted National Adoption Patterns

- Early Adopters: Countries with advanced environmental regulatory frameworks like those in the EU, Canada, and Australia are likely to implement environmental hazard classes quickly, potentially creating competitive advantages for companies that prepare early.

- Industrial Focus: Countries with significant chemical manufacturing industries may prioritize technical hazard classes like desensitized explosives and pyrophoric gases over environmental considerations.

- Developing Economies: Less developed regulatory systems may adopt GHS Revision 11 elements selectively, focusing on workplace safety hazards while deferring environmental classifications.

Strategic Implications for Multinational Companies

- Classification System Updates: Companies must prepare for potential reclassification of existing products under new hazard classes, requiring comprehensive product portfolio reviews and potential reformulation decisions.

- Documentation Overhaul: SDS and labeling systems must be designed to accommodate new hazard classes, pictograms, and warning statements that don’t yet exist in current systems.

- Training Requirements: Workforce education programs must be updated to address new hazard concepts, particularly for environmental hazards that may be unfamiliar to traditional safety professionals.

- Competitive Positioning: Early adoption of GHS Revision 11 elements may provide competitive advantages in markets where environmental consciousness drives purchasing decisions.

Strategic Solutions for Global Compliance

Managing GHS compliance across multiple jurisdictions requires systematic approaches that move beyond reactive compliance to strategic advantage. The most successful multinational companies treat GHS compliance as an integrated business process rather than a regulatory burden.

Dynamic Compliance Framework Development

- Centralized Classification Authority: Establish a single global team responsible for hazard classification decisions, ensuring consistency while maintaining expertise in jurisdictional differences. This team should include both technical safety expertise and regulatory intelligence capabilities to anticipate changes and manage implementation across markets.

- Modular Documentation Systems: Develop SDS and labeling systems that accommodate jurisdictional variations without requiring complete redevelopment for each market. Template systems should allow for automatic population of jurisdiction-specific elements while maintaining core technical accuracy.

- Supplier Integration Programs: Extend GHS compliance requirements throughout supply chains, ensuring that raw material suppliers and co-manufacturers understand and meet jurisdictional requirements. This includes qualification programs, audit protocols, and contractual language that transfers compliance obligations appropriately.

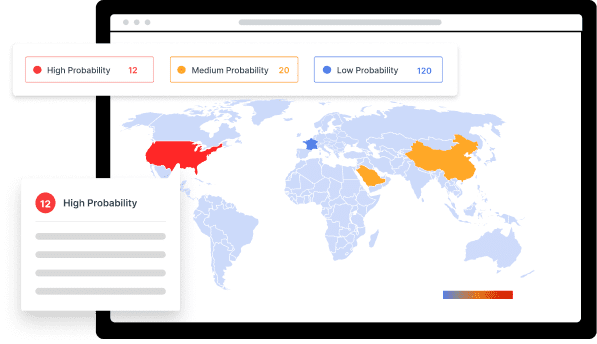

Technology-Enabled Compliance Solutions

- Regulatory Intelligence Systems: Implement automated monitoring of GHS-related regulatory changes across target markets, with alert systems that prioritize changes by potential business impact. This includes tracking not just GHS revisions but also national implementation updates, enforcement guidance changes, and emerging compliance interpretations.

- Classification Decision Support: Deploy software systems that can evaluate chemical properties against multiple jurisdictional criteria simultaneously, flagging potential classification differences and supporting consistent decision-making across global operations.

- Document Lifecycle Management: Establish systems that automatically track SDS and label update requirements across jurisdictions, ensuring timely compliance with varying update obligations while maintaining audit trails for enforcement inquiries.

Risk-Based Prioritization Strategies

- Market Importance Weighting: Focus compliance resources on jurisdictions representing the highest revenue, strategic importance, or enforcement risk. This may mean accepting higher compliance costs in key markets while implementing simplified approaches in secondary markets.

- Product Portfolio Segmentation: Categorize products by compliance complexity and business importance, allowing for differentiated compliance approaches. High-volume, low-margin products may warrant simplified formulations to reduce compliance complexity, while specialty products may justify comprehensive, jurisdiction-specific approaches.

- Enforcement Risk Assessment: Develop frameworks for evaluating enforcement likelihood and penalty severity across jurisdictions and product types. Historical enforcement data, regulatory agency resource allocation, and political priorities all factor into effective risk assessment.

Building Institutional Compliance Expertise

- Cross-Functional Integration: Move beyond traditional EHS ownership of GHS compliance to integrate requirements into product development, supply chain management, and commercial operations. This ensures that compliance considerations influence business decisions rather than merely reacting to them.

- Regulatory Relationship Management: Develop ongoing relationships with regulatory agencies, industry associations, and expert networks across target markets. These relationships provide early warning of regulatory changes and access to authoritative interpretation guidance.

- Continuous Education Programs: Implement training programs that go beyond basic GHS awareness to develop genuine expertise in jurisdictional differences, classification decision-making, and compliance strategy development.

The companies that excel at global GHS compliance treat it as a competitive advantage rather than a cost center. They recognize that superior compliance capabilities enable market access, reduce regulatory risk, and support premium positioning in safety-conscious markets. Most importantly, they understand that GHS expertise is not static—the regulatory landscape continues evolving, requiring ongoing investment in capabilities, systems, and expertise.

For companies serious about global chemical compliance, the choice isn’t whether to invest in comprehensive GHS capabilities—it’s whether to build internal expertise or partner with recognized experts who understand the nuances of global implementation differences. The cost of getting it wrong—in terms of market access, regulatory penalties, and competitive disadvantage—far exceeds the investment required for getting it right.

Frequently Asked Questions

- What are the most significant differences between US and EU GHS implementation? The fundamental difference lies in scope: US OSHA HCS covers only workplace hazards while EU CLP regulation includes comprehensive environmental hazard classification. Structurally, US SDSs make sections 12-15 optional while EU requires all 16 sections with detailed content requirements. The EU also implements EUH statements, harmonized classification lists, and integration with REACH obligations that don’t exist under US regulations.

- How do GHS classification thresholds differ between countries? While basic category definitions remain consistent, calculation methods and criteria interpretation vary significantly. EU CLP regulation provides detailed mixture calculation guidance often resulting in more conservative classifications. Canadian WHMIS includes unique hazard classes like biohazardous infectious materials not found elsewhere. China implements different flash point approaches integrating with local fire safety codes, while Japan may omit certain categories like aspiration hazard Category 2.

- What are the compliance deadlines for GHS updates across major jurisdictions? The US OSHA HCS alignment with GHS Revision 7/8 requires compliance for substances by 2026 and mixtures by 2028. Canada’s WHMIS 2015 deadline for the same updates is December 2025. EU updates occur more gradually through ATP amendments to CLP regulation. These staggered timelines create interim compliance challenges requiring documentation that meets both current and future requirements.

- Why do SDS requirements vary even though GHS is supposed to be harmonized? GHS deliberately uses a “building block” approach allowing countries to select which elements align with their regulatory priorities and existing frameworks. This flexibility enables adoption while respecting national sovereignty over safety standards, but creates variations in mandatory content, classification criteria, and update requirements across jurisdictions.

- How should multinational companies handle bilingual requirements in Canada? Canadian WHMIS requires bilingual (English and Canadian French) SDSs and labels, using specifically Canadian French chemical terminology that differs from European French. Companies need specialized translation expertise, bilingual emergency contact capabilities, and label designs accommodating dual language requirements while maintaining pictogram visibility and regulatory compliance.

- What enforcement risks should companies be aware of for GHS non-compliance? Enforcement intensity has increased significantly across major jurisdictions, with US OSHA citation values doubling since 2015. Beyond traditional workplace safety enforcement, customs authorities increasingly scrutinize imports for GHS compliance, creating border enforcement risks. Supply chain liability is expanding, with importers and distributors held accountable for upstream compliance failures.

- How will GHS Revision 11 impact existing compliance programs? GHS Revision 11 introduces new hazard classes including desensitized explosives, pyrophoric gases, and global warming potential that will require classification system updates and potential product reclassification. National adoption will vary based on environmental regulatory priorities, with EU countries likely implementing environmental hazards faster than workplace-focused jurisdictions.

- What’s the best approach for managing labels across multiple jurisdictions? Companies typically choose between market-specific labels ensuring optimal compliance, lowest-common-denominator approaches including all requirements but potentially creating clutter, or regional strategies grouping similar requirements. The choice depends on product complexity, market importance, and operational capabilities for managing multiple label versions.

- How often do GHS requirements change, and how can companies stay current? UN GHS revisions occur approximately every two years, but national implementation occurs on different timelines creating constant regulatory change. Companies need systematic monitoring systems tracking not just UN updates but national implementation changes, enforcement guidance updates, and emerging compliance interpretations across target markets.

- What role should expert consultants play in GHS compliance strategy? Given the complexity of multi-jurisdictional compliance and constant regulatory evolution, many companies find that partnering with specialized experts provides access to current regulatory intelligence, technical classification expertise, and strategic compliance guidance that would be difficult and expensive to maintain internally. The decision often depends on product complexity, market scope, and internal regulatory expertise capabilities.

Stay Ahead Of Regulatory Changes in GHS Supply Chain Compliance

Want to stay ahead of regulatory developments in GHS Supply Chain Compliance?

Accelerate your ability to achieve, maintain & expand market access for all products in global markets with C2P – your key to unlocking market access, trusted by more than 300 of the world’s leading brands.

C2P is an enterprise SaaS platform providing everything you need in one place to achieve your business objectives by proving compliance in over 195 countries.

C2P is purpose-built to be tailored to your specific needs with comprehensive capabilities that enable enterprise-wide management of regulations, standards, requirements and evidence.

Add-on packages help accelerate market access through use-case-specific solutions, global regulatory content, a global team of subject matter experts and professional services.

- Accelerate time-to-market for products

- Reduce non-compliance risks that impact your ability to meet business goals and cause reputational damage

- Enable business continuity by digitizing your compliance process and building corporate memory

- Improve efficiency and enable your team to focus on business critical initiatives rather than manual tasks

- Save time with access to Compliance & Risks’ extensive Knowledge Partner network

Simplify Corporate Sustainability Compliance

Six months of research, done in 60 seconds. Cut through ESG chaos and act with clarity. Try C&R Sustainability Free.